Maintenance and storage

Power harrow

HR6004DR

69

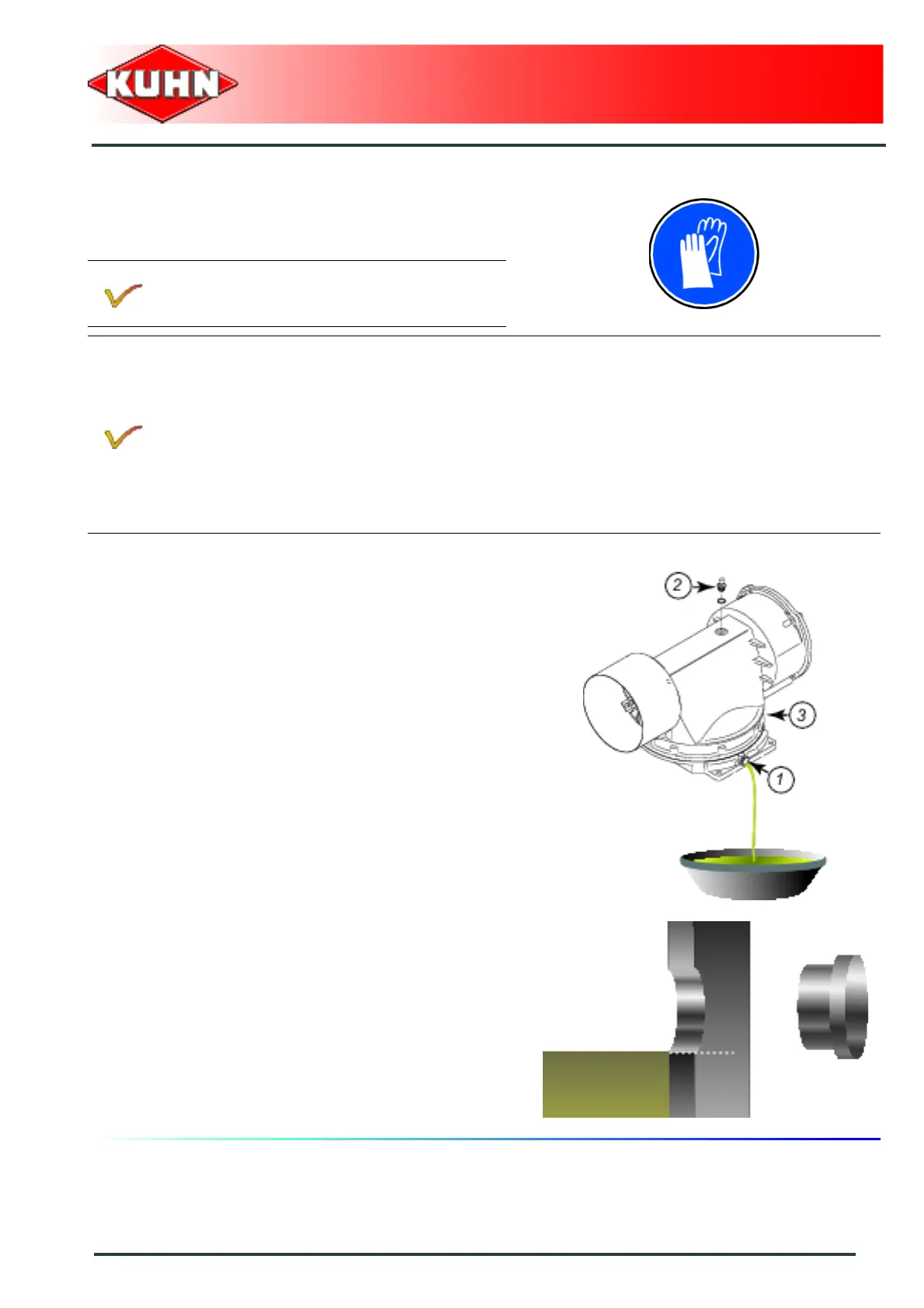

The side gearboxes

From the working position:

- Lower the tractor three-point linkage to rest the

machine on the ground.

- Increase top link length to tilt the machine rearwards.

- Place a container of sufficient capacity under drain

plug (1).

- Remove filler plug (2) and its washer.

- Remove drain plug (1) and its washer.

- Allow oil to drain completely.

- Wait for dripping to stop.

- Clean and reinstall drain plug (1) and its washer.

Replace if necessary.

- Adjust the top link length so that the machine is

horizontal with regards to the ground.

- Pour the correct oil quantity and quality through the

opening of the filler plug (2).

- Clean and reinstall filler plug (2) and its washer.

Replace if necessary.

Checking the oil level:

- Place the machine on level ground.

- Remove level plug (3).

• The oil level must reach the lower edge of level hole

(3).

- Clean and reinstall drain plug (3).

Before draining oil, operate the machine for a

few minutes so that the oil warms up.

Each side gearbox is lubricated with 5 L (1.32 US gal) of SHELL SPIRAX A extreme-pressure gear oil

with viscosity grade 80W90 and API grade GL5.

When refilling it is recommended to use:

For normal use:

- A mineral base oil with viscosity grade SAE 80W90 or 85W140 and API grade GL5

(SHELL SPIRAX A 80W90 or SHELL SPIRAX A 85W140).

For intensive use:

- A synthetic base oil, type PAO (Poly-Alpha-Olefins) with a viscosity grade equivalent to

SAE 80W90 or 85W140 and API grade GL5 (SHELL SPIRAX ASX 75W90).

Loading...

Loading...