Page 21

507232-04 7/2017

4- Referring to Page 22 and Page 23, use static pressure

and RPM readings to determine unit CFM. Use

Page 28 when installing the unit in horizontal air

discharge applications. Use Page 29 when installing

units with any of the optional accessories listed.

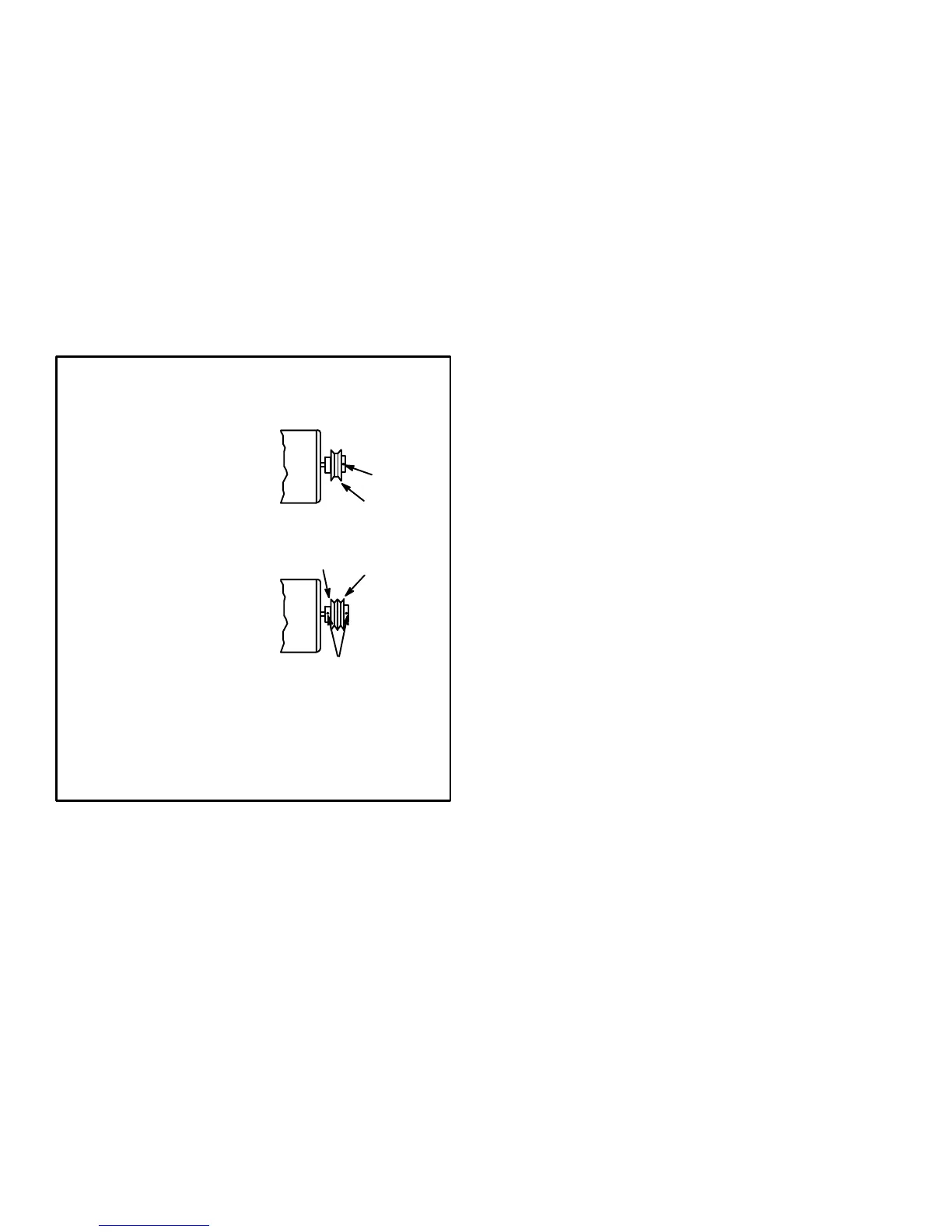

5- The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley clockwise

to increase CFM. Turn counterclockwise to decrease

CFM. See figure 30 and 25.

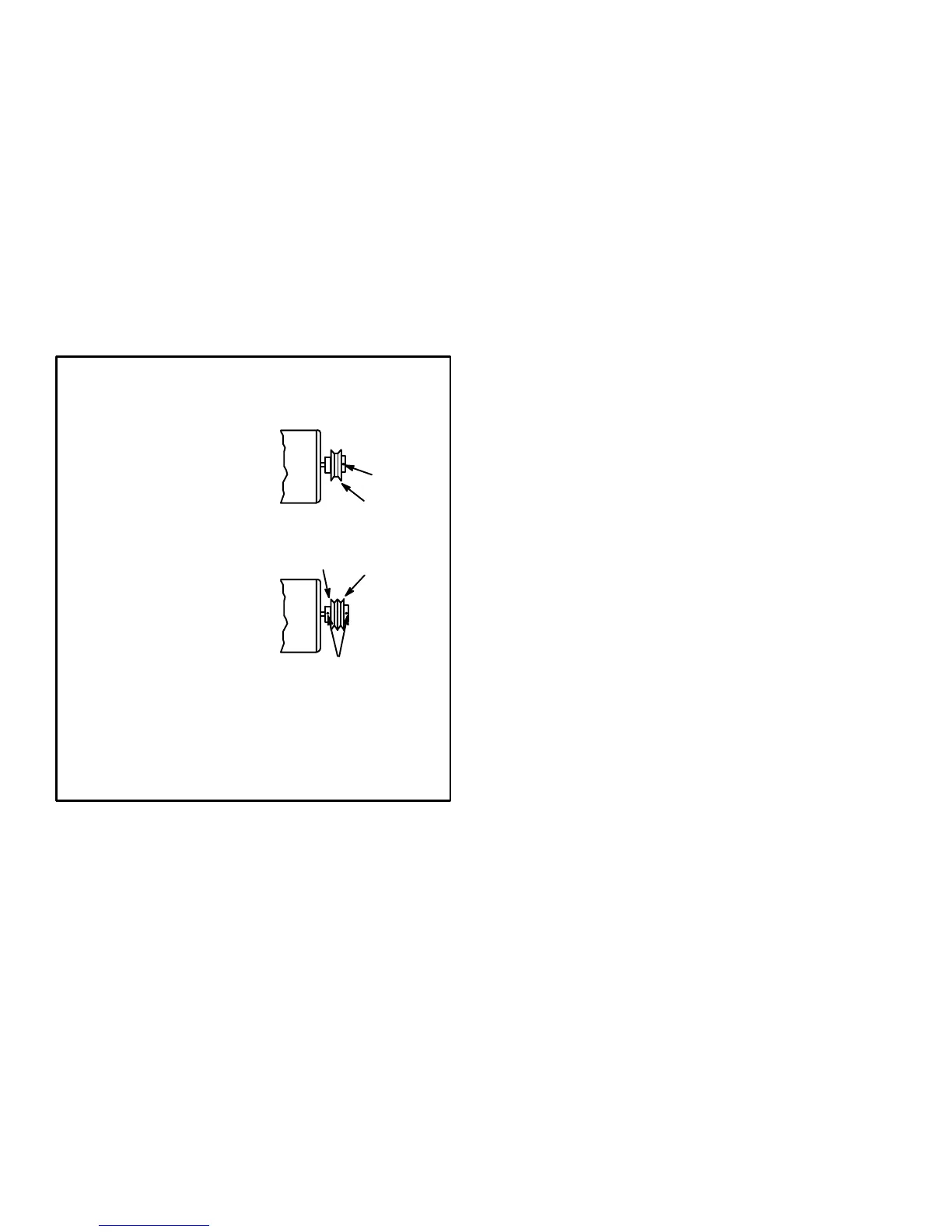

Loosen both Allen screws on units equipped with two

belts. Remove the key and turn the inner sheave the

opposite direction of the outer sheave. Replace the key

before securing Allen screws.

PULLEY ADJUSTMENT

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

PULLEY

MOTOR

ALLEN

SCREW

SIDE VIEW

FIGURE 30

Note - Pulley minimum number of turns open:1.

Maximum number of turns open: 6.

OUTER SHEAVE

MOTOR

ALLEN

SCREWS

INNER SHEAVE

UNITS EQUIPPED WITH TWO BELTS:

LOOSEN BOTH ALLEN SCREWS AND REMOVE

KEY. TURN INNER SHEAVE THE OPPOSITE DI

RECTION OF THE OUTER SHEAVE. REPLACE

KEY BEFORE SECURING ALLEN SCREWS

6-Variable Air Volume Supply Air Blowers -

In addition to adjusting the motor pulley, the supply

CFM can be adjusted at the Unit Controller or by using

optional software. The VFD must be set to 60Hz. Refer

to the Unit Controller manual parameter 390.

In default mode, the Unit Controller is set to drive the

blower to maximum CFM output (100% or 60Hz). To

decrease the CFM, reduce the VAV maximum output

parameter 390. If the CFM needs to be increased

beyond the motor pulley's capacity at 60Hz, refer to the

drive kit options in this manual to see if there may be a

different drive kit available to increase CFM.

The default minimum blower output is 50% (30Hz).

Refer to parameter 27 and 28 to adjust the VAV

minimum output.

E-Optional Power Exhaust Blowers

1-Determine the power exhaust CFM in the same manner

as the supply CFM with one exception: measure the

return duct static pressure instead of total external

pressure. Use Page 24 through Page 27.

2-The RPM can be adjusted at the motor pulley. Loosen

Allen screw and turn adjustable pulley clockwise to

increase CFM. Turn counterclockwise to decrease CFM.

See figure 25.

F-Field-Furnished Blower Drives

For field-furnished blower drives, use Page 22 through

Page 27 to determine BHP and RPM required. Reference

Page 30 for supply air blower and high static power exhaust

fan drive kit specifications. Reference tables 5 and 6 to

determine the manufacturer's model number.

Loading...

Loading...