Page 20

LGH/LCH420, 480, 540, 600

B-Check Belt Tension

Overtensioning belts shortens belt and bearing life. Check

belt tension as follows:

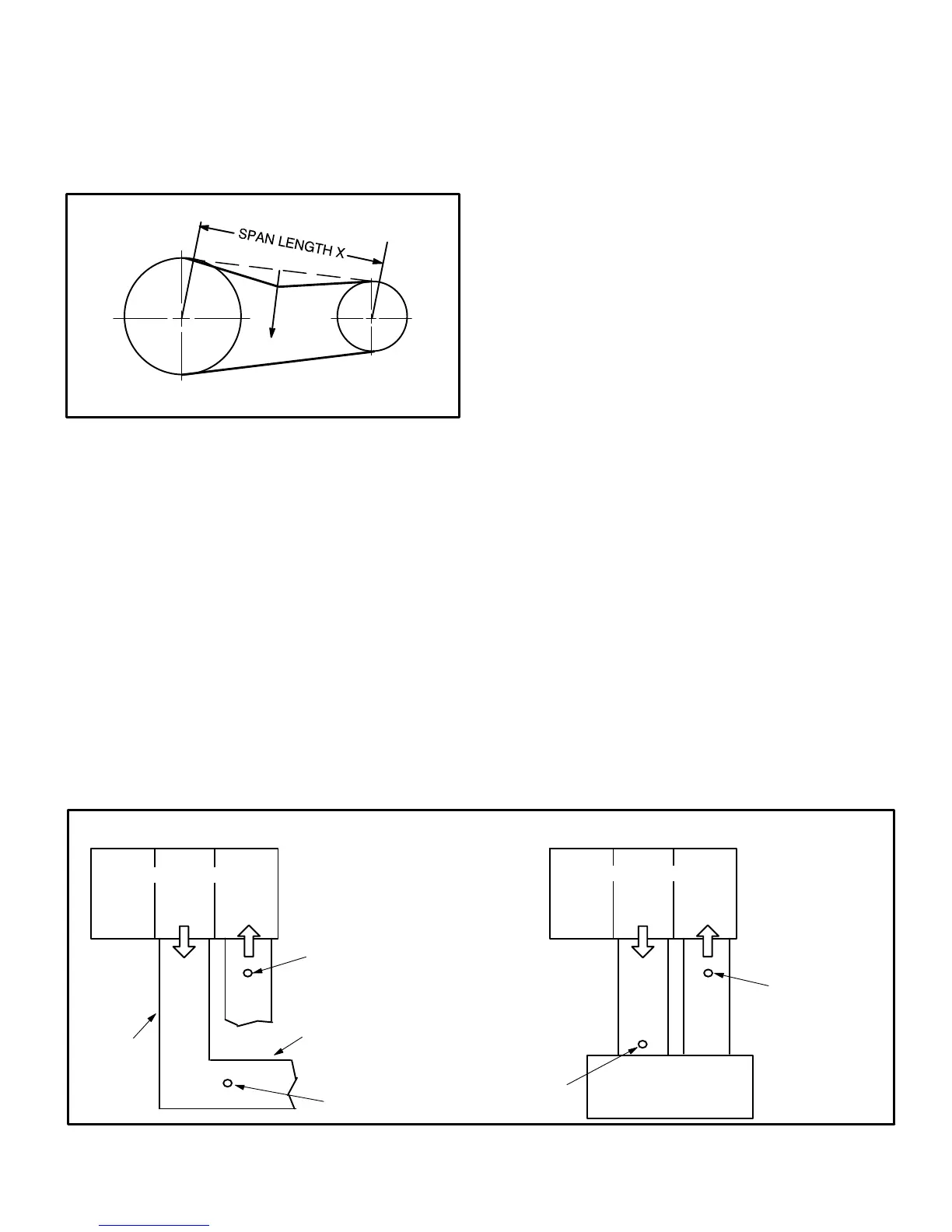

1-Measure span length X. See figure 28.

MEASURE BELT TENSION

FIGURE 28

DEFLECTION 1/64” PER INCH OF SPAN

OR 0.4mm PER 25.4mm OF SPAN

FORCE

2-Apply perpendicular force to center of span (X) with

enough pressure to deflect belt 1/64” for every inch of

span length or 0.4mm per 25.4mm of span length.

Example: Deflection distance of a 40” span would be

40/64” or 5/8”.

Example: Deflection distance of a 1016mm span would

be 16mm.

3-Measure belt deflection force. Used belt values apply

when tightening the belt after 24-48 hours.

For a used belt, the deflection force should be:

5 lbs. for 5 & 7.5 HP applications

8 lbs. for 10 & 15 HP applications

7 lbs. for 20, 25, & 30 HP applications

For a new belt, the deflection force should be:

8 lbs. for 5 & 7.5 HP applications

12 lbs. for 10 & 15 HP applications

11 lbs. for 20, 25, & 30 HP applications

A force below these values indicates an

undertensioned belt. A force above these values

indicates an overtensioned belt.

C-Blower Operation

Initiate blower only (G) demand at thermostat according to

instructions provided with thermostat. Unit will cycle on

thermostat demand. The following steps apply to

applications using a typical electro-mechanical thermostat.

1- Blower operation is manually set at the thermostat

subbase fan switch. With fan switch in ON position,

blowers will operate continuously.

2- With fan switch in AUTO position, the blowers will cycle

with demand. Blowers and entire unit will be off when

system switch is in OFF position.

C-Determining Unit CFM

1- The following measurements must be made with a dry

indoor coil. Run blower (G demand) without a cooling

demand. Measure the indoor blower shaft RPM. Air

filters must be in place when measurements are taken.

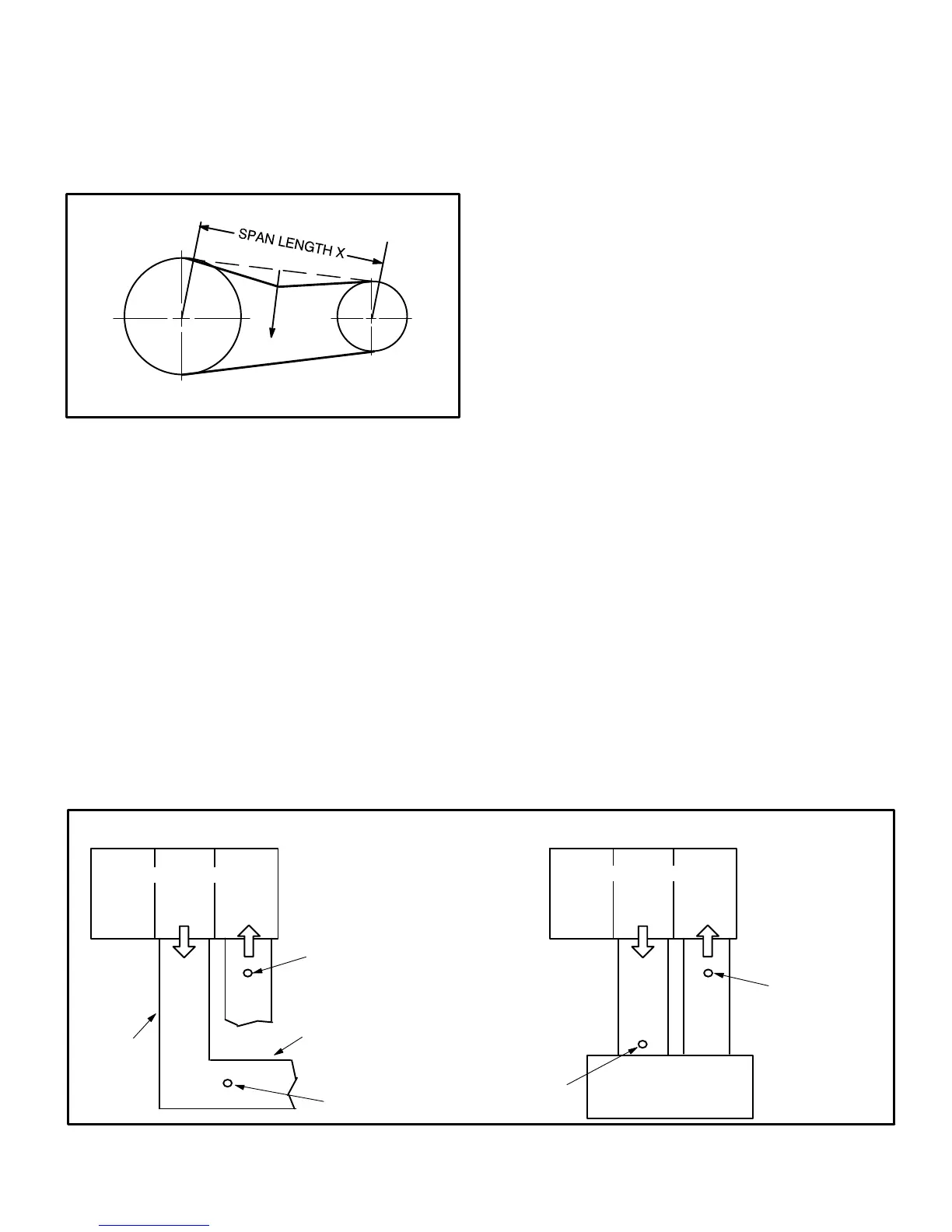

2- With all access panels in place, measure static

pressure external to unit (from supply to return). Blower

performance data is based on static pressure readings

taken in locations shown in figure 29.

3- With all access panels in place, measure static

pressure external to unit (from supply to return). Blower

performance data is based on static pressure readings

taken in locations shown in figure 29.

Note - Static pressure readings can vary if not taken where

shown.

FIGURE 29

LOCATION OF STATIC PRESSURE READINGS

SUPPLY AIR

READING

LOCATION

SUPPLY

RE

TURN

INSTALLATIONS WITH DUCTWORK

SUPPLY

RE

TURN

INSTALLATIONS WITH CEILING DIFFUSERS

MAIN

DUCT RUN

FIRST BRANCH

OFF OF MAIN RUN

DIFFUSER

ROOFTOP UNIT

ROOFTOP UNIT

SUPPLY AIR

READING

LOCATION

RETURN AIR

READING LOCATION

RETURN AIR

READING

LOCATION

Loading...

Loading...