Do you have a question about the Lennox PRODIGY2.0 and is the answer not in the manual?

Details the physical layout and connection ports of the M3 Unit Controller.

Describes system operation modes via thermostat, room sensor, or network.

Explains the five cooling staging options and configurations.

Details heating staging options for gas and electric units.

Covers minimum run-time, off-delay, and on-delay for compressors.

Explains compressor run-time and off-delay settings and defaults.

Covers high-pressure switch operation and lockout logic.

Explains low-pressure switch function and lockout occurrences.

Covers protection mechanisms for gas units, including limits and proof switches.

Explains fan operation during low ambient conditions.

Details compressor and fan configurations by box size.

Explains low ambient fan control using pressure switches.

Configures Supermarket Reheat operation via thermostat or humidity sensor.

Details Humiditrol reheat operation based on humidity sensor readings.

Details increased dehumidification using room sensor and over-cooling limits.

Steps to enable economizer and available configuration types.

Discusses economizer damper operation profiles during free cooling.

Configures compressor lockout and low ambient set points for free cooling.

Outlines checkout procedures for economizer operation.

Explains using IAQ sensors to control CO2 levels and damper position.

Details the default IAQ input and damper operation for DCV.

Explains OAC as an alternative to DCV for modulating outdoor air damper.

Describes BPC feature for modulating outdoor air damper to hold constant building pressure.

Explains M3 unit controller's capability to control power exhaust stages.

Explains M3 controller compatibility with VFDs for supply blower control.

Covers CAV unit bypass damper control for static pressure.

Explains analog output control using PID for CAV bypass damper.

Discusses auto cycling for discharge air cooling set point maintenance.

Covers automatic cycling for discharge air heating set point maintenance.

Details the optional BACnet module for MSTP network communication.

Procedure to determine relationship between motor torque and supply airflow.

Explains how the system measures and controls supply airflow.

Details various control modes available for the M3 unit controller.

Explains controller operation using a room sensor for heating and cooling.

Describes controller operation using a thermostat for heating and cooling.

Explains DCV for controlling outdoor air based on CO2 levels.

Explains controller operation for CAV units with room sensors.

Explains compressor staging for maintaining space temperature set point.

Covers controller operation for CAV units with wired thermostat or third-party controls.

Details M3 controller's role in activating compressors for cooling demand.

Explains 4-stage heating/cooling control with thermostats or third-party controllers.

Covers M3 controller's role in maintaining cooling discharge air temperature set point.

Covers controller operation for bypass zoning with 2-stage heating/cooling.

Describes bypass damper use for supply duct static pressure control.

Covers controller operation for bypass zoning with 4-stage heating/cooling.

Describes bypass damper control for supply duct static pressure.

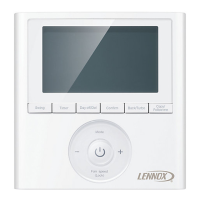

Overview of M3 unit controller inputs and outputs.

Visual representation of the main menu structure.

Shows operating mode, alarms, and network status.

Shows how alarms are displayed, including alarming value and event details.

Details the settings for Configuration ID 1 for various features.

Explains the settings for Configuration ID 2 related to unit features.

Recommends PC software for adjusting parameters and saving configuration files.

Explains the unit's ability to detect frequency, phasing, and voltage levels.

Lists M3 unit controller alarms and event codes with corresponding actions.

| Brand | Lennox |

|---|---|

| Model | PRODIGY2.0 |

| Category | Controller |

| Language | English |

Loading...

Loading...