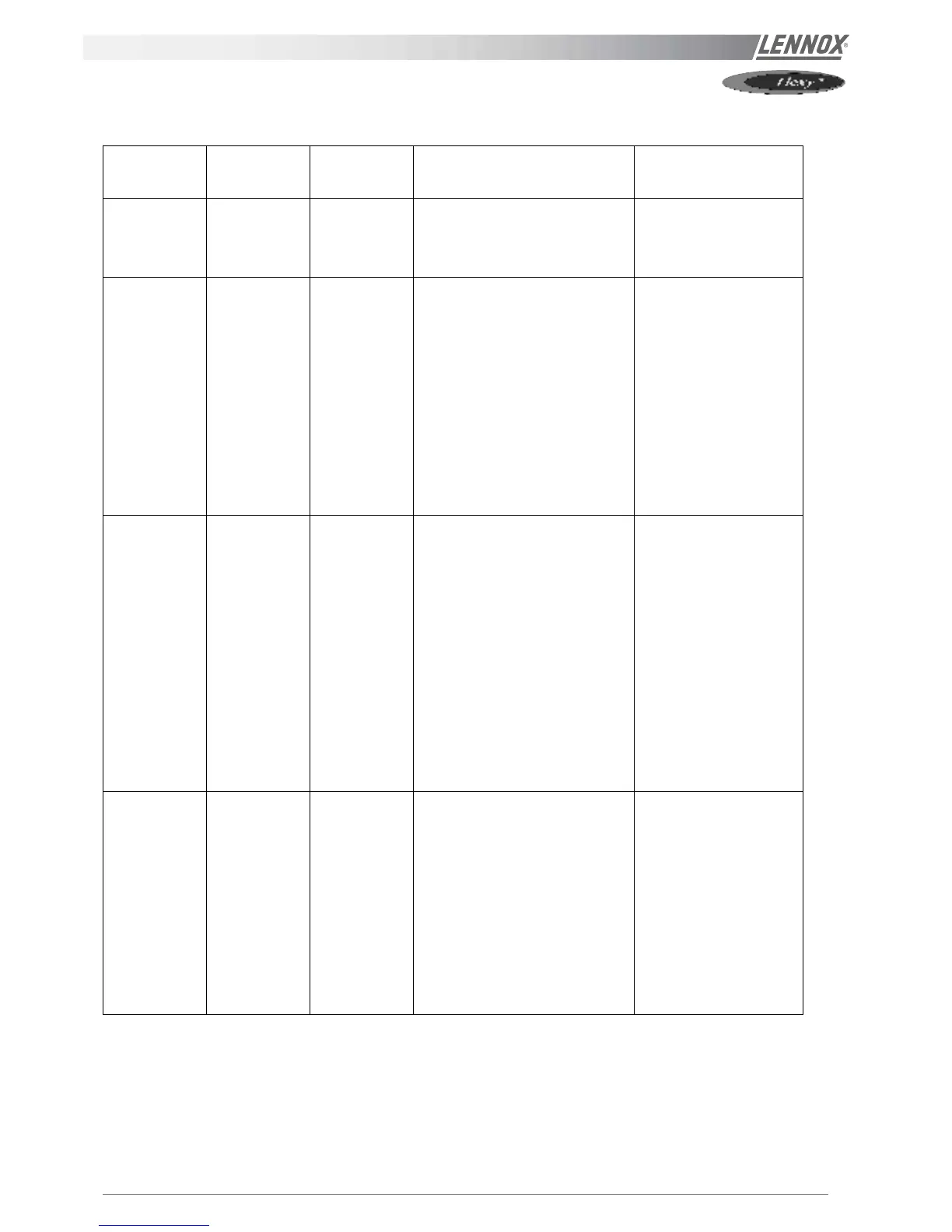

Page 52 - IOM / ROOF-TOP FLEXY™ Series

GAS BURNERS

DIAGNOSTIC TABLE GAS BURNER

STAGES

NORMAL

OPERATION

FAULT ACTIONS SOLUTIONS

Heating

requested

Contactors

KM21-22

engaged

Contactors do

not engage

• Check safety thermostats B29-

30 in the air duct before the gas

heat exchanger

• Replace component

Contactors

KM21-22 are

engaged

Extraction fans

are running

Nothing

happens

• Check the free movement of the

fan wheel

• Check the supply temperature

limitation thermostats B45-46

• Check GAS low pressure

switches B17-18

• Check electrical connection on

the Honeywell control block

and on EF45-46 connection

boards

• Check the fan supply voltage

• Replace thermostat

• Open GAS Supply

• Replace EF 45-46 if

necessary

Extraction fan

ON

After 30

seconds: the

fire-up

electrode must

create sparks

Continuous

ventilation

without sparks

by electrode

• Check position of the fire-up

electrode (refer to preliminary

checks and verifications §1)

• Check the pressure drop at the

pressure switch : It must be

higher than 200 Pa

• Check the good operation of the

pressure switch using an

Ohmmeter and by sucking

through the tube to create a

depression.

• Check the operation the Backfire

thermostat B32-B33

• Re-position the

pressure taping

tube.(§5.d)

• Change the pressure

switch

• Reset or replace the

Thermostat

Continuous

ventilation with

sparks created

by electrode

After 2 seconds

the gas burner

fires-up

After 4 second

the GAS Burner

still not running

and Safety

shutdown by

the Honeywell

Block.

• Check injection pressure during

start-up (value for high heat)

• Check the supply voltage to the

control box (continuous voltage).

Refer to figure 61.

• Remove the control box from the

gas block. Check using an

ohmmeter the solenoid coil of

the GAS block (4 kOhm). Refer

to figure 62

• Remove the air from the

pipe-work

• Adjust the injection

pressure to high heat

value

• Change the control box

if the GAS valve is OK.

• Change the gas valve

control

Loading...

Loading...