Page 14

On heat demand (first or second stage) the switch senses

that the combustion air inducer is operating. It closes a cir-

cuit to the furnace control when pressure inside the cold

end header box decreases to a certain set point.

Set points vary depending on unit size. See tables 8, 9 and

10. The pressure sensed by the switch is negative. If the air

intake vent pipe or outlet vent pipe becomes obstructed

during operation, the switch senses a change of negative

pressure and opens the circuit to the furnace control and

gas valve. A bleed port on the switch allows relatively dry

air in the vestibule to purge switch tubing, to prevent con-

densate build up.

The switch is factory set and is not field adjustable. It is a

safety shut-down control in the furnace and must not be by−

passed for any reason. If switch is closed or by−passed, the

control will not initiate ignition at start up.

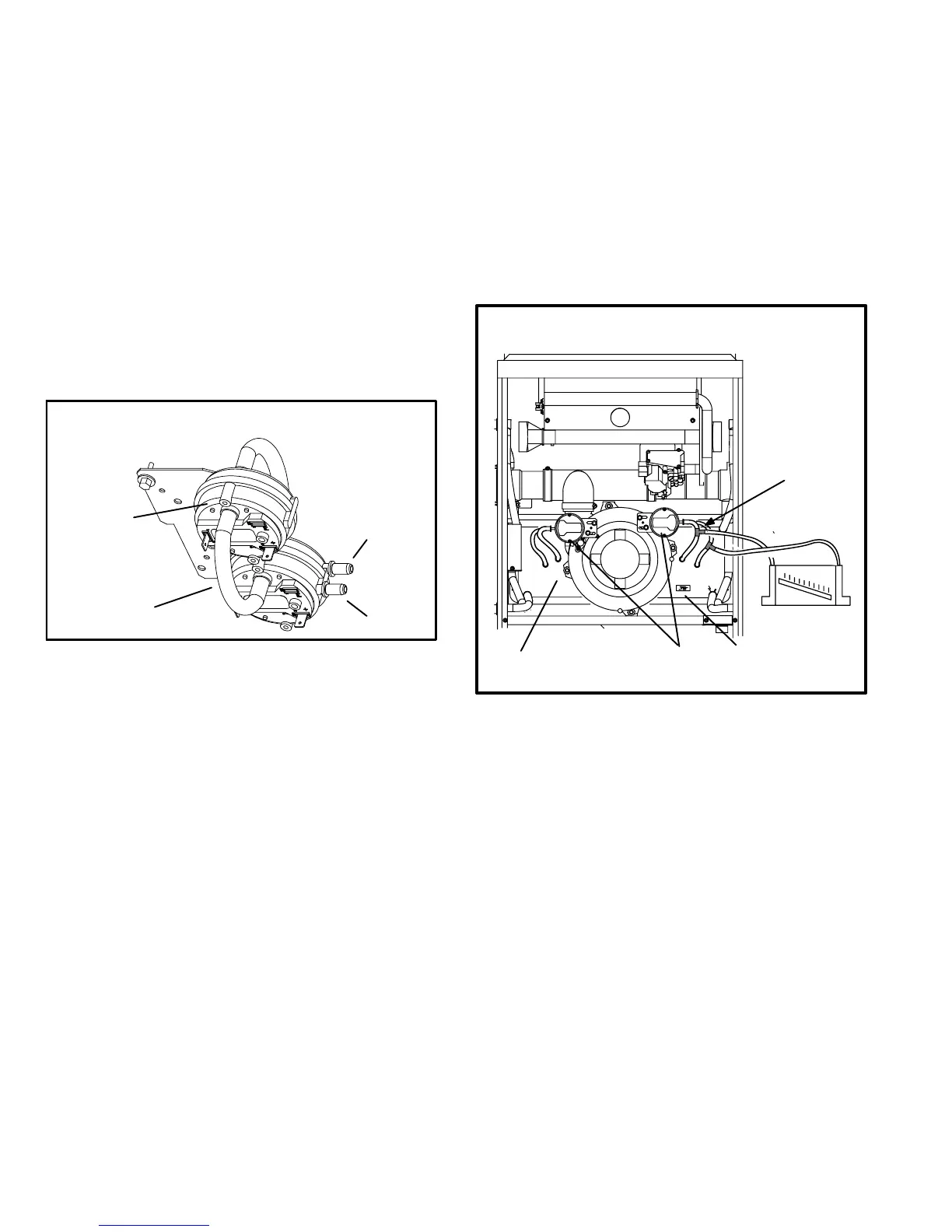

FIGURE 9

DUAL COMBUSTION AIR PROVE SWITCH

G61MP−090, −110 & −135

first stage

second stage

positive

pressure

negative

pressure

To troubleshoot the prove switches, temporarily jumper them.

The unit will not fire with the switches jumpered. Therefore, the

prove switches must be bypassed after the combustion air in-

ducer is activated. This will determine if the prove switches

and furnace are operating properly. However, this may not in-

dicate if the sealed combustion system is operating properly.

Checks of pressure differential can aid in troubleshooting.

When measuring the pressure differential, readings should be

taken at the prove switch. Lack of differential usually indicates

problems in the intake or exhaust piping, but may indicate

problems in the heat exchanger, condensing coil, head-

er boxes, combustion inducer or other components.

Measuring pressure differential

The differential pressure is the difference in pressure mea-

sured across the cold end header box orifice.

1 − Remove thermostat demand and allow unit to cycle

off.

2 − Install a tee in the negative (−) line and a tee in the positive

(+) line running from one of the prove switches to the cold

end header box.

3 − Install a manometer with hose from the negative (−)

side of the manometer to the tee installed in the nega-

tive (−) line and with hose from the positive (+) side of

the manometer to the tee in the positive (+) line.

NOTE − Both sides of the cold end header box are negative.

However the (+) port reads less negative pressure than the

(−) port.

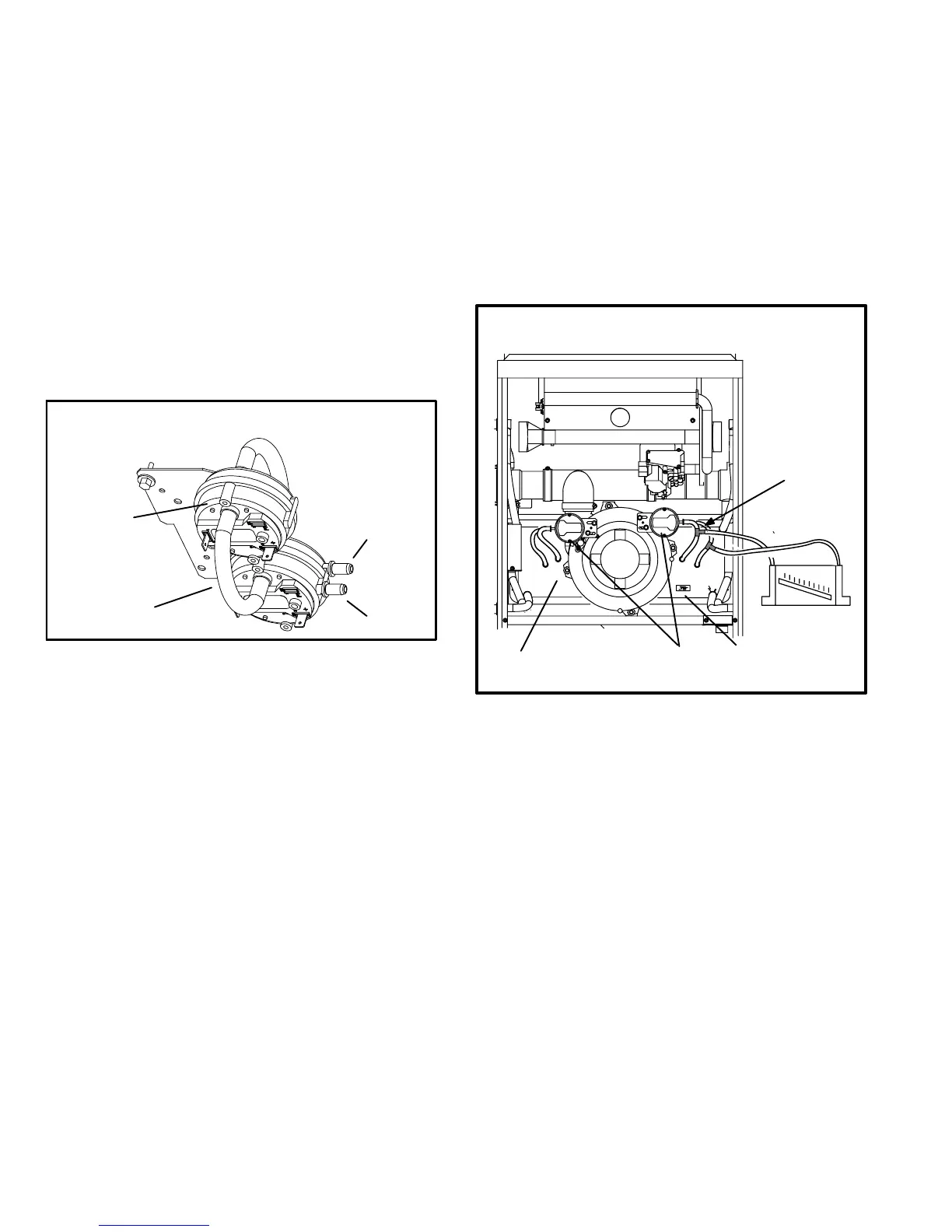

FIGURE 10

Install tee’s in the

negative line and

positive line then

connect hoses to

manometer.

prove switches

orifice size

CAI & COLD END HEADER BOX ASSEMBLY

(−045 & 070 SHOWN)

cold end header box

+

+

_

_

4 − Operate unit and observe manometer reading. Read-

ings will change as heat exchanger warms.

a. Take one reading immediately after start-up.

b. Take a second reading after unit has reached steady

state (approximately 5 minutes). This will be the pres-

sure differential.

The pressure differential should be greater

than those listed in table 8, 9 or 10.

5 − Remove thermostat demand and allow to cycle off.

6 − Remove manometer and tee’s. Reinstall combustion air

sensing hoses to the prove switch.

7 − Repeat steps 1 through 6 for the other prove switch.

Loading...

Loading...