• 58 •

Installation manual /eCOMFORT-MIL150E-0916 / 05/2017

4 3- CLEANING THE CONDENSER

4.3.1 - Air cooled condensers

Clean the coils either with a vacuum cleaner, cold water, compressed air, or with a soft brush (non metallic). On units installed in a

corrosive aosphere, coil cleaning should be part of the regular maintenance program. On this type of installation, all dust gathered on

the coils should be quickly removed by regular cleaning.

Caution: Except for NEOSYS range with MCHx coils, do not use high pressure cleaners that could cause permanent damage to the

aluminium coil fi ns.

For microchannel heat excahngers, the coil connexion to the circuit is made by means of a solder copper /

aluminum. This connection is protected from galvanic corrosion by a special resin encapsulated in a heats-

hrinkable sheath.

This sleeve must be regularly visually inspected during unit cleaning operations to detect a possible prema-

ture deterioration.

Specifi c maintenance of microchannels exchangers connection

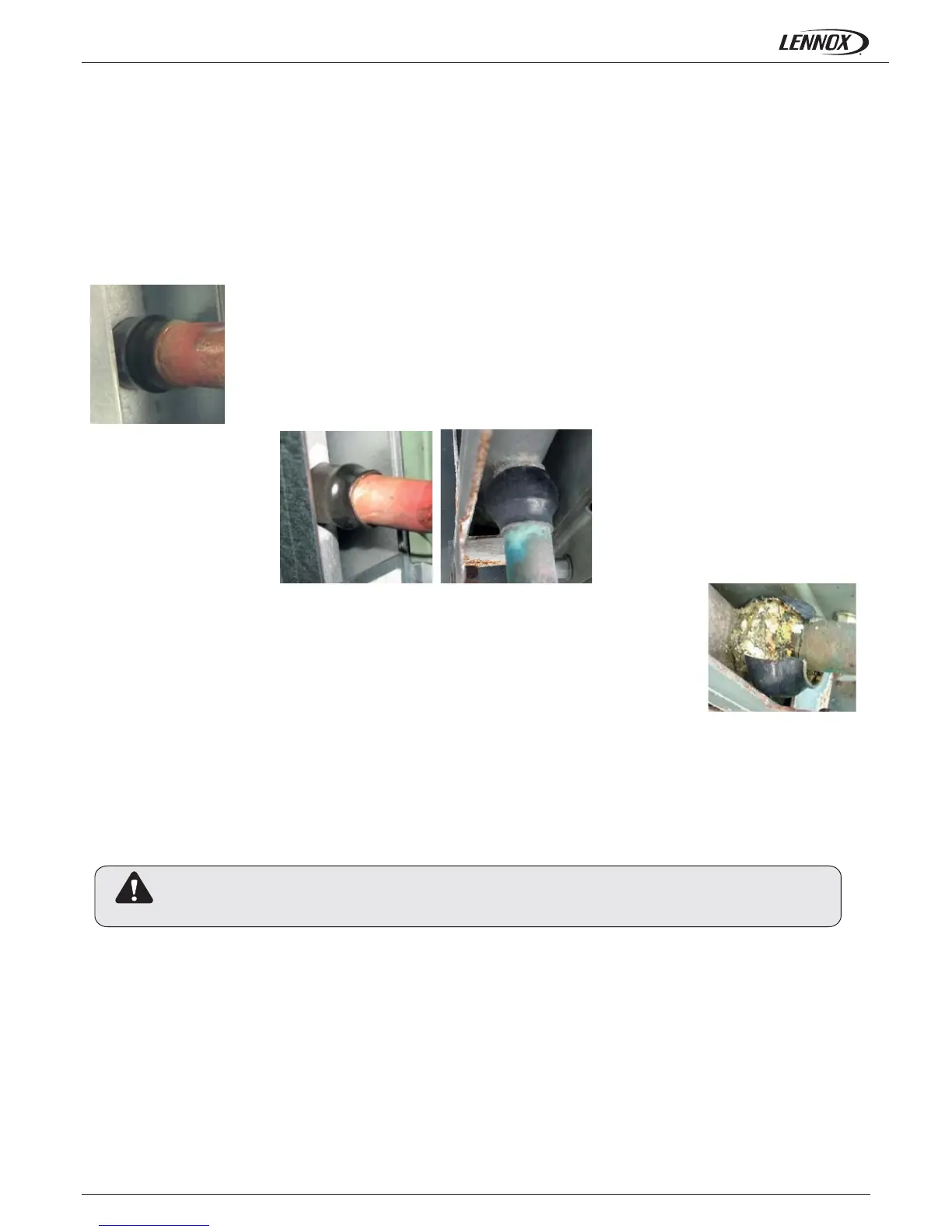

Bad shapeGood shape

Indeed with slightly corrosive aospheres, a small copper etching can lead to a loss of adhesion of

the resin thus allowing moisture to seep under the sleeve while triggering galvanic corrosion pheno-

mena between the aluminum and the Copper.

If this attack is not detected in time, a leak may appear and then force change of the exchanger.

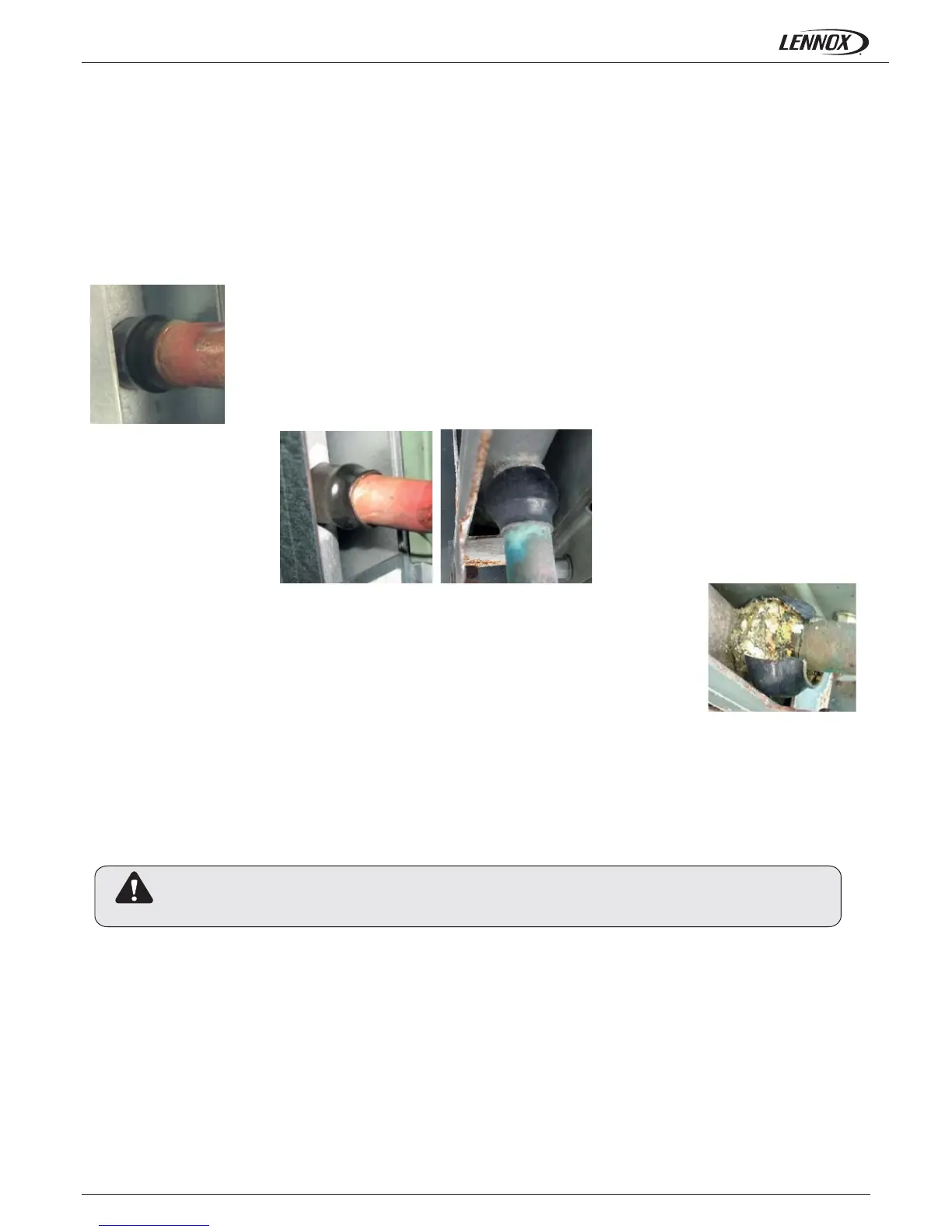

Galvanic corrosion under

the plastic sleeve.

A LEAKAGE BY CORROSION DUE TO A LACK OF CONDENSER MAINTENANCE IS

NOT COVERED BY UNIT WARRANTY

In case of deterioration of the sleeve, it must be removed and replaced by polyurethane sealant - like Sikafl ex 221 or equivalent.

In this case the recommended procedure is as follows :

4.- MAINTENANCE

Loading...

Loading...