Page 16

LGH/LCH420, 480, 540, 600

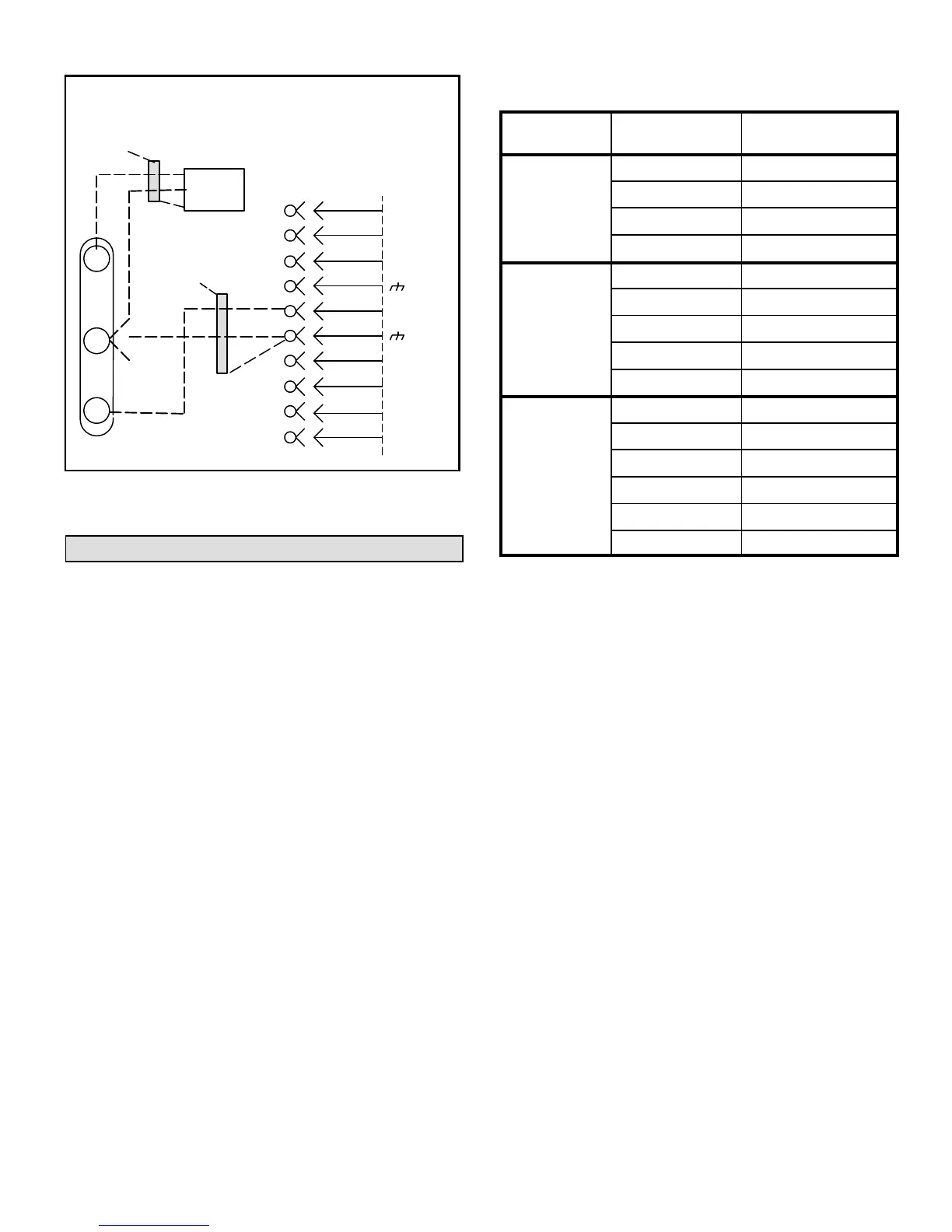

FIGURE 21

FIELD WIRING HOT GAS REHEAT UNITS

(Using A Humidity Sensor With More

Than 150 Ft. Wire Runs)

ISOLATED 24V

TRANSFORMER

9

8

P298

J298A

1

2

B

3

4

C

5

6

7

D

10

A91

VIN

VO

GND

R

C

AI-1

HUM

TMP

DO-1

C

DI-1

DO-2

NOT

CONNECTED

NOT

CONNECTED

DRAIN

A55 UNIT

CONTROLLER

Multi-Staged Air Volume Start-Up

A-Design Specifications

Use table 2 to fill in field-provided, design specified blower

CFM for appropriate unit.

If only high and low cooling design specifications are

provided, set the medium cooling CFM at the high or low

cooling design spec or any CFM between.

B-Set Maximum CFM

Use table 2 to determine highest blower CFM for

appropriate unit. Adjust the blower pulley to deliver that

amount of CFM with only the blower operating. See

Determining Unit CFM in the Blower Operation and

Adjustment section.

C-Set Blower Speeds

1-Use the following menu to enter the blower design

specified CFM into the Unit Controller. Make sure

blower CFM is within limitations shown in table 3. Refer

to the Unit Controller manual provided with unit.

SETUP > TEST & BALANCE > BLOWER >

2-Enter the following design specifications as shown in

table 2.

Blower / Heat CFM

Cooling High CFM

1

Cooling Low CFM

1

Vent CFM

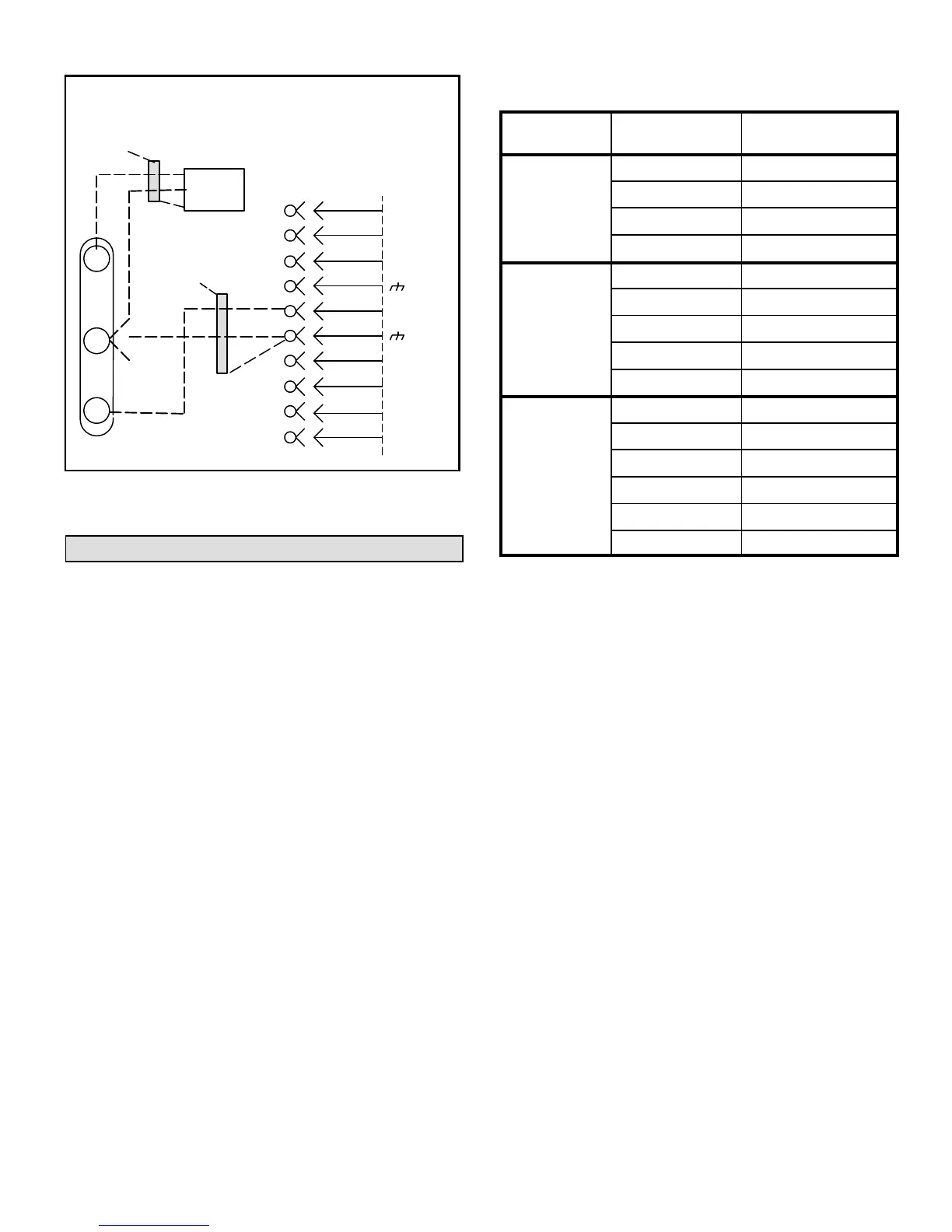

TABLE 2

Blower CFM Design Specifications

No. Stages /

Control Type

Blower Speed

1

Design

Specified CFM

2 Stages /

Thermostat

Htg.

Clg. High

Clg. Low

Ventilation

3 Stages /

Thermostat

2

Htg.

Clg. High

Clg. Med.

Clg. Low

Ventilation

4 Stages /

Room Sensor

OR

Discharge Air

Control

Htg.

Clg. High

Clg. Med. High

Clg. Med. Low

Clg. Low

Ventilation

1

Available blower speeds vary by unit and thermostat stages.

2

Requires a transfer relay (K27) and three-stage thermostat.

3-Adjust the blower RPM to deliver the target CFM based

on the measured static pressure using the blower table.

4-Measure the static pressure again and apply the static

pressure and RPM to the blower tables to determine

adjusted CFM.

5-Repeat adjustments until design CFM is reached.

1

The Unit Controller will prompt when more cooling stages

are available depending on the number of compressors and

the control mode.

2

Requires a transfer relay (K27) and three-stage thermostat.

D-Set Damper Minimum Position

To maintain required minimum ventilation air volumes when

the unit is in the occupied mode, two minimum damper

positions must be set. The Unit Controller will open the

dampers to “Min OCP Blwr Low” when blower CFM is

BELOW a “midpoint” CFM. The Unit Controller will open the

damper to “Min OCP Blwr High” when blower CFM is at or

ABOVE the “midpoint” CFM.

The Unit Controller will calculate the “midpoint” CFM.

Set Minimum Position 1

Use the following menu in the Unit Controller to set “Min

OCP Blwr Low” for the blower CFM below the “midpoint”

CFM. When navigating into this menu, the Unit Controller

will bring on the corresponding blower speed and allow

damper position adjustment.

Loading...

Loading...