Page 5

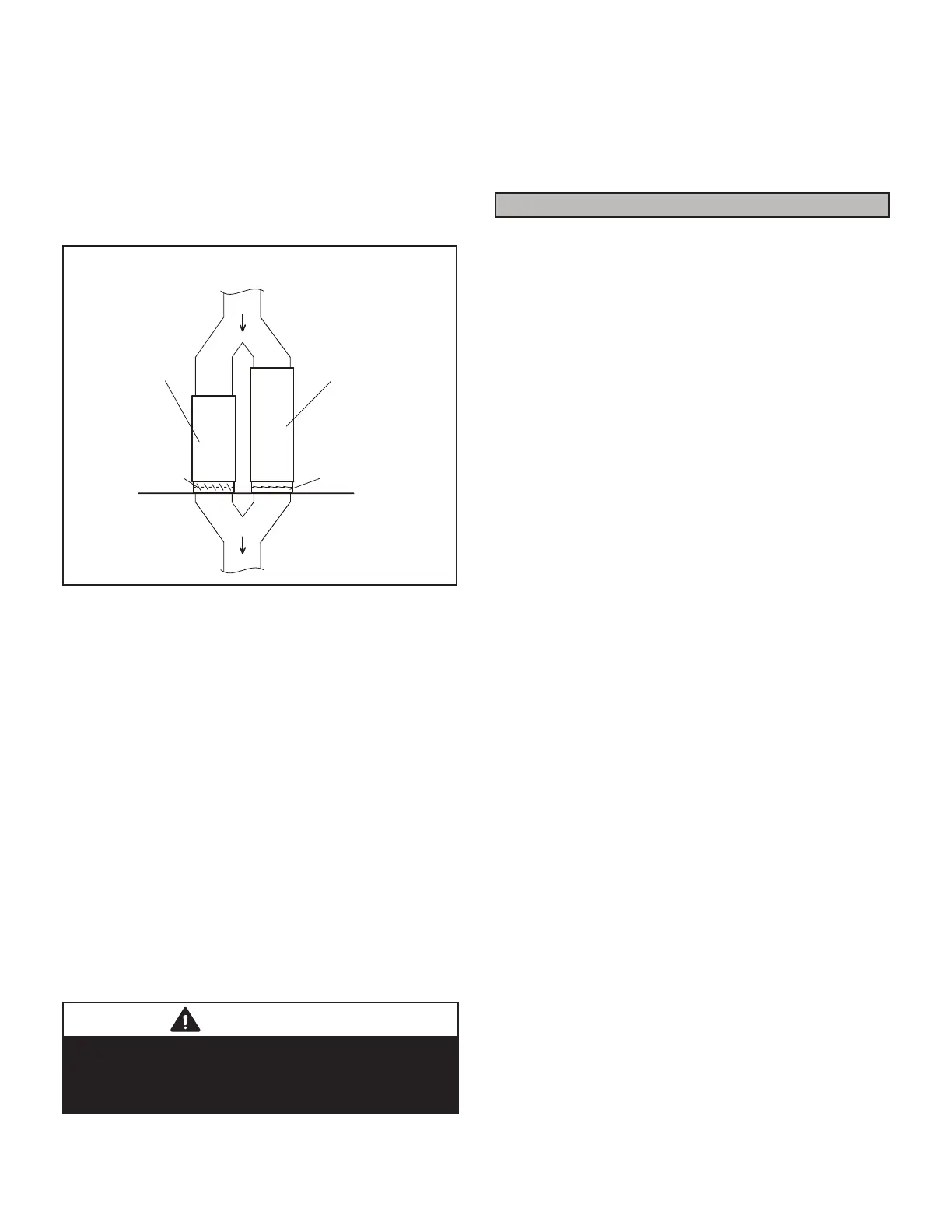

Installed in Combination with a Cooling Coil

When this furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of, cool-

ing units to avoid condensation in the heating compart-

ment. With a parallel ow arrangement, a damper (or

other means to control the ow of air) must adequately

prevent chilled air from entering the furnace (FIGURE 3).

If the damper is manually operated, it must be equipped to

prevent operation of either the heating or the cooling unit,

unless it is in the full HEAT or COOL setting.

AIR HANDLER

GAS UNIT

Dampers

(open during cooling

operation only)

Dampers

(open during heating

operation only)

FURNACE INSTALLED PARALLEL

WITH COOLING COIL

FIGURE 3

When installed, this furnace must be electrically grounded

according to local codes. In addition, in the United States,

installation must conform with the current National Elec-

tric Code, ANSI/NFPA No. 70. The National Electric Code

(ANSI/NFPA No. 70) is available from the following ad-

dress:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

NOTE - This furnace is designed for a minimum contin-

uous return air temperature of 60°F (16°C) or an inter-

mittent operation down to 55°F (13°C) dry bulb for cases

where a night setback thermostat is used. Return air tem-

perature must not exceed 85°F (29°C) dry bulb. See “Duct

System” on page 9 for installing the optional discharge

air sensor used to measure temperature rise. Sensor is

shipped with the unit.

In Canada, all electrical wiring and grounding for the unit

must be installed according to the current regulations of

the Canadian Electrical Code Part I (CSA Standard C22.1)

and/or local codes.

CAUTION

Do not set thermostat below 60F (16C) in heating mode.

Setting below 60F (16C) reduces the number of heating

cycles. Damage to the unit may occur that is not covered

by the warranty.

The SLP99DFV furnace may be installed in alcoves, clos-

ets, attics, basements, garages, and utility rooms.

This furnace is not designed for installation in mobile

homes, recreational vehicles, or outdoors.

Never use an open ame to test for gas leaks. Check all

connections using a commercially available soap solution

made specically for leak detection.

Use of Furnace as Construction Heater

Units may be used for heating of buildings or structures

under construction, if the following conditions are met to

ensure proper operation:

DO NOT USE THE UNIT FOR CONSTRUCTION HEAT

UNLESS ALL OF THE FOLLOWING CRITERIA ARE

MET:

• Furnace must be in its nal location. The vent system

must be permanently installed per these installation in-

structions.

• Furnace must be installed as a two pipe system and

one hundred percent (100%) outdoor air must be pro-

vided for combustion air requirements during construc-

tion.

• A room thermostat must control the furnace. The use

of xed jumpers that will provide continuous heating is

prohibited.

• The input rate and temperature rise must be set per the

furnace rating plate.

• Supply and Return air ducts must be provided and

sealed to the furnace. Return air must be terminated

outside of the space where furnace is installed.

• Return air temperature range between 60°F (16°C) and

80°F (27°C) must be maintained.

• MERV 11 or greater air lters must be installed in the

system and must be regularly inspected and maintained

(e.g., regular static checks and replaced at end of life)

during construction.

• Blower and vestibule access panels must be in place on

the furnace at all times.

• The furnace heat exchanger, components, duct system,

and evaporator coils must be thoroughly cleaned follow-

ing nal construction clean−up.

• Air lters must be replaced upon construction comple-

tion.

• All furnace operating conditions (including ignition, in-

put rate, temperature rise and venting) must be veried

in accordance with these installation instructions.

EQUIPMENT MAY EXPERIENCE PREMATURE COM-

PONENT FAILURE AS A RESULT OF FAILURE TO FOL-

LOW THE ABOVE INSTALLATION INSTRUCTIONS.

FAILURE TO FOLLOW THE ABOVE INSTALLATION IN-

STRUCTIONS VOIDS THE MANUFACTURER’S EQUIP-

MENT LIMITED WARRANTY. LENNOX DISCLAIMS

ALL LIABILITY IN CONNECTION WITH INSTALLER’S

FAILURE TO FOLLOW THE ABOVE INSTALLATION IN-

STRUCTIONS.

Loading...

Loading...