SpeedRake

38

SR108 SR110 SR112

Maintenance and storage

2. Maintenance

After the first 10 hours of use and

periodically thereafter

- Check tightness of all bolts and nuts on rake assembly,

particularly on rake wheels and on clevis.

- Check the center retaining clips on the rake wheels for

tightness and adjust as necessary.

- Check transport wheel bolts for tightness. Tightening

torque: 120 ft lbs (163 daNm).

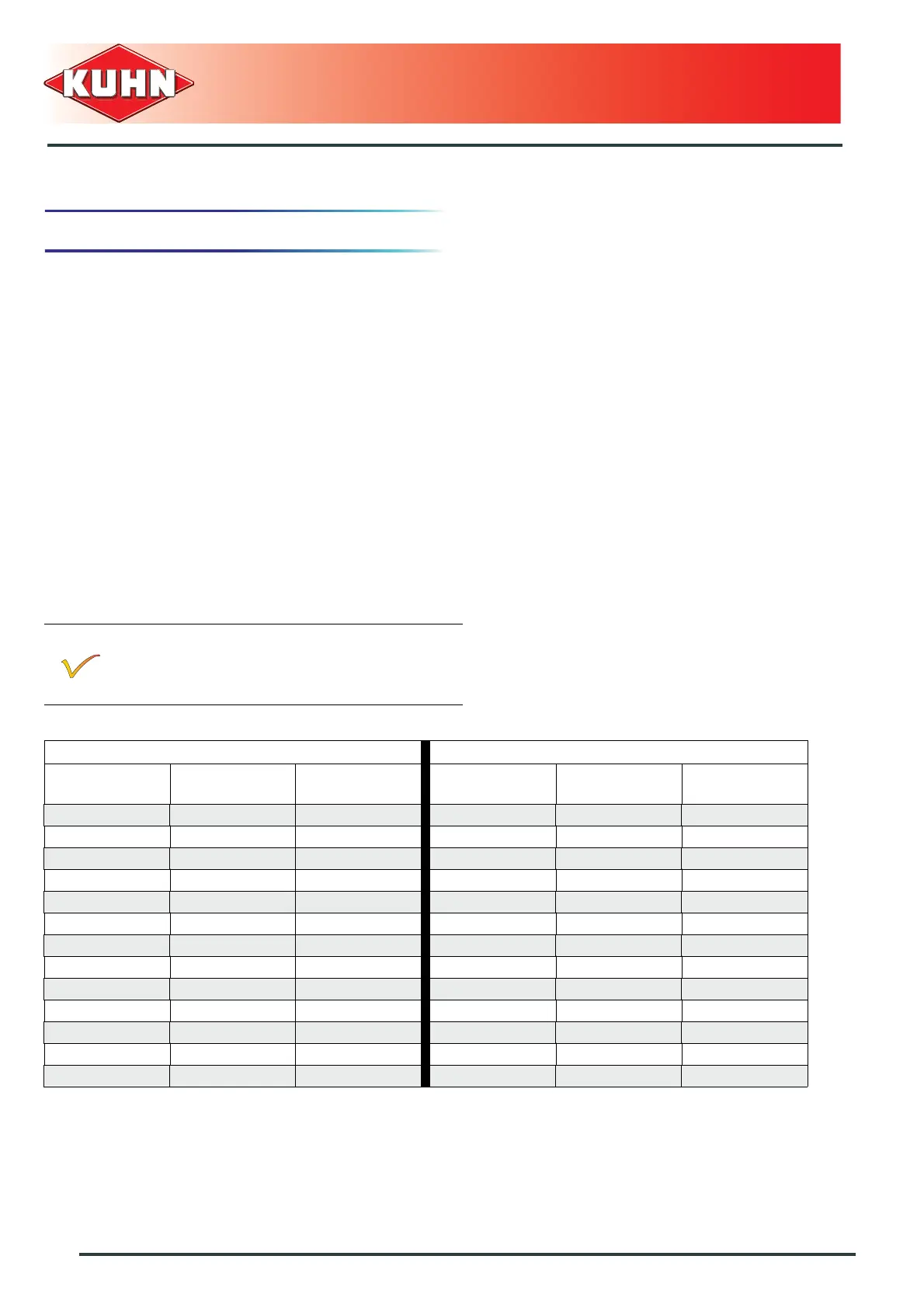

- Check all hydraulic fittings and re-torque as needed;

using the chart for reference. Be sure to lubricate any o-

ring gaskets.

If welding is required on this unit, do not allow the

electrical current to flow through the bearings.

Ground the welder directly to the part being

welded.

37° TUBE FITTINGS AND ADAPTERS ADJUSTABLE O-RING PORT FITTINGS

Tube Size O.D. Thread

Torque - ft lbs

(daNm)

Tube Size O.D. Thread

Torque - ft lbs

(daNm)

2 5/16 7 (0.9) 2 5/16 7 (0.9)

33/89 (1.2)

33/89 (1.2)

4 7/16 12 (1.6) 4 7/16 15 (2.0)

5 1/2 15 (2.0)

5 1/2 19 (2.6)

6 9/16 20 (2.7) 6 9/16 24 (3.3)

8 3/4 39 (5.3)

8 3/4 43 (5.8)

10 7/8 63 (8.5) 10 7/8 48 (6.5)

12 1-1/16 88 (11.9)

12 1-1/16 75 (10.2)

14 1-3/16 103 (13.9) 14 1-3/16 99 (13.4)

16 1-5/16 113 (15.3)

16 1-5/16 123 (16.8)

20 1-5/8 133 (18.0) 20 1-5/8 161 (21.8)

24 1-7/8 167 (22.6)

24 1-7/8 170 (23.0)

32 2-1/2 258 (35.0) 32 2-1/2 240 (27.6)

Loading...

Loading...