System bus (CAN) with Ser vo PLC & Drive PLC

Configuration

3-9

l PLC-Systembus EN 1.1

3.11 Diagnostics

The following codes can be used for diagnostics:

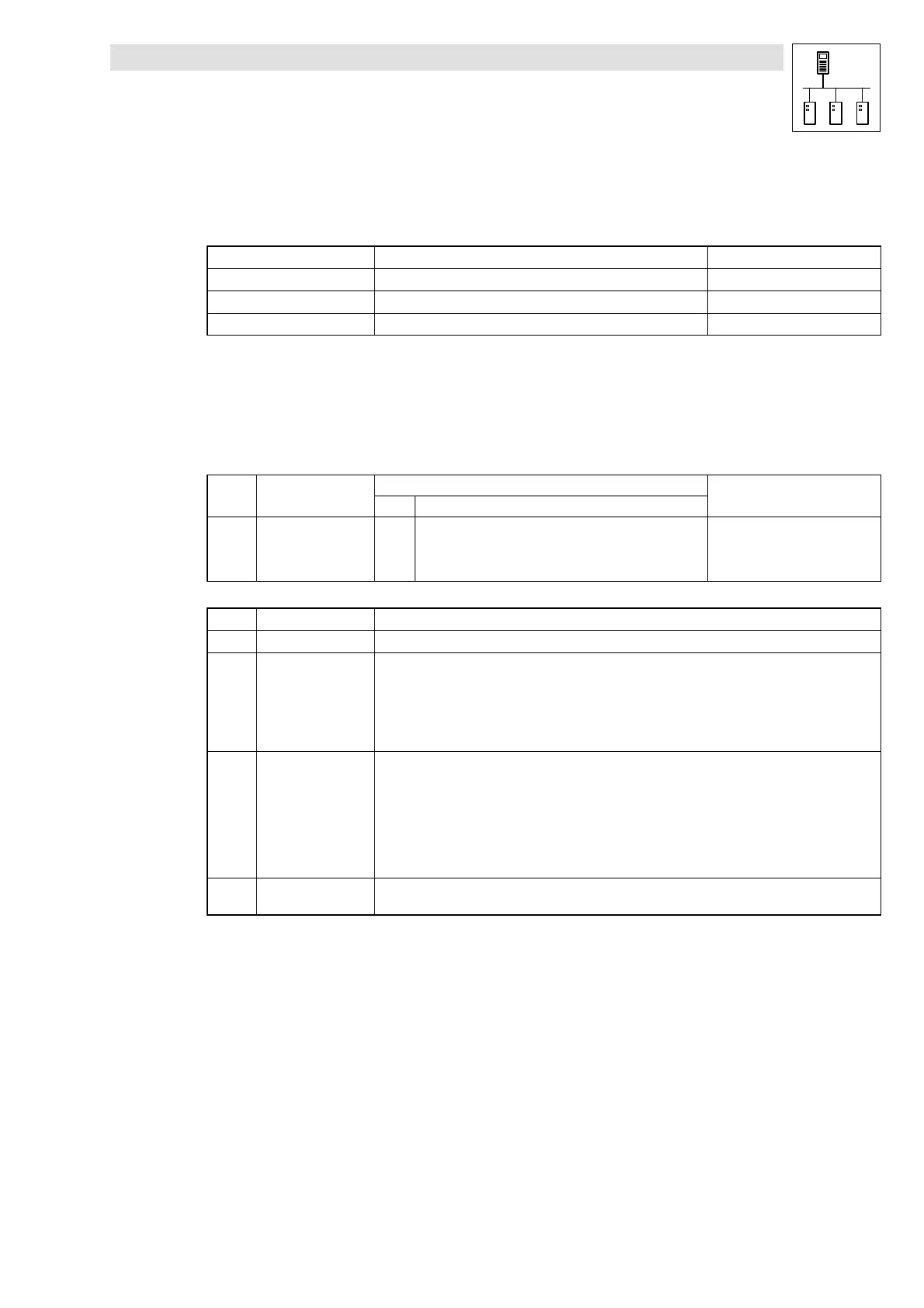

Code Display in f ormation Info

C0359 Operating state of the system bus Chapter 3.11.1 ^ 3- 9

C0360 Number of transmitted and received telegrams Chapter 3.11.2 ^ 3-10

C0361 Bus load (in %) Chapter 3.11.3 ^ 3- 10

• Settings cannot be made via these codes.

3.11.1 Operating state of the system bus

Via C0359 you can display the operating state of the system bus:

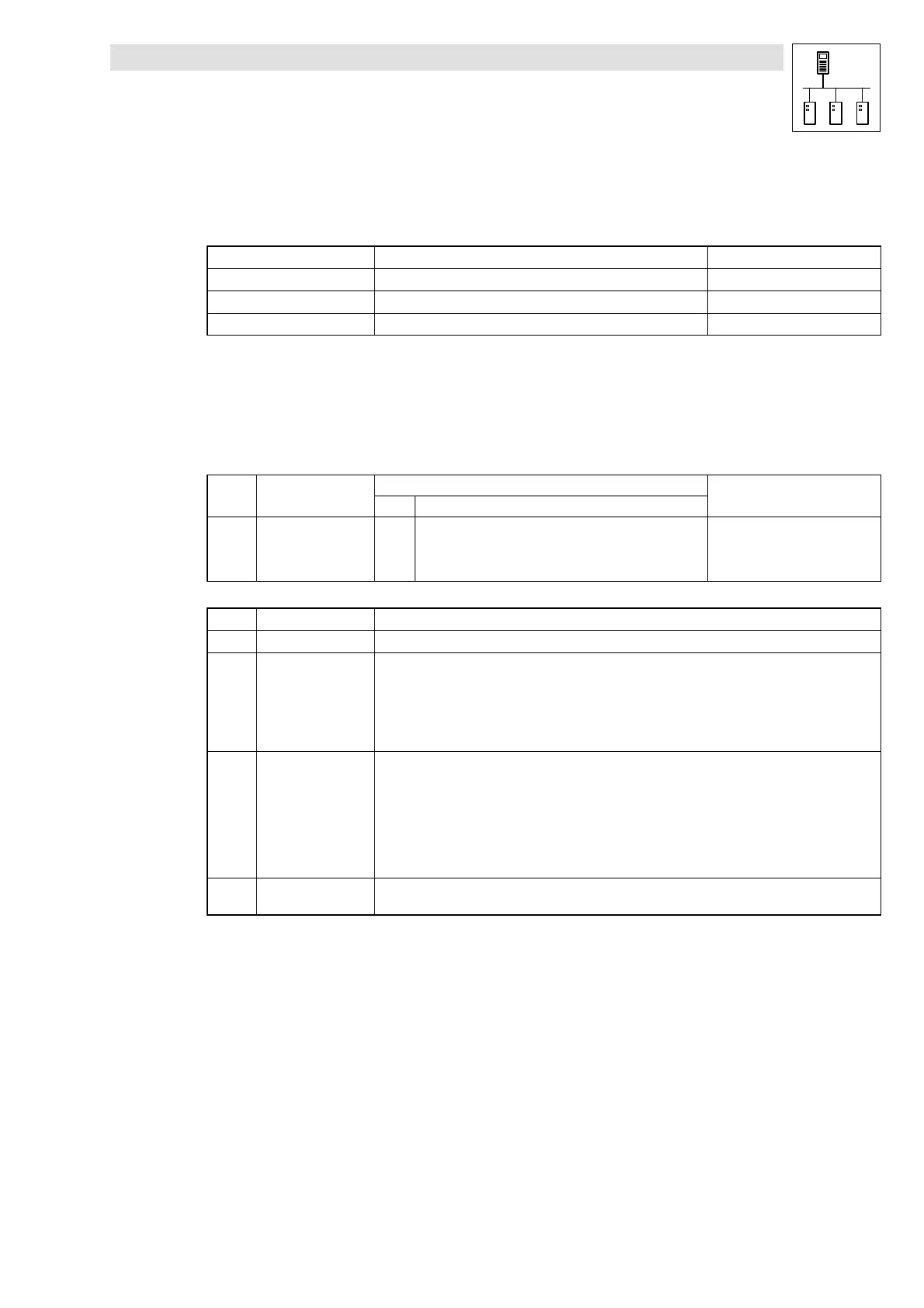

Code LCD

Possible settings

Info

Lenze Choice

C0359 CAN state

g

0 operational

1 Pre-operational

2 Warning

3BusOff

System bus status

C0359 Operating state Info

0 operational The system bus is operational. The PLC can transmit & receive parameter and process data.

1 Pre-operational The PLC can transmit & receive parameter data.Process data are ignored.

A status change from pre-operational to operational can be initiated by:

• the CAN master ^ 3-1

• a reset node

– via C0358, if the PLC was configured as a “quasi” master.

^ 3-6

– via the binary input signal “reset node” at the CAN_Management SB

^ 6-18

2 Warning The PLC has received faulty telegrams and no longer takes an active part in the system bus, i.e. it is no

longer possible to transmit data from the PLC.

Possible causes:

• A missing bus termination

• Insufficient screening

• Potential differences in the grounding of the control electronics

• the bus load is to o high

• The PLC is not connected to the system bus

3 Bus Off The PLC has decoupled itself from the system bus because too many faulty telegrams were received.

• The reaction t o this status can be configured via C0595. ^ 3-7

Loading...

Loading...