Page 18

506270−01 05/09

Start−Up and Charging Procedures

IMPORTANT

If unit is equipped with a crankcase heater, it should

be energized 24 hours before unit start−up to

prevent compressor damage as a result of slugging.

1. Rotate fan to check for binding.

2. Inspect all factory− and field−installed wiring for loose

connections.

3. After evacuation is complete, open both the liquid and

vapor line service valves to release the refrigerant

charge contained in outdoor unit into the system.

4. Replace the stem caps and tighten to the value listed

in table 1.

5. Check voltage supply at the disconnect switch. The

voltage must be within the range listed on the unit’s

nameplate. If not, do not start the equipment until you

have consulted with the power company and the

voltage condition has been corrected.

6. Set the thermostat for a cooling demand. Turn on

power to the indoor indoor unit and close the outdoor

unit disconnect switch to start the unit.

7. Recheck voltage while the unit is running. Power must

be within range shown on the nameplate.

8. Check system for sufficient refrigerate by using the

procedures listed under Testing and Charging

System.

TESTING AND CHARGING SYSTEM

This system uses HFC−410A refrigerant which operates at

much higher pressures than HCFC−22. The pre−installed

liquid line filter drier is approved for use with HFC−410A

only. Do not replace it with components designed for use

with HCFC−22. This unit is NOT approved for use with coils

which use capillary tubes as a refrigerant metering device.

SETTING UP TO CHECK CHARGE

1. Close manifold gauge set valves. Connect the center

manifold hose to an upright cylinder of HFC−410A.

2. Connect the manifold gauge set to the unit’s service

ports as illustrated in figure 2.

low pressure gauge to vapor service port

high pressure gauge to liquid service port

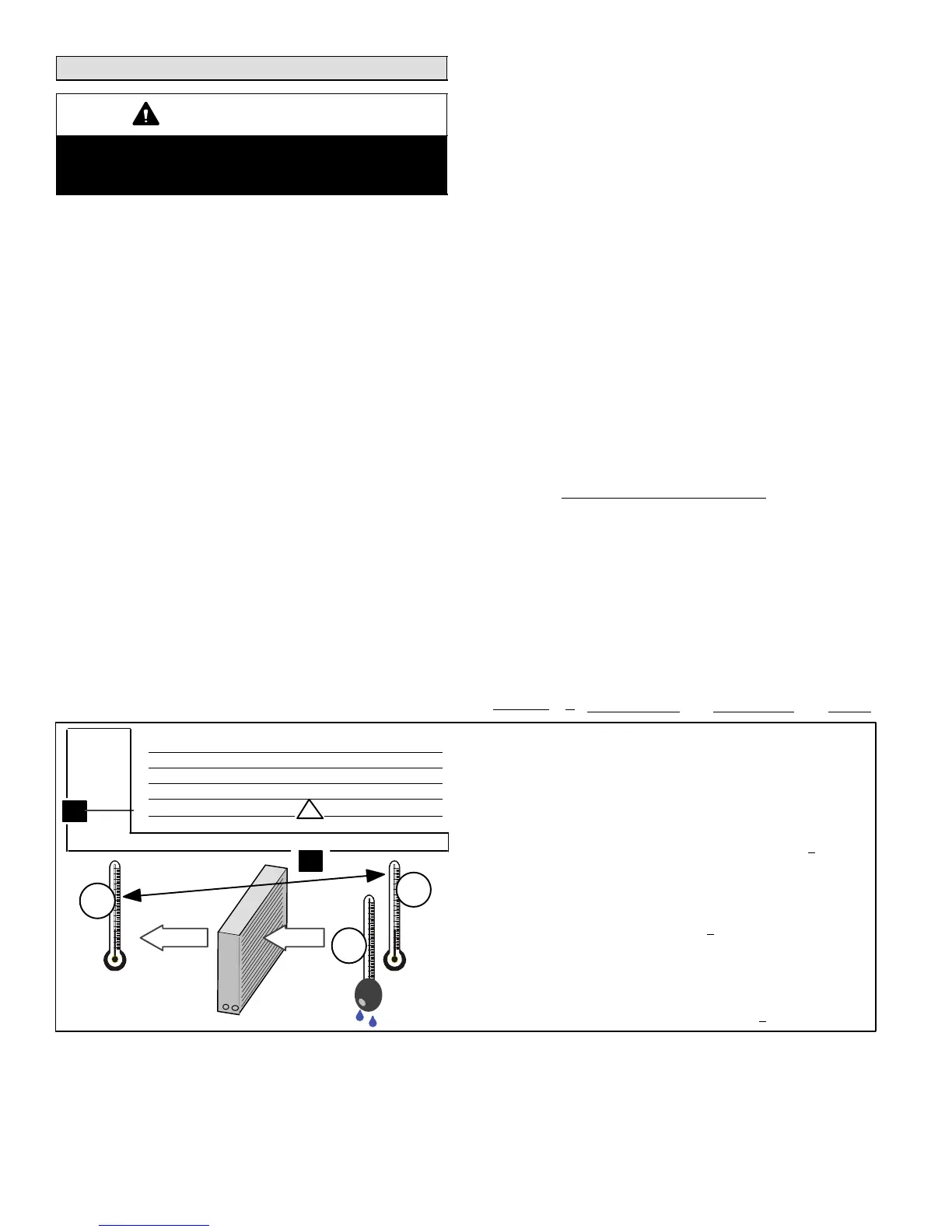

COOLING MODE INDOOR AIRFLOW CHECK

Check airflow using the Delta−T (DT) process using the

illustration in figure 32.

HEATING MODE INDOOR AIRFLOW CHECK

Blower airflow (CFM) may be calculated by energizing

electric heat and measuring:

Temperature rise between the return air and supply air

temperatures at the indoor coil blower unit,

Measuring voltage supplied to the unit,

Measuring amperage being drawn by the heat unit(s).

Then, apply the measurements taken in following formula

to determine CFM:

CFM =

Amps x Volts x 3.41

1.08 x Temperature rise (F)

CALCULATING CHARGE

If the system is void of refrigerant, first, locate and repair

any leaks and then weigh in the refrigerant charge into the

unit. To calculate the total refrigerant charge:

Amount

specified

on

nameplate

Adjust amount. for

variation in line set

length listed on table

in figure 33.

Additional charge

specified per

indoor unit

match−up listed in

table 3.

Total

charge

+ + =

1. Determine the desired DTMeasure entering air temperature

using dry bulb (A) and wet bulb (B). DT is the intersecting value of A

and B in the table (see triangle).

2. Find temperature drop across coilMeasure the coil’s dry bulb

entering and leaving air temperatures (A and C). Temperature Drop

Formula: (T

Drop

) = A minus C.

3. Determine if fan needs adjustmentIf the difference between

the measured T

Drop

and the desired DT (T

Drop

–DT) is within +3º, no

adjustment is needed. See examples: Assume DT = 15 and A temp.

= 72º, these C temperatures would necessitate stated actions:

Cº T

Drop

– DT = ºF ACTION

53º 19 – 15 = 4 Increase the airflow

58º 14 – 15 = −1 (within +3º range) no change

62º 10 – 15 = −5 Decrease the airflow

4. Adjust the fan speedSee indoor unit instructions to increase/

decrease fan speed.

Changing air flow affects all temperatures; recheck temperatures to

confirm that the temperature drop and DT are within +3º.

DT

80 24 24 24 23 23 22 22 22 20 19 18 17 16 15

78 23 23 23 22 22 21 21 20 19 18 17 16 15 14

76 22 22 22 21 21 20 19 19 18 17 16 15 14 13

74 21 21 21 20 19 19 18 17 16 16 15 14 13 12

72 20 20 19 18 17 17 16 15 15 14 13 12 11 10

70 19 19 18 18 17 17 16 15 15 14 13 12 11 10

57 58 59 60 61 62 63 64 65 66 67 68 69 70

Temp.

of air

entering

indoor

coil ºF

INDOOR

COIL

DRY

BULB

DRY

BULB

WET

BULB

B

T

Drop

19º

A

Dry−bulb

Wet−bulb ºF

A

72º

B

64º

C

53º

air flowair flow

All temperatures are

expressed in ºF

Figure 32. Checking Indoor Coil Airflow Guide

Loading...

Loading...