Page 16

LGT/LCT156, 180, 210, 240, 300

D-Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are maintained.

Tension new belts after a 24-48 hour period of operation.

This will allow belt to stretch and seat into pulley grooves.

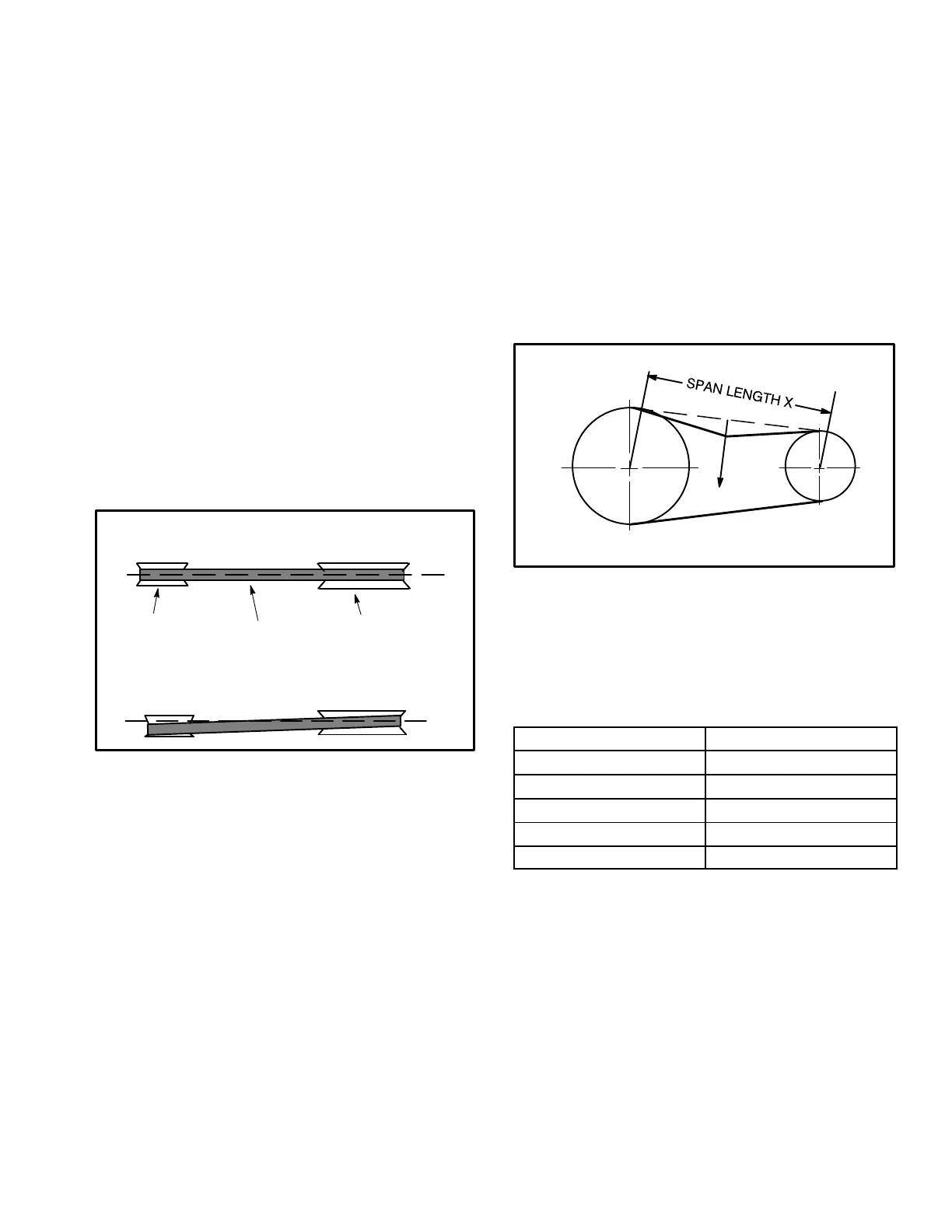

Make sure blower and motor pulley are aligned. See figure

16.

1- Loosen four screws securing blower motor to sliding

base. See figure 15.

2- To increase belt tension -

Turn belt tension adjusting screw to the left, or

counterclockwise, to tighten the belt. This increases

the distance between the blower motor and the

blower housing.

To loosen belt tension -

Turn the adjusting screw to the right, or clockwise to

loosen belt tension.

3- Tighten four screws securing blower motor to sliding

base once adjustments have been made.

FIGURE 16

PULLEY ALIGNMENT

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

E-Check Belt Tension

Overtensioning belts shortens belt and bearing life.

Check belt tension as follows:

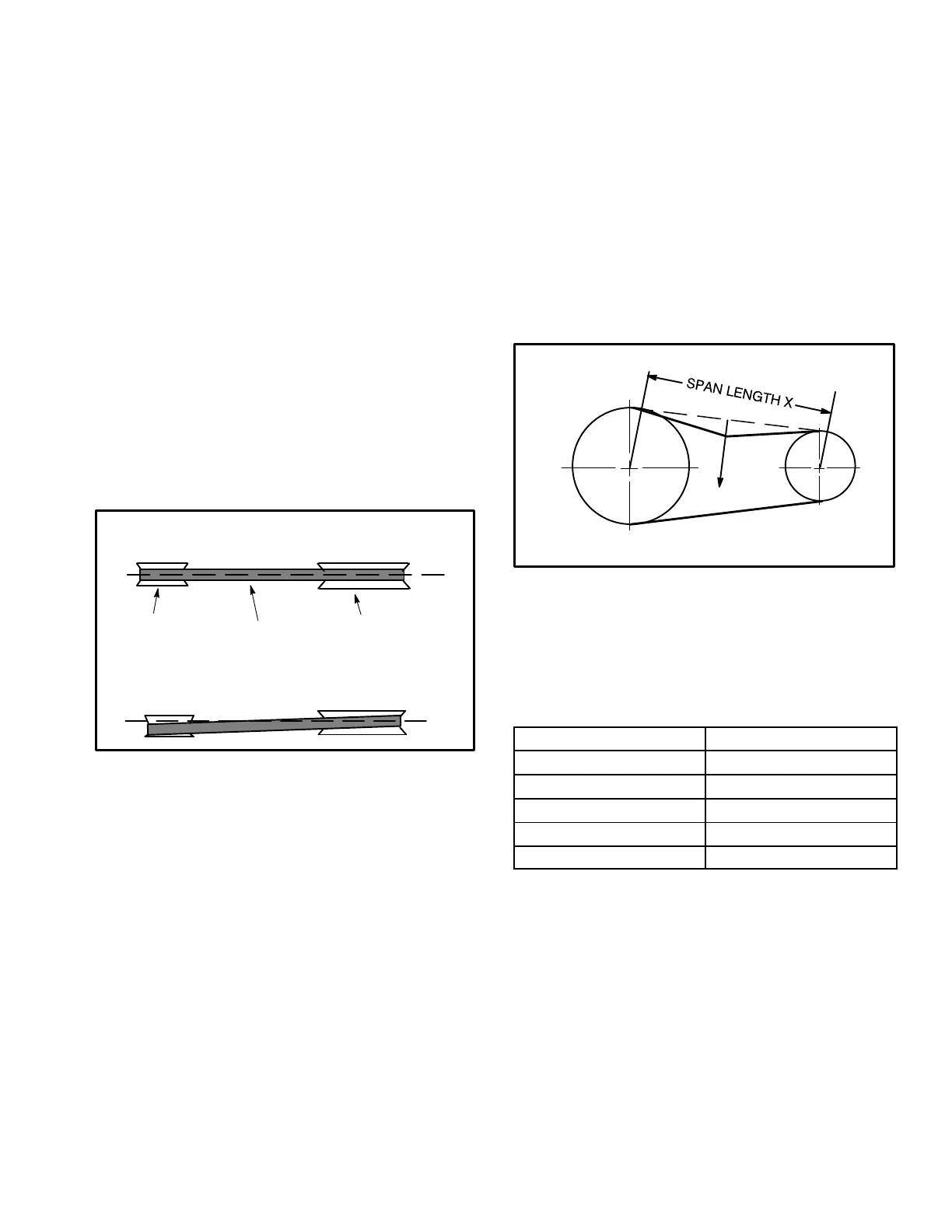

1- Measure span length X. See figure 17.

2- Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch

of span length or 1.5mm per 100mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 400mm span

would be 6mm.

3- Measure belt deflection force. For a used belt, the

deflection force should be 5 lbs. (35kPa) . A new belt

deflection force should be 7 lbs. (48kPa).

A force below these values indicates and

undertensioned belt. A force above these values

indicates an overtensioned belt.

MEASURE BELT TENSION

FIGURE 17

DEFLECTION 1/64” PER INCH OF SPAN

OR 1.5mm PER 100mm OF SPAN

FORCE

F-Field-Furnished Blower Drives

For field-furnished blower drives, use page 16 to

determine BHP and RPM required. Reference page 17 to

determine the manufacturer's model number.

G-Minimum Airflow For Optional Electric Heat

Electric Heat kW Minimum CFM

15 5200

30 5200

45 5200

60 5200

90 6000

Loading...

Loading...