5. FUEL SYSTEM

5-2

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• Do not bend or twist control cables. Damaged control cables will not operate smoothly.

• When disassembling fuel system parts, note the locations of O-rings. Replace them with new

ones during reassembly.

• Before float chamber disassembly, loosen the drain screw to drain the residual gasoline into a

clean container.

• After the carburetor is removed, plug the intake manifold side with a clean shop towel to prevent

foreign matters from entering.

• When cleaning the carburetor air and fuel jets, the O-rings and diaphragm must be removed first

to avoid damage. Then, clean with compressed air.

• When the machine is not used for over one month, drain the residual gasoline from the float

chamber to avoid erratic idling and clogged slow jet due to deteriorated fuel.

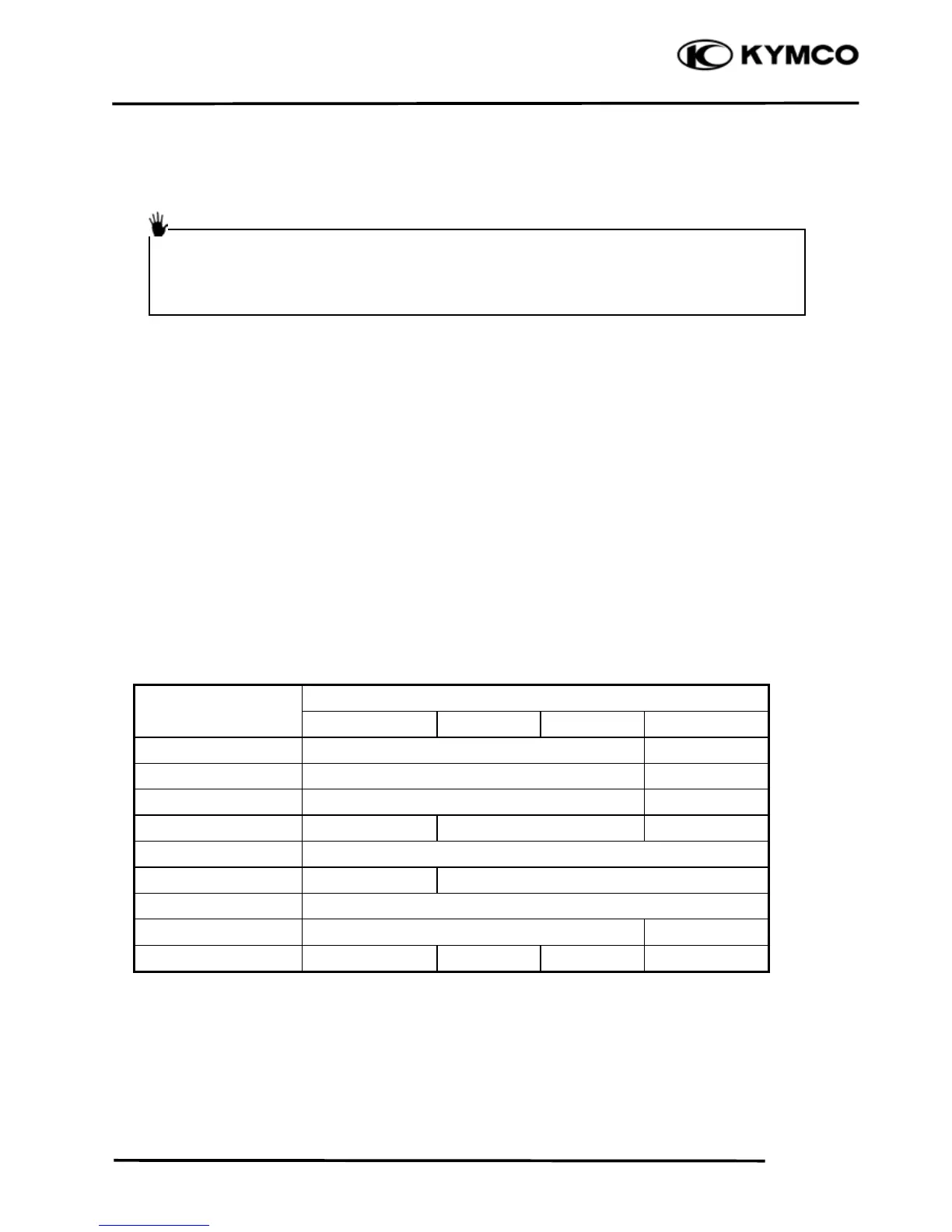

SPECIFICATIONS

Standard

Item

90cc 70cc 50cc-4T 50cc-2T

Type PTE PB

Venturi dia. φ16 φ14

Slow jet No. #40 #38

Main jet No. #80 #85 #80

Adjust method Piston

Idle speed 1800±100 rpm 2000±100rpm

Throttle grip free play 1~4 mm (0.04~0.16 in)

Float level 10.2 mm (0.408 in) 8 mm (0.32 in)

Air screw opening 2 2 2 1±1/4

Gasoline is very dangerous. When working with gasoline, keep sparks and flames away

from the working area.

Gasoline is extremely flammable and is explosive under certain conditions. Be sure to

work in a well-ventilated area.

Loading...

Loading...