6868

RTJ400 User Guide

Chapter 13

Box Joint Procedures - 3/32"

13-19 Now that your joint tightness has been determined, with

the frame pin in position 1, re-clamp pin board 1. Rout in and

out of each template opening.

The eBush must touch one side

of the opening as you enter and the other side as you exit.

A

13-14 Adjust the bit until the tip is level with the center of

the pencil line on pin board 1

A

. Double check that the

bit still rotates freely.

IMPORTANT: Bit height determines the

flushness of the joint, so set your bit properly the first time.

Adjustments for flushness are at the end of the chapter.

13-15 Quick Fit Test To save time and wood, clamp the two

approx. " thick scrap

test

boards in the jig, back to back

A

.

Review the remaining steps in this Chapter.

Rout both

boards in all four frame pin positions 1, 3, 2 and 4. Join the

routed boards and make the joint fit adjustments in the next three

steps. Don’t worry about board edge alignment, the test is for

joint fit only.

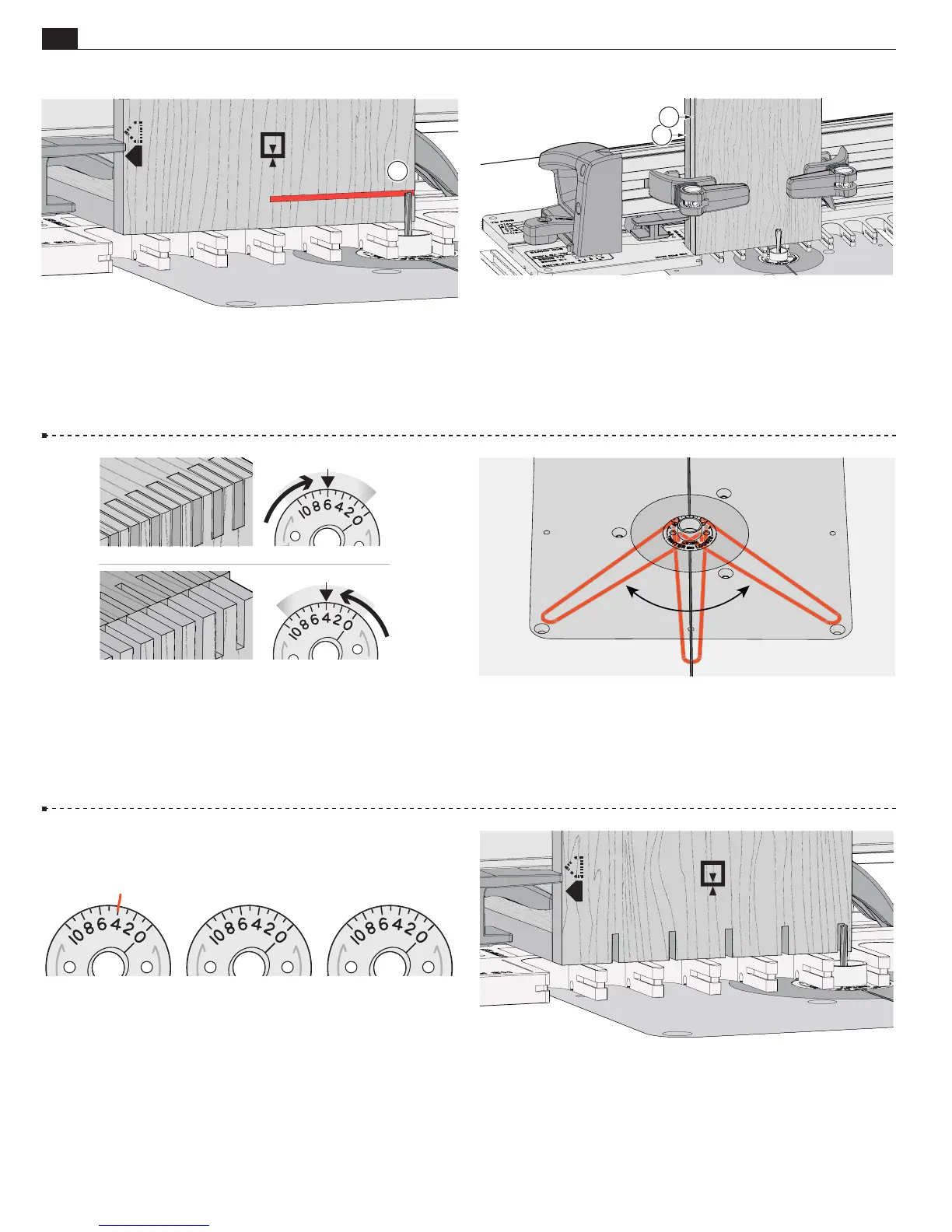

TOO LOOSE TIGHTEN

TOO TIGHT LOOSEN

13-18

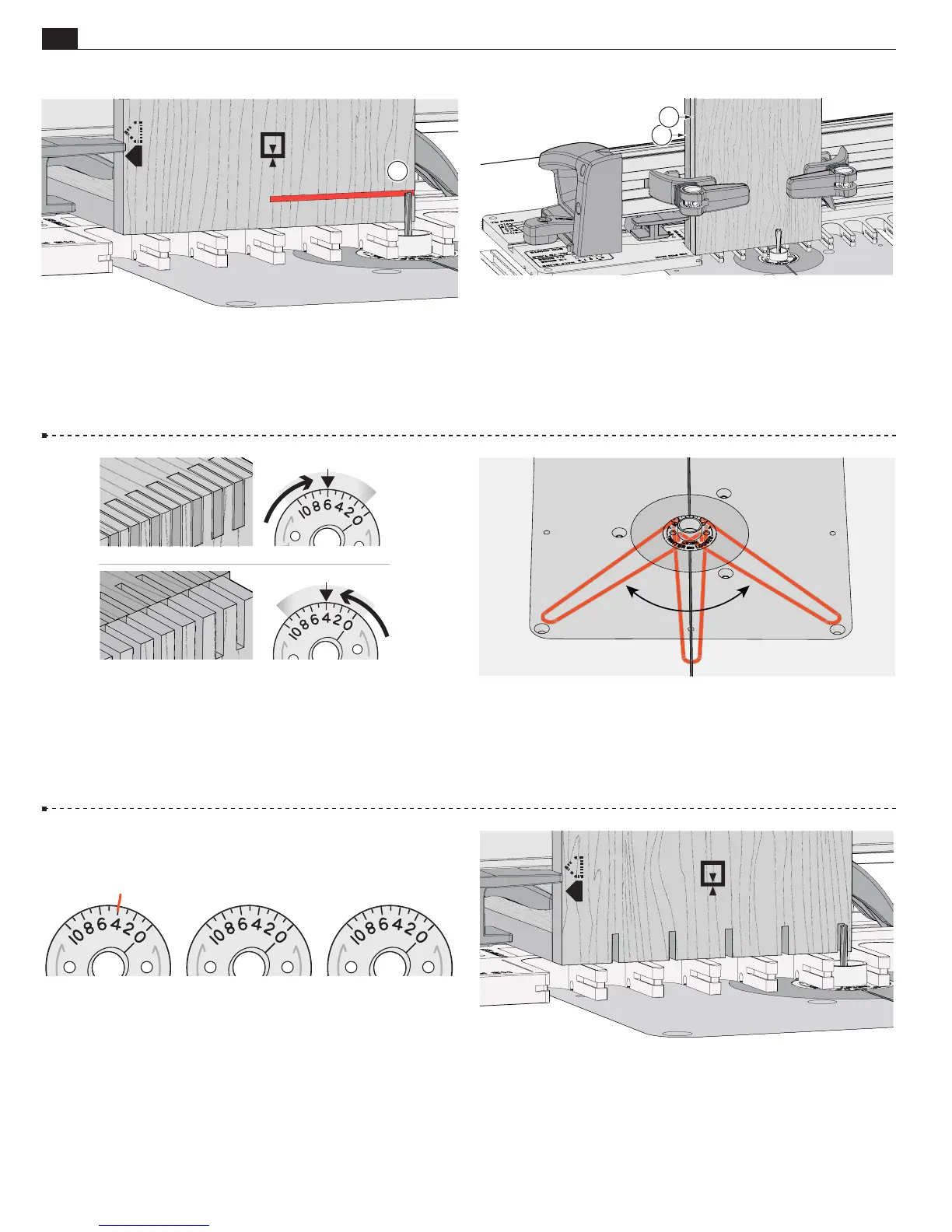

On the eBushes above, record the settings you used to

achieve perfect joint fit. The first eBush is an example of how to

record your setting.

13-16 Joint Fit Adjustment Join the boards, keeping the

same side board edges together. If the joint is too loose, turn the

eBush to a higher number, as shown in the next step. If too tight,

turn the eBush to a lower number.

13-17

Each increment on the eBush changes the joint glue line

fit by 0.002" [0.05mm]. Half an increment, a mere 1000th inch!

Re-tighten the eBush nut after each guide bushing adjustment.

Sample

Leigh 163 Bit

A

A

Loading...

Loading...