• 57 •

25 |

26 •

27 •

28 |

29 •

30 •

31 •

32 |

33 |

34 |

35 |

Installation manual /eCOMFORT-MIL150E-0916 / 05/2017

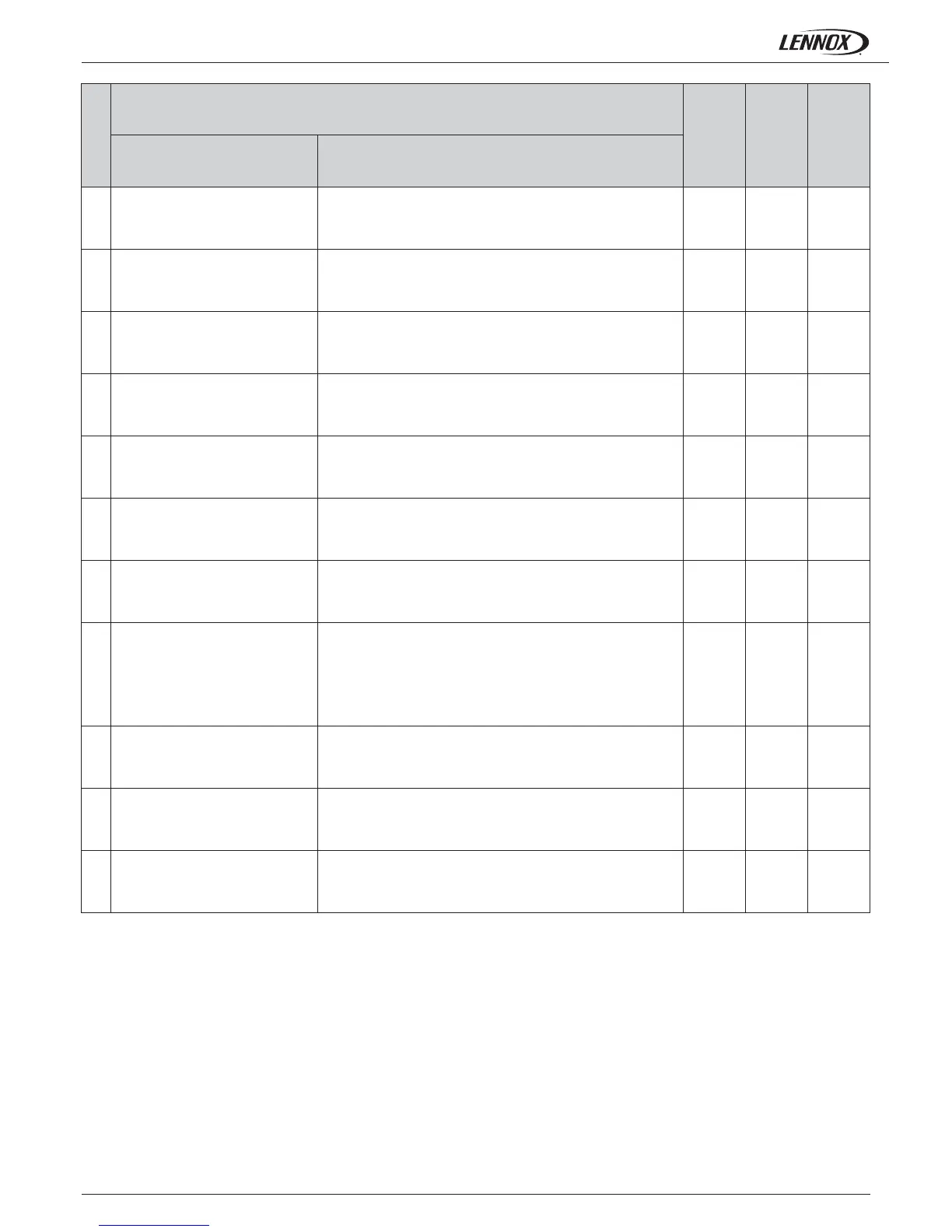

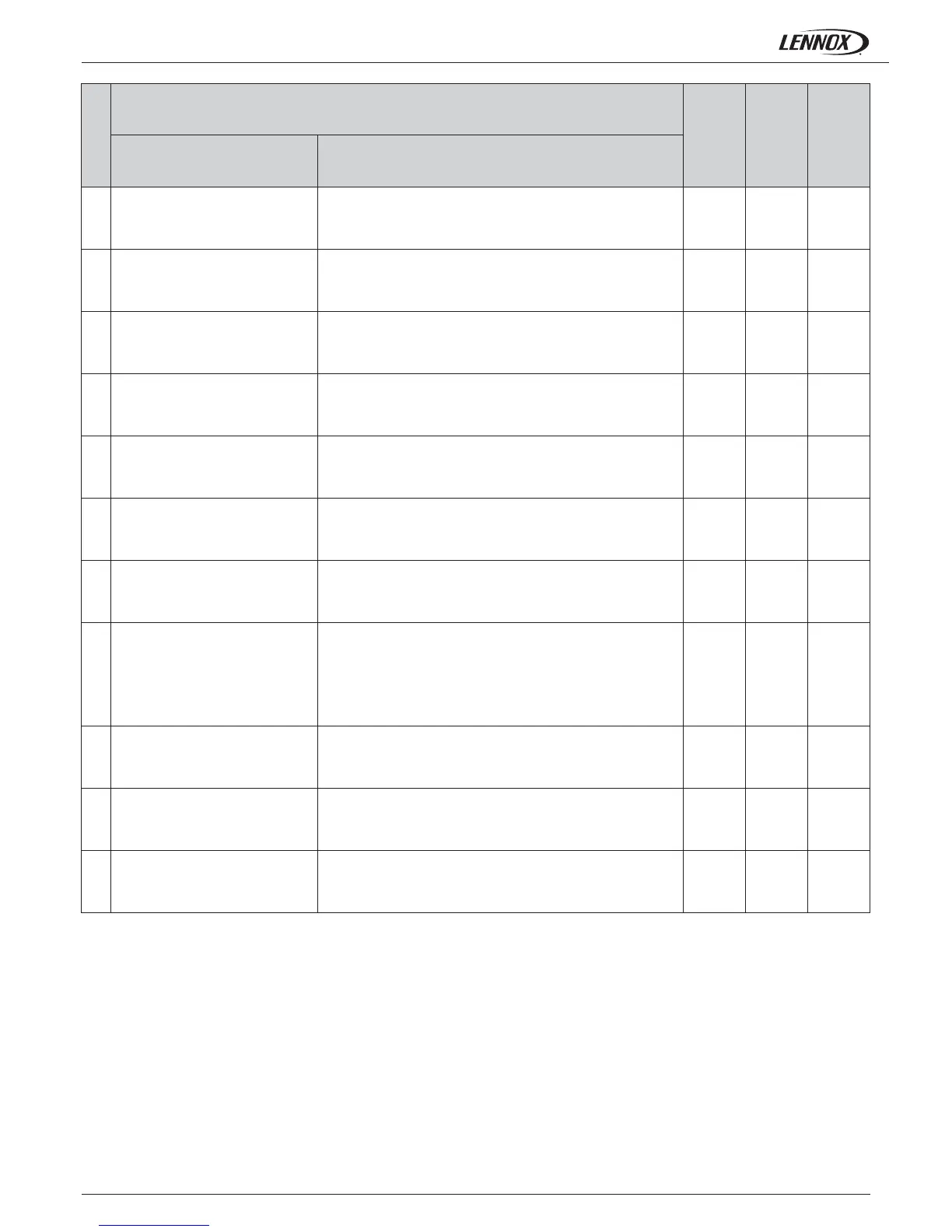

N°

MAINTENANCE PLAN

Monthly

+ Quarterly

Half Yearly

Task Operating mode

Check the value of the analogue

sensors

Install the pressure gauge calibrated to check the analogue sensors .

Install a thermometer calibrated to control the sensors.

Check the position of all sensors Check the good positioning and the fi xation of all sensors.

Check anti-vibration mountings, for

wear and tear.

Visually check anti-vibration mountings on compressors and centrifu-

gal fan. Replace if damaged.

Check Glycol concentration in the wa-

ter circuit

Check the glycol concentration in the pressurized water circuit. (a

concentration of 30% gives a protection down to approx.. -15°C)

Check the circuit pressure

Check casing and equipment

corrosion

To treat and neutralize eventuals rust spots

Check the watertightness of the unit

and it’s accessories

Verify the gaskets, if cracked or ripped, repair them or replace them.

Check the watertightness of the water

circuit

Check for water leaks and repair if it’s needed.

Check the water pump

When the installation is going to work with percentages of glycol

up to 20% and water temperatures below -5ºC, even do we use a

specifi c closing for the water pump, it is advisable to clean the wa-

ter pump’s closing every year and a half, in order to avoid leaks by

crystallization.

Plate exchanger

Prove the general isolation state and tightness of the water connec-

tion and the freeze protection.

Check the expansion vessel if

appropriate

Measure the pressure under the different water modes ( from +7°C

to +45°C)

Check the software version Contact the manufacturer for updates

Loading...

Loading...