32

240012994 Rev. B [08/31/2020]

CAUTION

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the re

department.

!!

7 - GAS SUPPLY PIPING

DANGER

Fire Hazard. Do not use matches, candles, open

ames, or other methods providing ignition source.

Failure to comply will result in death or serious injury.

!

WARNING

If overheating occurs or gas supply fails to shut o, do

not turn o or disconnect the electrical supply to the

pump. Shut o gas supply at a location external to the

appliance.

Do not use this boiler if any part has been under water.

Call a qualied service technician before use.

!

WARNING

Fire, explosion, asphyxiation and burn hazard. Boiler

piping and gas connections shall be leak tested before

placing boiler in operation. Failure to follow these

instructions and or improper installation could result in

death or serious injury.

!

NOTICE

Use of CSA approved corrugated, semi-rigid stainless

steel tubing with polyethylene jacketing is approved

for use with boilers following tubing manufacturer's

instructions.

Use of exible "appliance whip" gas tubing is not

allowed per NFPA 54.

NOTICE

If overheating occurs or gas supply fails to shut o, do

not turn o or disconnect electrical supply to pump.

Shut o gas supply at location external to the boiler.

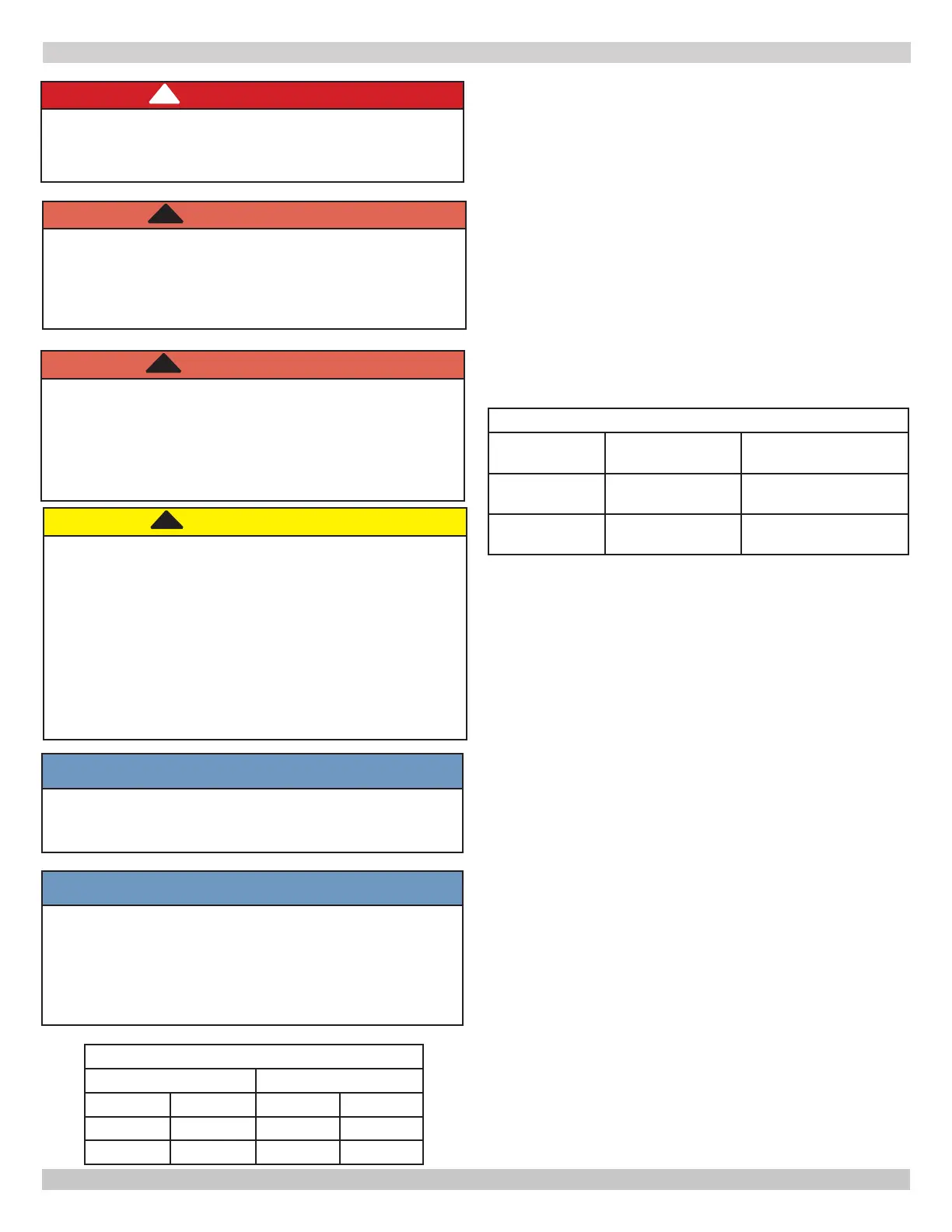

REQUIRED GAS SUPPLY PRESSURE

NATURAL GAS LIQUID PROPANE

Min. Max. Min. Max.

3.5" w.c. 10.5" w.c. 8.0" w.c. 13.0" w.c.

(0.7 kPa) 2.61 (kPa) 1.99 (kPa) 3.23 (kPa)

7.1 General

• Use piping materials and joining methods acceptable

to authority having jurisdiction. In absence of such

requirements:

• USA - National Fuel Gas Code, ANSI Z223.1/NFPA 54

• Canada - Natural Gas and Propane Installation Code,

CAN/CSA B149.1

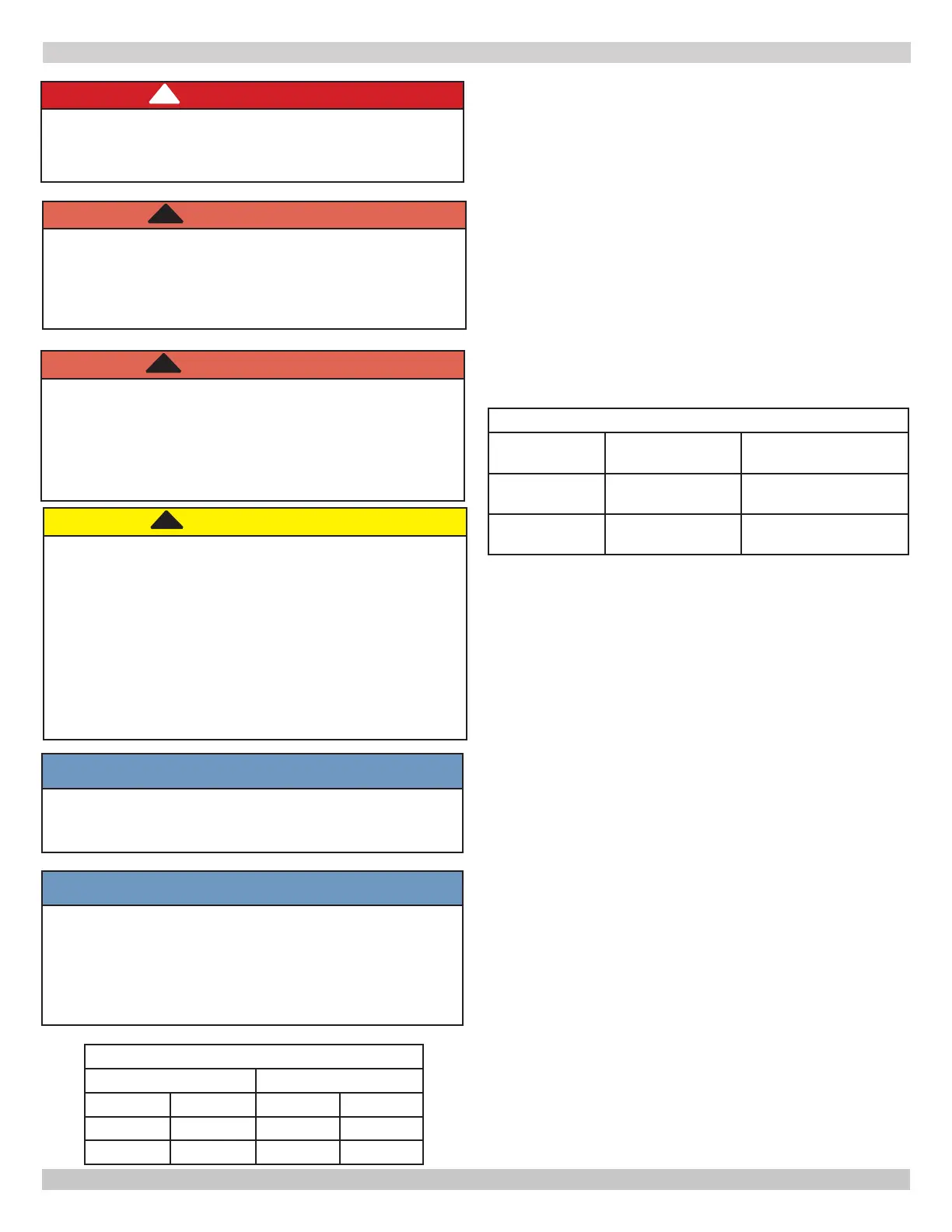

GAS SUPPLY REQUIRED:

MODEL

NATURAL GAS

(A)

LIQUID PROPANE

(E)

GCWB95W-150

143 ft3/h

(4.00 m

3/h)

61.15 ft

3/h

(1.72 m

3/h)

GCWB95W-205

191 ft3/h

(5.40 m

3/h)

82 ft

3/h

(2.30 m

3/h)

• Boiler shall be isolated from the gas supply piping system

by closing its individual manual shuto valve during

any pressure testing of gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

• Install boiler so that gas ignition system components are

protected from water (dripping, spraying,rain, etc.) during

appliance operation and service (circulator replacement,

condensate trap, control replacement, etc.).

• Gas meter and supply pipes must be capable of delivering

the listed quantity of gas in addition to demand from any

other appliances in the house. Boiler requires a 3/4” (19.5

mm) gas supply pipe.

• Support piping with hooks straps, bands, brackets,

hangers, or building structure components to prevent or

dampen excessive vibrations and prevent strain on gas

connection. Boiler will not support piping weight.

• Use thread (joint) compound (pipe dope) suitable for

liqueed petroleum gas.

• Install external eld sourced manual main gas shuto

valve, ground joint union, and sediment trap upstream of

gas controls.

• Install boiler so gas ignition system components are

protected from water dripping, spraying,rain, etc. During

appliance operation and service.

• Leak test boiler and gas line connections before placing

boiler into operation.

• Install manual main shuto valve before the gas valve

accordance with state and local requirements.

• Size and install gas piping system to provide sucient gas

supply to meet maximum input at not less than minimum

supply pressure.

• Boiler and its individual shuto valve shall be disconnected

from gas supply piping system during any pressure testing

of that system at test pressures in excess of 1/2 psi (3.40

kPa - 34.47 mbar).

Loading...

Loading...