Page 18 - IOM / ROOF-TOP FLEXY™ Series

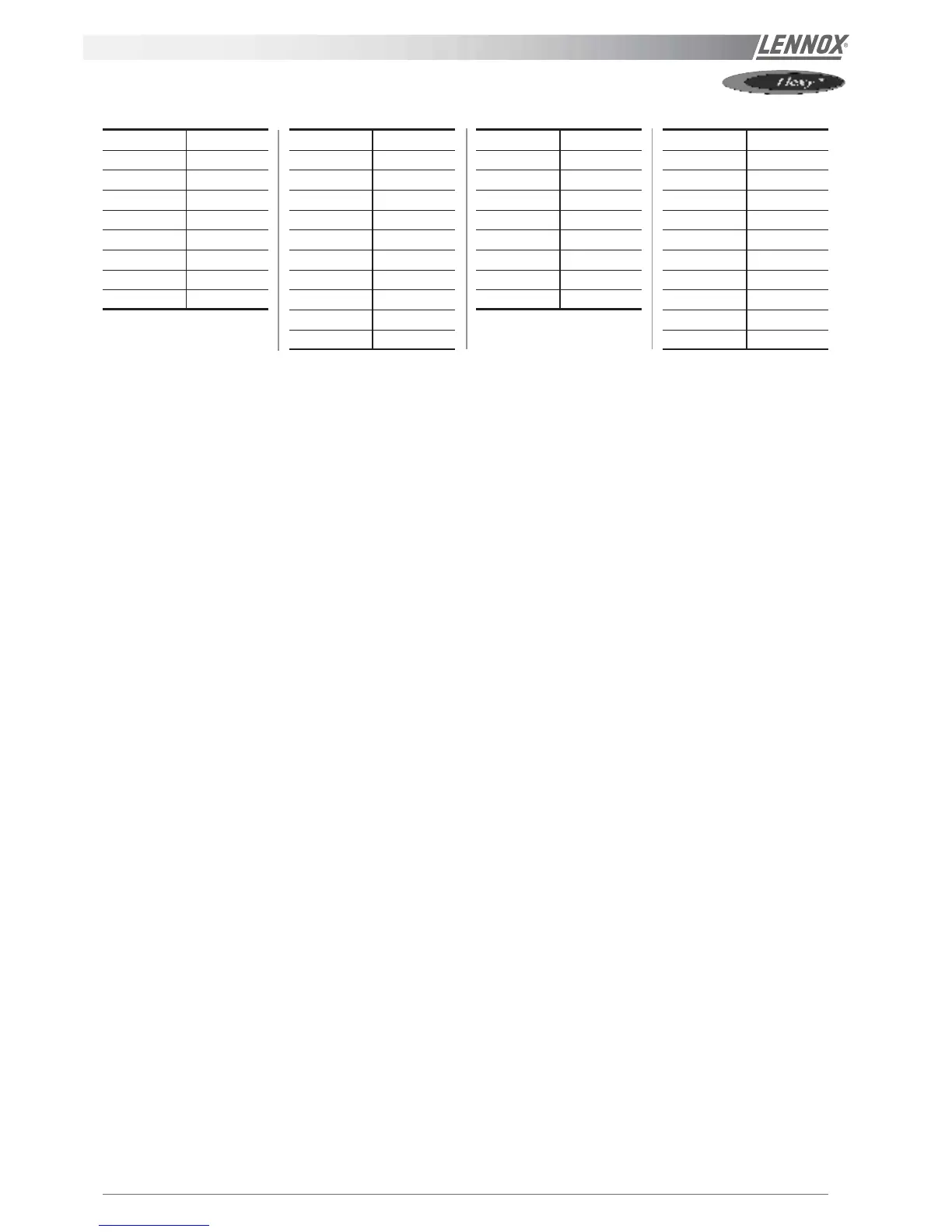

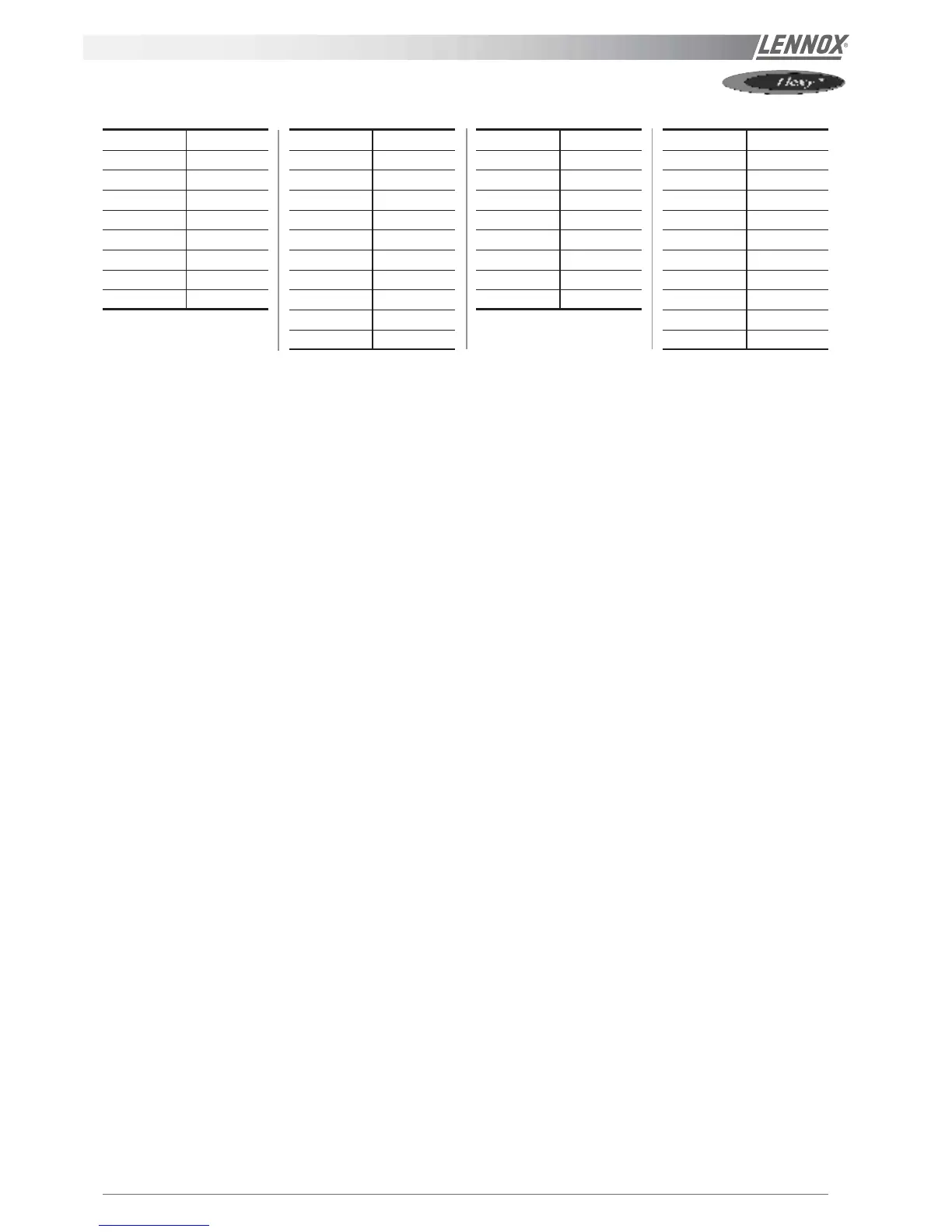

Configuration table LF20

COMMISSIONING

F.A050 11

F.A060 12

F.A070 13

F.A085 14

F.A100 15

F.A120 16

F.A140 17

F.A160 18

F.A190 19

FXA025 20

FXA030 21

FXA035 22

FXA040 23

FXA055 24

FXA070 25

FXA085 26

FXA100 27

FXA110 28

FXA140 29

FXA170 30

F.K050 111

F.K060 112

F.K070 113

F.K085 114

F.K100 115

F.K120 116

F.K140 117

F.K160 118

F.K190 119

FXK025 120

FXK030 121

FXK035 122

FXK040 123

FXK055 124

FXK070 125

FXK085 126

FXK100 127

FXK110 128

FXK140 129

FXK170 130

Switches on KP01

1 = on ....................... Option : pressure pick-up on air 500 pa (on FLEXY™ off = sensor 1000 pa)

2 = on | 3 = off ................... Option : hot water coil

2 = off | 3 = on ................... Option : electrical heater

2 = on | 3 = on ...................Option : gas burner

4 = on ....................... Option : cycle reversing valve, compressors (heat pump)

5 = on ....................... Option : heating of great power / or / pump (except freezing of the hot water coil)

6 = on ....................... Option : fresh air, economiser

7 = on ....................... Option : fresh air, all fresh air

8 = on ....................... Option : KP02 / KP17

POWERING THE UNIT

- Power up the unit by closing the isolator switch (if fitted).

- Close all circuit breakers and power up the unit, remove

the bridge on connector J14 if fitted.

- If now only one of the components rotates in the wrong

direction, disconnect the power supply at the machine's

isolator switch (if fitted) and reverse two of the

component's phases on the terminal within the electrical

panel.

- Check the current drawn against the rated values, in

particular on the supply fan.

- If the readings on the fan are outside the specified limits,

this usually indicates excessive air flow which will affect

the life expectancy and the thermodynamic performan-

ces of the unit. This will also increase the risks of water

ingress into the unit. Refer to the "air flow balancing"

section to correct the problem.

At this point attach the manometers to the refrigerant circuit.

RUN TEST

Start unit in cooling mode

Thermodynamic readings using manometers and prevailing

environmental conditions.

No rated values are given here. These depend on the

environmental conditions both outside and inside the building

during operation. However, an experienced refrigeration

engineer will be able to detect any abnormal machine

operation.

Safety test

- "Dirty filter" detection test : vary the set-point value in

respect to the air pressure value. Observe the response

of the CLIMATIC™.

- Same procedure for detecting "Missing filter" or "Air flow

detection".

- Check the smoke detection function (if fitted).

- Check the Firestat by pressing the test button(if fitted).

- Disconnect the circuit breakers of the outdoor fans and

check the high pressure cut-out points on different

refrigerant circuits.

Reverse cycle test

This test is designed to check the good operation of the 4-

way reversing valves on heat pump reversible systems. Start

the reverse cycle by adjusting the cold or hot temperature

threshold data according to the indoor and outdoor conditions

at the time of test.

Loading...

Loading...