Page 45

High Efficiency Energence A Box Units with Smart Airflow™ (Advance Airflow) Applications that have Smart

Airflow™ option installed and with successful blower calibration, will run the blower at a calculated percent output to

deliver the airflow as set by the installer. The table below shows the default Airflow set points parameter. Parameter

18 by default is 0 but needs to be set to a valid value during installation.

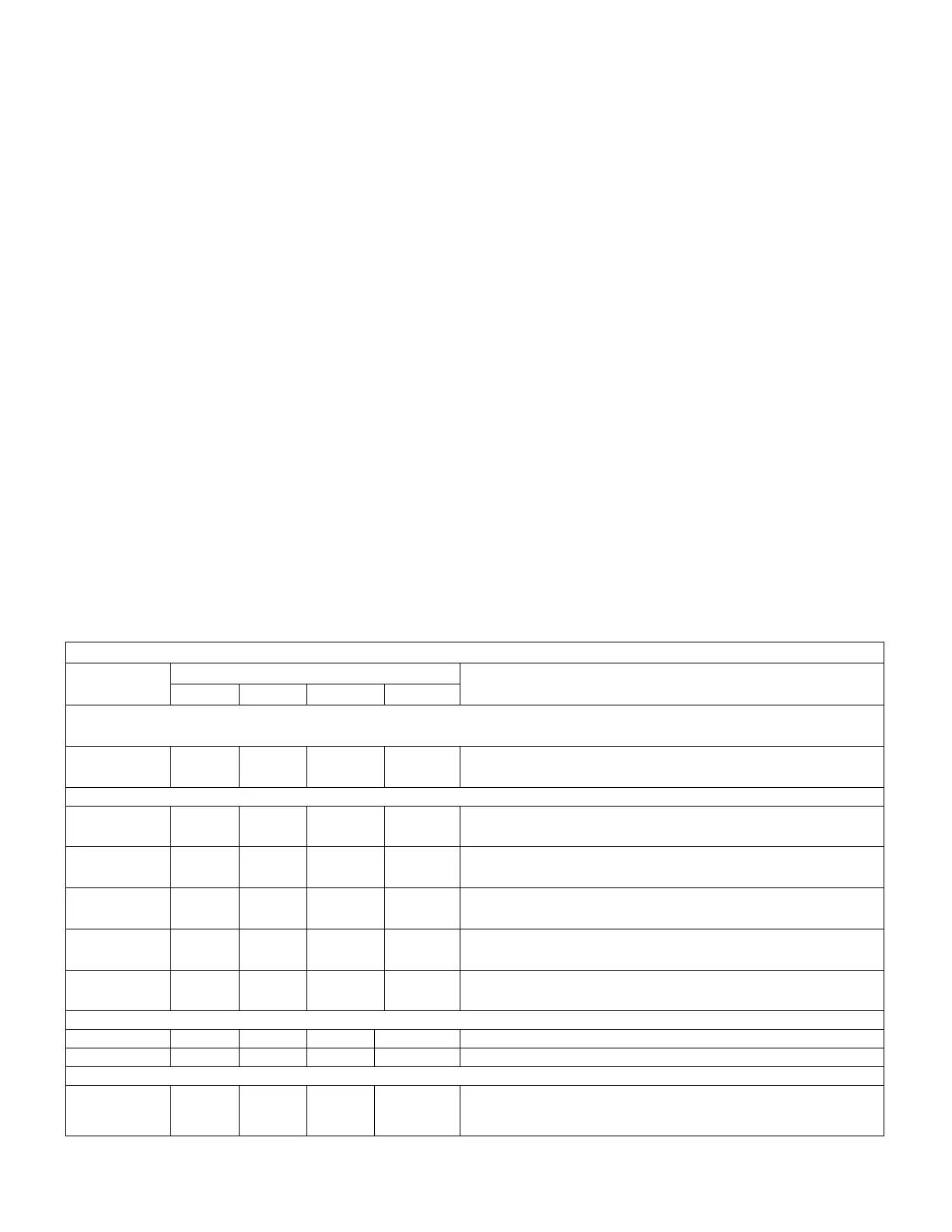

Table 35. High Efficiency Factory Settings (CFM) A Box Smart Airflow™ (3 to 5ton Units)

Operation

3 ton

(in CFM)

4 ton

(in CFM)

5 ton

(in CFM)

Parameter Value

(in CFM/ton)*

Parameter

Value

(in counts)

Parameter

Cooling low, Free cooling low 780 1040 1300 260 130 12

Cooling high, Free cooling high 1080 1440 1800 360 180 14

Heating 1200 1600 2000 400 200 13

Ventilation 0 0 0 0 0 18

Smoke alarm modes 1200 1600 2000 400 200 12

Minimum Outdoor Airflow 120 160 200 40 40 237

* Setting in CFM = tonnage of the unit multiplied by Parameter value in CFM/ton.

Standard Efficiency Energence A Box Unit with a BeltDrive TwoSpeed Motor. The speed is not parameter

selectable. During first stage cooling blower is at low speed, while blower runs at high speed in heating, second stage

cooling and smoke alarm (if configured), Ventilation may use low or high speed blower.

9.3.2. B Box (7.5 – 12.5 ton units)

Energence B Box 7.5 to 12.5ton MSAV units use direct driven blower (ultrahigh efficiency units only) or belt driven blower

with Variable Frequency Drive (VFD). Units have two compressors and on ultra high efficiency units they are set for tandem

operation. The actual blower speed and CFM delivered will depend on the flow restriction as well as the percent output. The

blower output for each mode of operation has been factory set, but it will need to be adjusted during test & balance on the

installed ductwork and the air delivery required for the application. The table below shows the default blower outputs

parameters as well as options for minimum damper position.

Refer to table 19 and 20 in Section 6.6 for detailed information on system operation in various configurations and operating

modes.

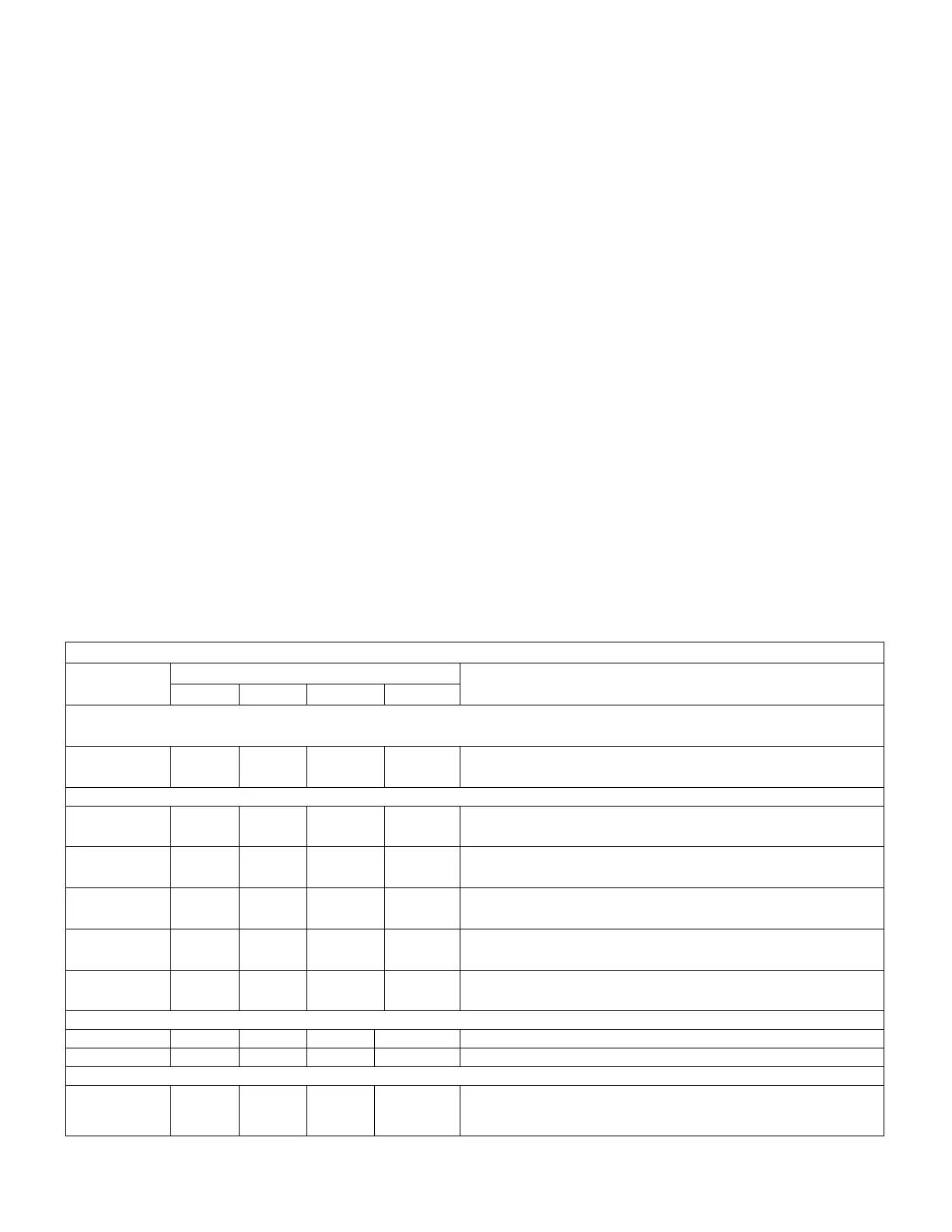

Table 36. B Box (2Compressor) Units with Multi-Stage Air Volume (7.5 12.5 ton)

Parameter

Capacity (tonnage)

Description

7.5 8.5 10 12.5

Note: Any changes to Smoke CFM setting must be adjusted before the other CFM settings.

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

12

3000

CFM

3400

CFM

4000

CFM

5000

CFM

Blower CFM during smoke detection.

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > BLOWER > SPEEDS)

13

3000

CFM

3400

CFM

4000

CFM

5000

CFM Blower CFM during heating.

14

2700

CFM

2200

CFM

3600

CFM

4500

CFM Blower CFM during high speed (2 compressors) cooling.

17

1950

CFM

3050

CFM

2600

CFM

3250

CFM

Blower CFM during low speed (1 compressor) and free cooling.

18

3000

CFM

3400

CFM

4000

CFM

5000

CFM Blower CFM during ventilation.

19

1195

RPM

N/A

1425

RPM

1655

RPM

Blower RPM for max CFM (applicable only to unit with blower direct drive)

SETUP > TEST & BALANCE (can also use SETTINGS > RTU OPTIONS > DAMPER)

9 0% 0% 0% 0% Damper min. position during LOW blower operation.

132 0% 0% 0% 0% Damper min. position during HIGH blower operation.

SETTINGS > RTU OPTIONS > EDIT PARAMETERS

29 101% 101% 101% 101%

Damper minimum position during G blower operation. (Setting parameter

29 to “101” disables parameter 29 and passes control to parameter 9 or

132)

Loading...

Loading...