25

DC-FAN

CN 414

3

AMBIENT TEMP. SENSOR

DISCHARGE TEMP. SENS OR

CN 17

.

Y/G

OUTDOOR

MAIN

PCB

BLUE

BROWN 1

BLACK 3

3

2

L1

L2

RED

BLUE L2

1

Y/G

Y/G

CN 3

Y/G

Y/G

COMPRESSOR

Y/G

U

V

W

BLUE

RED

BLACK

L1

L2

S

CN 6

CN 7

CN 8 CN 2

CN 21

W

V

U

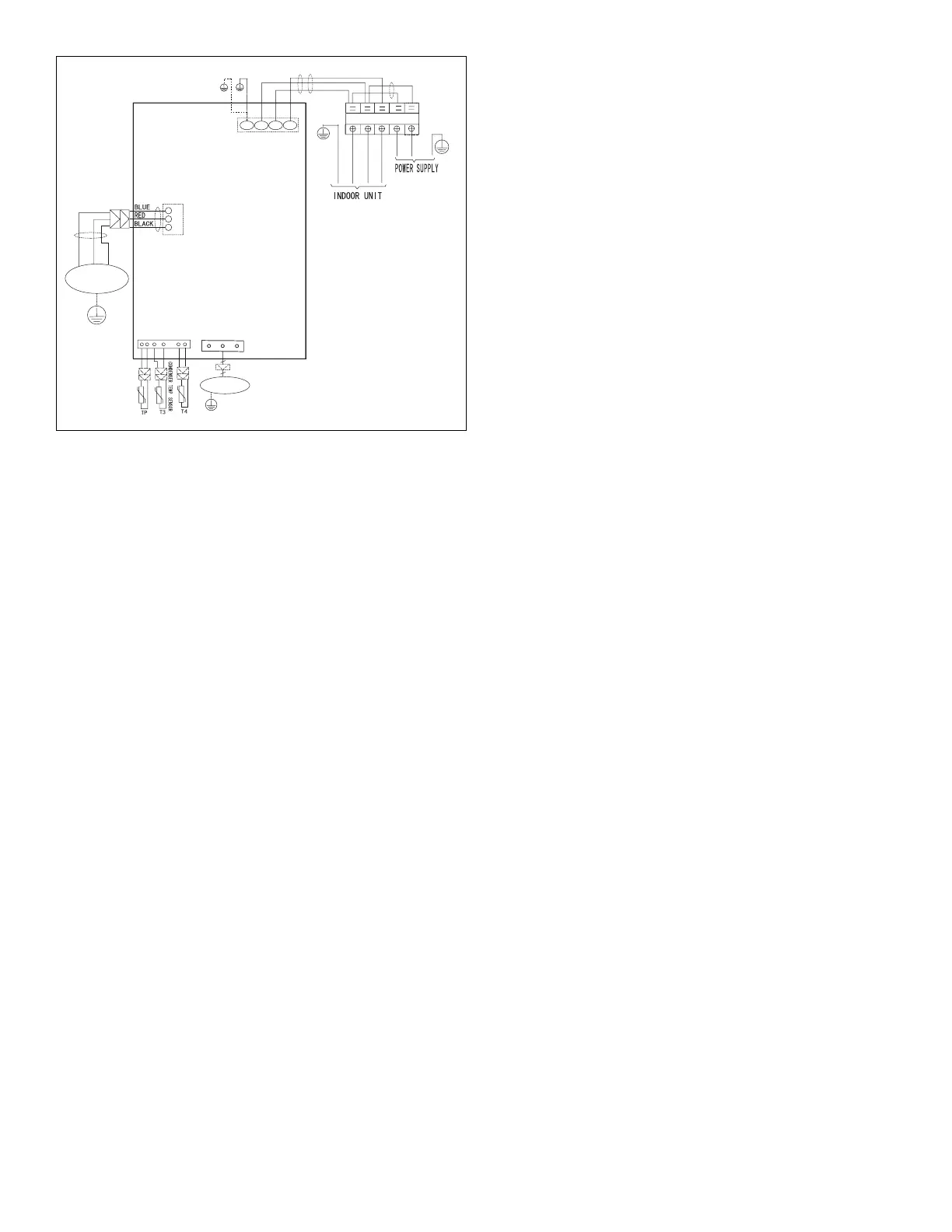

Figure 24. 18K and 24K 208/230VAC Outdoor Unit

Wiring Diagram

13. Installation Requirements

13.1. Gas Leak Check with Soap Water:

Apply soap water or a liquid neutral detergent on the

connectionswithasoftbrushtocheckforleakageinthepipe

connectingpoints.Ifbubblesemerge,thepipesareleaking.

13.2. Air and Moisture

Airandmoistureintherefrigerantsystemcausethefollowing

problems:

• Increasesinsystempressure

• Increasesinoperatingcurrent

• Decreasesincoolingandheatingefciency

• Blocksincapillarytubingcausedbymoistureinthe

refrigerantcircuitfreezing

• Corrosionofpartsintherefrigerantsystemcausedby

water

Theindoorunitsandthepipesbetweenindoorandoutdoor

unitsmustbetestedforleakagesandevacuatedtoremove

gasandmoisturefromthesystem.

13.3. Air Purging using a Vacuum Pump

• Completelytightenthearenutsontheindoorand

outdoorunits.Conrmthatboththetwo-wayandthree-

wayvalvesaresettotheclosedposition.

• Connectthechargehosewiththepushpinofthe

HandleLotothethree-wayvalvegasserviceport.

• ConnectthechargehoseoftheHandleHitothe

vacuumpump.

• FullyopentheHandleLoofthemanifoldvalve.

• Turnonthevacuumpumptobeginevacuation.

• Conducta30-minuteevacuation.Checkwhether

thecompoundmeterindicates-0.1Mpa(14.5Psi).If

themeterdoesnotindicate-0.1Mpa(14.5Psi)after

30minuteshaselapsed,continueevacuationfor20

moreminutes.Ifthepressuredoesnotreach-0.1Mpa

(14.5Psi)after50minuteshaselapsed,checkifthere

areanyleaks.

• FullyclosetheHandleLovalveofthemanifoldvalve

andturnoffthevacuumpump.Afterveminutes,

conrmthatthegaugeneedleisnotmoving.

• Turnthearenutonthethree-wayvalve45°counter-

clockwisefor6-7seconds.Oncegasbeginstocome

out,tightenthearenut.Makesurethepressure

displayonthepressureindicatorishigherthan

atmosphericpressure.Thenremovethechargehose

fromthethree-wayvalve.

• Fullyopenthetwo-wayandthree-wayvalvesand

securelytightenthecaponthethree-wayvalve.

13.4. Adding Refrigerant if Pipe Length

Exceeds Charge Less Pipe Length

Connectthechargehosetothechargingcylinderandopen

the two-way and three-way valves. With the charge hose

youdisconnectedfromthevacuumpump,connectittothe

valveatthebottomofthecylinder.

IftherefrigerantisR-410A,placethecylinderbottom-upto

ensureliquidchargingispossible.

• Purgetheairfromthechargehose.

• Openthevalveatthebottomofthecylinderandpress

thecheckvalveonthechargeset(becarefulofthe

liquidrefrigerant).

• Placethechargingcylinderontotheelectronicscale

andrecordtheweight.

• Turnontheairconditionerincoolingmode.

• Openthevalves(Lowside)onthechargeset.Charge

thesystemwithliquidrefrigerant.

• Whentheelectronicscaledisplaystheproperweight

(refertothetable),disconnectthechargehosefrom

thethree-wayvalve’sserviceportimmediatelyandturn

offtheairconditionerbeforedisconnectingthehose.

• MountthevalvestemcapsandtheserviceportUse

atorquewrenchtotightentheserviceportcaptoa

torqueof18N.m(13.27ft·lbs).

• Besuretocheckforgasleaks.

13.5. Add Refrigerant after Long-Term

System Operation

• Connectthechargehosetothethree-wayserviceport

andopenthetwo-wayandthree-wayvalve.

• Connectthechargehosetothevalveatthebottom

ofthecylinder.IftherefrigerantisR-410A,placethe

cylinderbottom-uptoensureliquidcharge.

Loading...

Loading...