Page 31

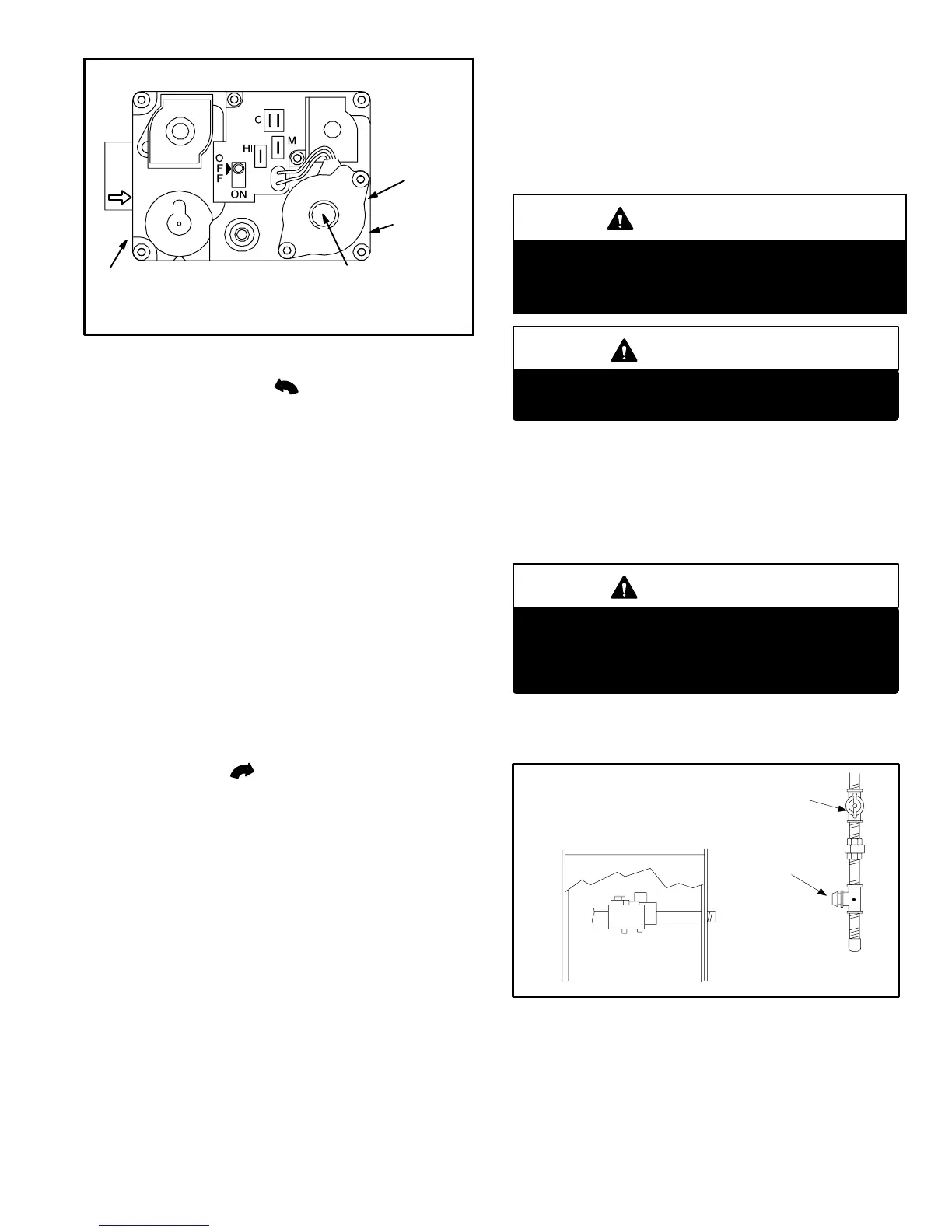

WHITE RODGERS 36E SERIES GAS VALVE

GAS VALVE SHOWN IN OFF POSITION

HIGH FIRE

MANIFOLD

PRESSURE

ADJUSTMENT

ON SIDE

(under cap)

MANIFOLD

PRESSURE

TAP ON SIDE

INLET PRESSURE

TAP ON SIDE

LOW FIRE MANIFOLD

PRESSURE ADJUSTMENT

ON SIDE (under cap)

FIGURE 36

8 − Honeywell VR8205 Gas Valve − Turn knob on gas

valve counterclockwise to ON. Do not force.

White Rodgers 36E Gas Valve − Switch gas valve lever

to ON. See figure 36 for the White Rodgers 36E

valve.

9 − Replace the upper access panel.

10− Turn on all electrical power to to the unit.

11− Set the thermostat to desired setting.

NOTE − When unit is initially started, steps 1 through 11

may need to be repeated to purge air from gas line.

12− If the appliance will not operate, follow the instructions

Turning Off Gas to Unit" and call your service techni-

cian or gas supplier.

Turning Off Gas to Unit

1 − Set the thermostat to the lowest setting.

2 − Turn off all electrical power to the unit if service is to be

performed.

3 − Remove the upper access panel.

4 − Honeywell VR8205 Gas Valve − Turn knob on gas

valve clockwise to OFF. Do not force.

White Rodgers 36E Gas Valve − Switch gas valve le-

ver to OFF.

5 − Replace the upper access panel.

C−Safety or Emergency Shutdown

Turn off unit power. Close manual and main gas valves.

D−Extended Period Shutdown

Turn off thermostat or set to UNOCCUPIED" mode. Close

all gas valves (both internal and external to unit) to guaran-

tee no gas leak into combustion chamber. Turn off power to

unit. All access panels and covers must be in place and se-

cured.

IV−HEATING SYSTEM SERVICE CHECKS

A−C.S.A. Certification

All units are C.S.A. (formally A.G.A. and C.G.A. combined)

design certified without modifications. Refer to the G61MP

Installation Instruction.

B−Gas Piping

CAUTION

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend outside

the furnace cabinet.

WARNING

Do not exceed 600 in−lbs (50 ft−lbs) torque when

attaching the gas piping to the gas valve.

Gas supply piping should not allow more than 0.5"W.C. drop

in pressure between gas meter and unit. Supply gas pipe

must not be smaller than unit gas connection.

Compounds used on gas piping threaded joints should be

resistant to action of liquefied petroleum gases.

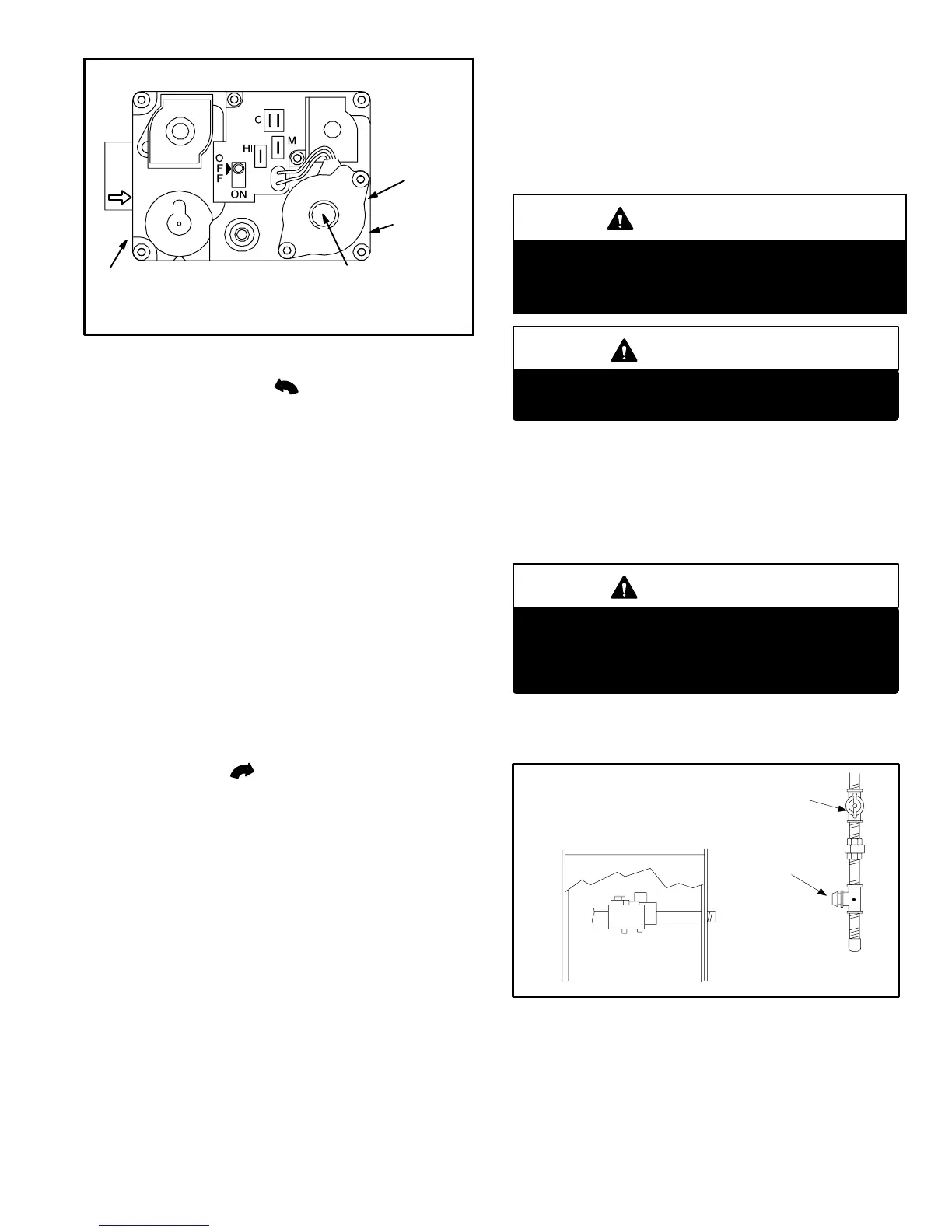

C−Testing Gas Piping

IMPORTANT

In case emergency shutdown is required, turn off

the main shut-off valve and disconnect the main

power to unit. These controls should be properly

labeled by the installer.

When pressure testing gas lines, the gas valve must be dis-

connected and isolated. Gas valves can be damaged if

subjected to more than 0.5psig (14" W.C.). See figure 37.

FIGURE 37

MANUAL MAIN SHUT−OFF VALVE

GAS VALVE

CAP

GAS PIPING TEST PROCEDURE

Loading...

Loading...