Page 29

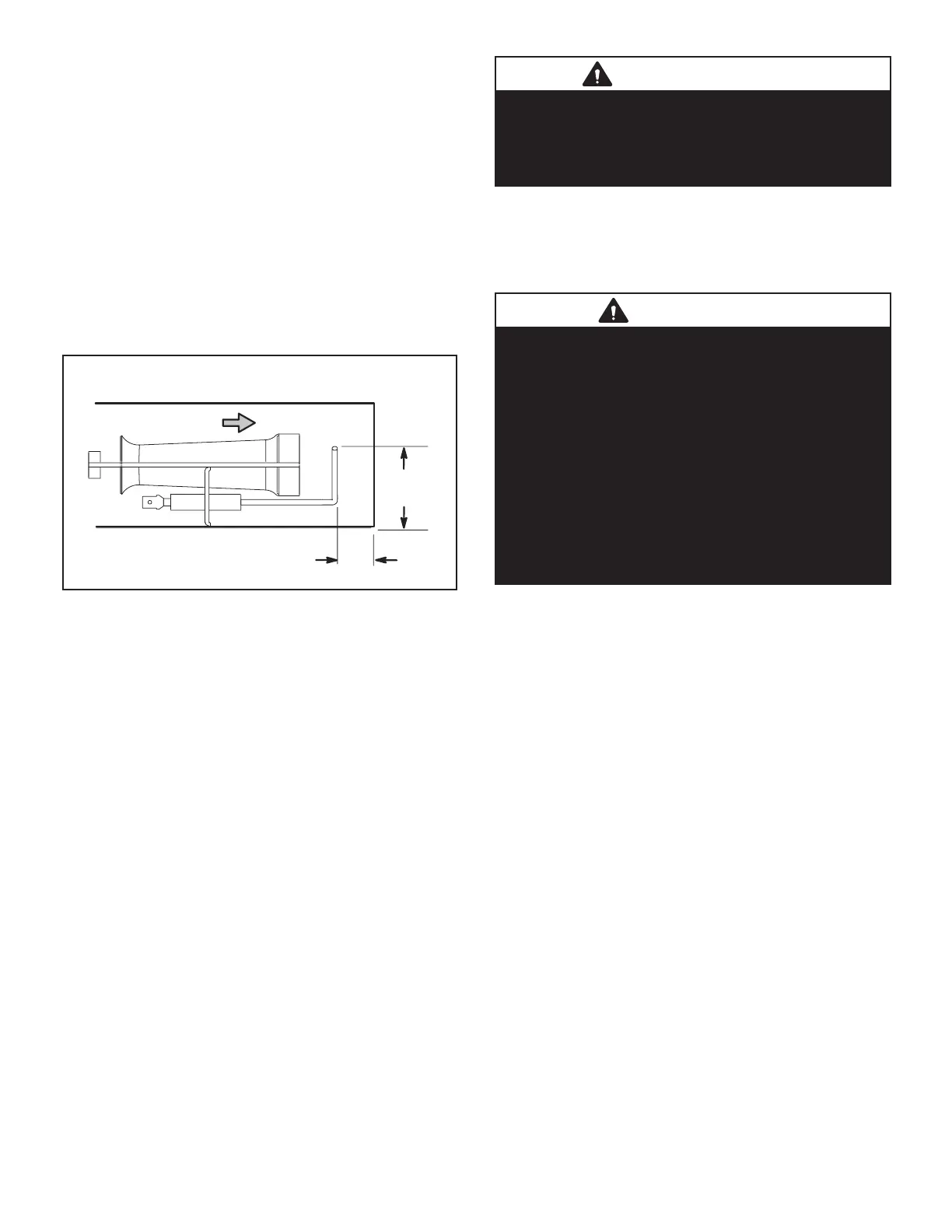

11-Flame Sensor Figure 20

-

sensor assembly is fastened to burner supports and can

be removed for service without removing any part of the

burners.

-

diately or after the eight second trial for ignition. During

ground electrode (located on the spark electrode), through

-

SIDE VIEW SENSOR

1-3/4”

(45mm)

3/8”

(10mm)

Gas Flow

FIGURE 20

D-BLOWER COMPARTMENT

Units are equipped with a variable speed, direct drive

-

cy. The Unit Controller calibrates the supply air volume

which eliminates the need to manually take duct static

measurements.

1-Indoor Blower Motor B3

All direct drive blower motors are electronically commutat-

ed, brushless, DC motors. The motors are powered with

high voltage 3-phase AC power. CFM adjustments are

made by changing Unit Controller parameters via the ser-

vice app. Motors are equipped with sealed ball bearings.

(table of contents) in the front of this manual. Motors come

with pre-mounted aluminum impellers.

IMPORTANT

Three phase scroll compressors must be phased

sequentially for correct compressor and blower

rotation. Follow “COOLING START-UP” section

of installation instructions to ensure proper

compressor and blower operation.

A-Blower Operation

Refer to the Unit Controller Setup Guide to energize blow-

TEST.

WARNING

1-Make sure that unit is installed in accordance with

the installation instructions and applicable codes.

2-Inspect all electrical wiring, both eld-and

factoryinstalled, for loose connections. Tighten as

required.

3-Check to ensure that refrigerant lines do not rub

against the cabinet or against other refrigerant lines.

4-Check voltage at disconnect switch. Voltage

must be within range listed on nameplate. If not,

consult power company and have voltage condition

corrected before starting unit.

5-Make sure lters are new and in place before

startup.

B-Determining Unit CFM

CFM is calculated using a supplied pressure transducer

and can be viewed in the mobile service app. CFM can

also be manually checked as follows:

1 - The following measurements must be made with air

IMPORTANT - A low speed adjustment less than 2/3

of high speed will improve humidity removal; refer to

product data for more information.

2 - With all access panels in place, measure static

pressure external to unit (from supply to return).

Blower performance data is based on static pressure

Note - Static pressure readings can vary if not taken

where shown.

3 - Measure the indoor blower wheel RPM.

4 - Referring to the blower tables in the front of this

manual, use static pressure and RPM readings to

determine unit CFM. Apply the optional accessory

air resistance.

Loading...

Loading...