Power harrow

68

HR6004DR

Maintenance and storage

Cooling system tank

From the working position:

- Park the machine on an even fairly level ground.

- Position intermediate coupling frame tube horizontally

lengthways and crosswise.

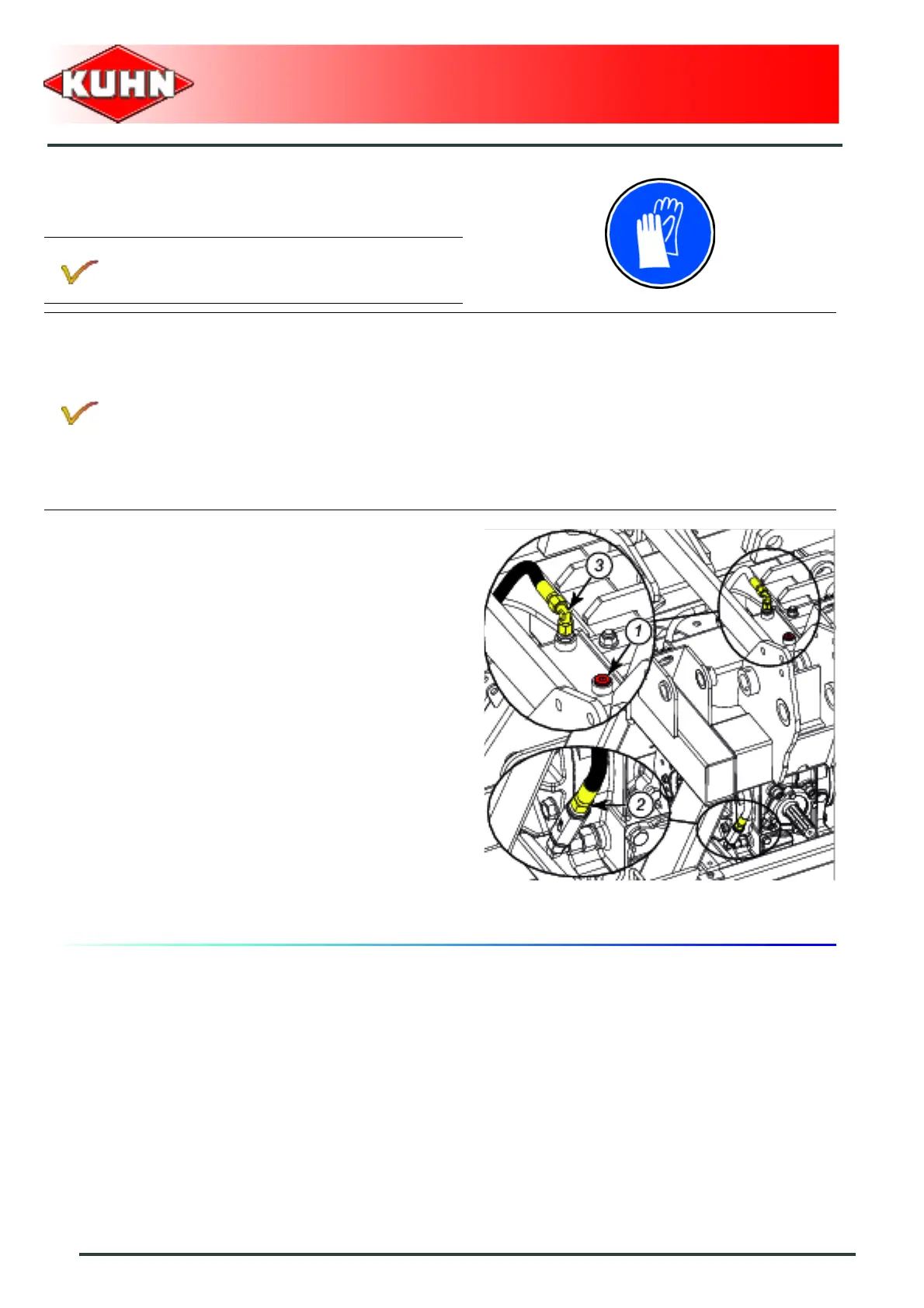

- Remove filler plug (1) and its washer.

- Place container underneath hydraulic hose connector

(2).

- Remove hydraulic hose (2) on valve side.

- Allow oil to drain completely.

- Wait for dripping to stop.

- Clean and reinstall hydraulic hose (2).

- Remove hydraulic hose (3).

- Pour prescribed oil quality through filler plug opening

until top full (1).

- Clean and reinstall hydraulic hose (3).

- Clean and reinstall filler plug (2) and its washer.

Replace if necessary.

Before draining oil, operate the machine for a

few minutes so that the oil warms up.

The cooling system tank contains 5.3 L (1.4 US gal) of SHELL SPIRAX A extreme-pressure oil for

mechanical transmissions with viscosity grade 80W90 and API grade GL5

When refilling it is recommended to use:

For normal use:

- A mineral base oil with viscosity grade SAE 80W90 or 85W140 and API grade GL5

(SHELL SPIRAX A 80W90 or SHELL SPIRAX A 85W140).

For intensive use:

- A synthetic base oil, type PAO (Poly-Alpha-Olefins) with a viscosity grade equivalent to

SAE 80W90 or 85W140 and API grade GL5 (SHELL SPIRAX ASX 75W90).

Loading...

Loading...