• 60 •

Installation manual /eCOMFORT-MIL150E-0916 / 05/2017

4.5.- CORRECTIVE MAINTENANCE

IIMPORTANT MAKE SURE THAT THE UNIT IS COMPLETELY DISCONNECTED FROM THE POWER SUPPLY WHEN

CARRYING OUT ANY TYPE OF WORK ON THE MACHINE

If some component in the cooling circuit must be replaced, follow these recommendations:

- Always use original replacement parts.

- Regulation prohibits the release on the refrigerant into the aosphere.

- If cuts must be made in the pipe work, use pipe cutters. Do not use saws or any other tools that produce fi lings.

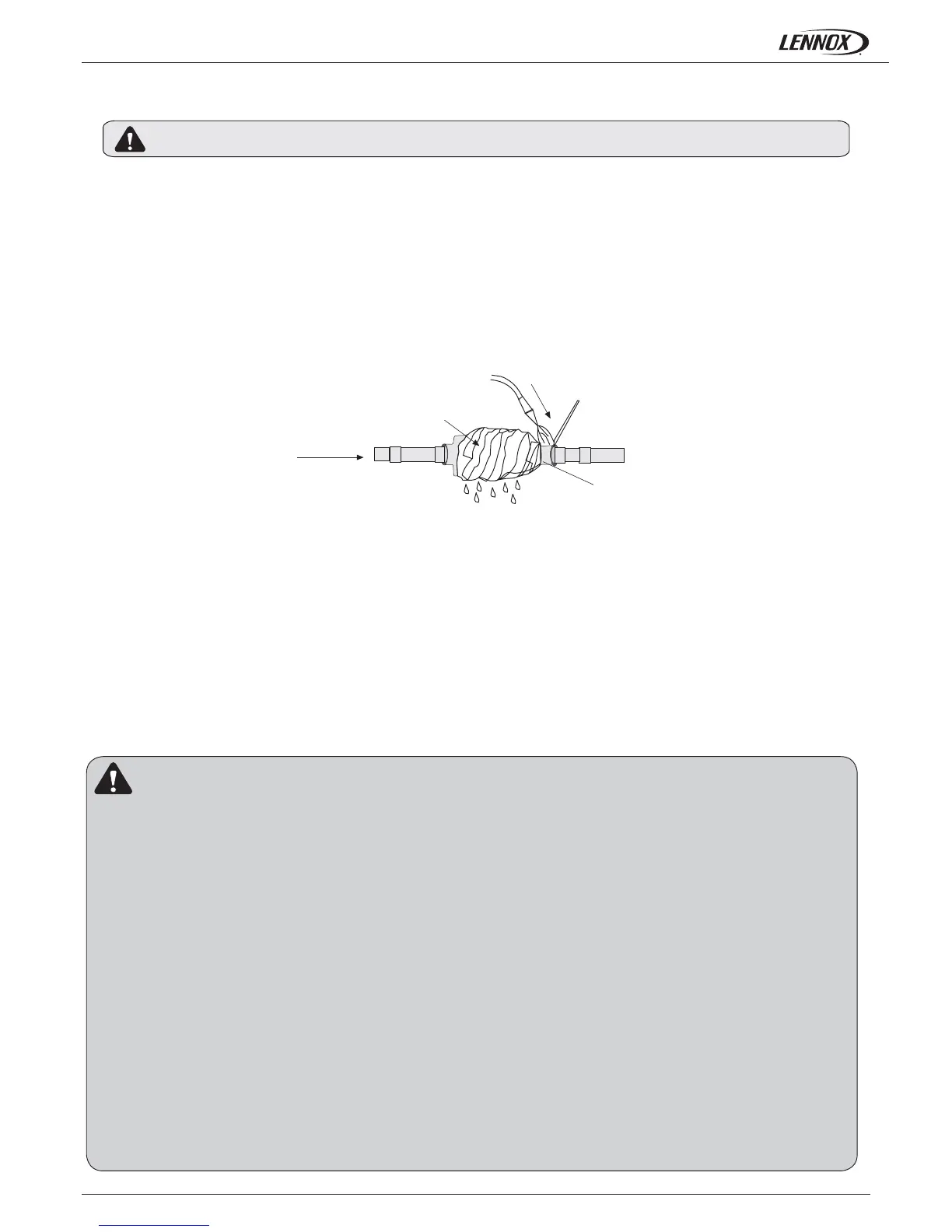

- All brazing must be carried out in a nitrogen aosphere to prevent corrosion from forming.

- Use silver alloy brazing rod.

- Take special care that the fl ame from the torch is aimed in the opposite direction from the component to be welded and is

covered with a wet rag in order to avoid overheating.

Component to be welded

Nitrógen

Wet rag

Direction of the fl ame

Silver alloy welding rod

- Take very special care if 4-way check valves are to be replaced since these have internal components that are very heat-sensitive

such as plastic, tefl on, etc.

- If a compressor must be replaced, disconnect it electrically and un-braze the suction and discharge lines. Remove the securing

screws and replace the old compressor with the new one. Check that the new compressor has the correct oil charge, screw it to the

base and connect the lines and electrical connections.

- Carry out the vacuum above and below through the Schrader valves of the outdoor unit until -750 mm Hg is reached.

Once this level of vacuum has been reached, keep the pump in operation for at least one hour. DO NOT USE THE COMPRESSOR

AS A VACUUM PUMP. If the compressor runs in vacuum it will fail.

- Charge the unit with refrigerant according to the data on the Rating Plate for the unit and check that there are no leaks.

PRECAUTIONS TO BE TAKEN IN THE USE OF R-410A REFRIGERANT

The following precautions characteristic of this gas should be taken:

- The Vacuum Pump must have a Check Valve or Solenoid Valve.

- Pressure Gauges and Hoses for the exclusive use with R-410A Refrigerant should be used.

- The charge should be carried out in the Liquid Phase.

- Always use scales to weight-in charge

- Use the Leak Detector exclusive for R-410AC Refrigerant.

- Do not use mineral oil, only synthetic oil to ream, expand or make connections.

- Keep pipes capped before using them and be very thorough about any possible moisture and dirt (dust, fi lings, burrs, etc.).

- Brazing should always be carried out in a nitrogen aosphere.

- Reamers should always be well sharpened.

- The refrigerant bottle must contain at least 2 % of the total amount.

- All the components derived from the recycling of the unit should be managed according local legislation, and have to be

classifi ed and separated while dealt by authorized waste manager or be left in local waste facilities.

- Refrigerant fl uids, electronic boards, heat exchangers and the oil extracted from the refrigerant circuit, as well as the oil

recipients used must be recycled as hazardous waste according the local normative through an authorized waste manager

or be left in local waste facilities. The rest of the components considered as non-hazardous wastes must be recycled

according to the corresponding norms.

- At the end of its life, the equipment should be recycled in local waste facilities or by an authorized waste manager.

4.- MAINTENANCE

Loading...

Loading...