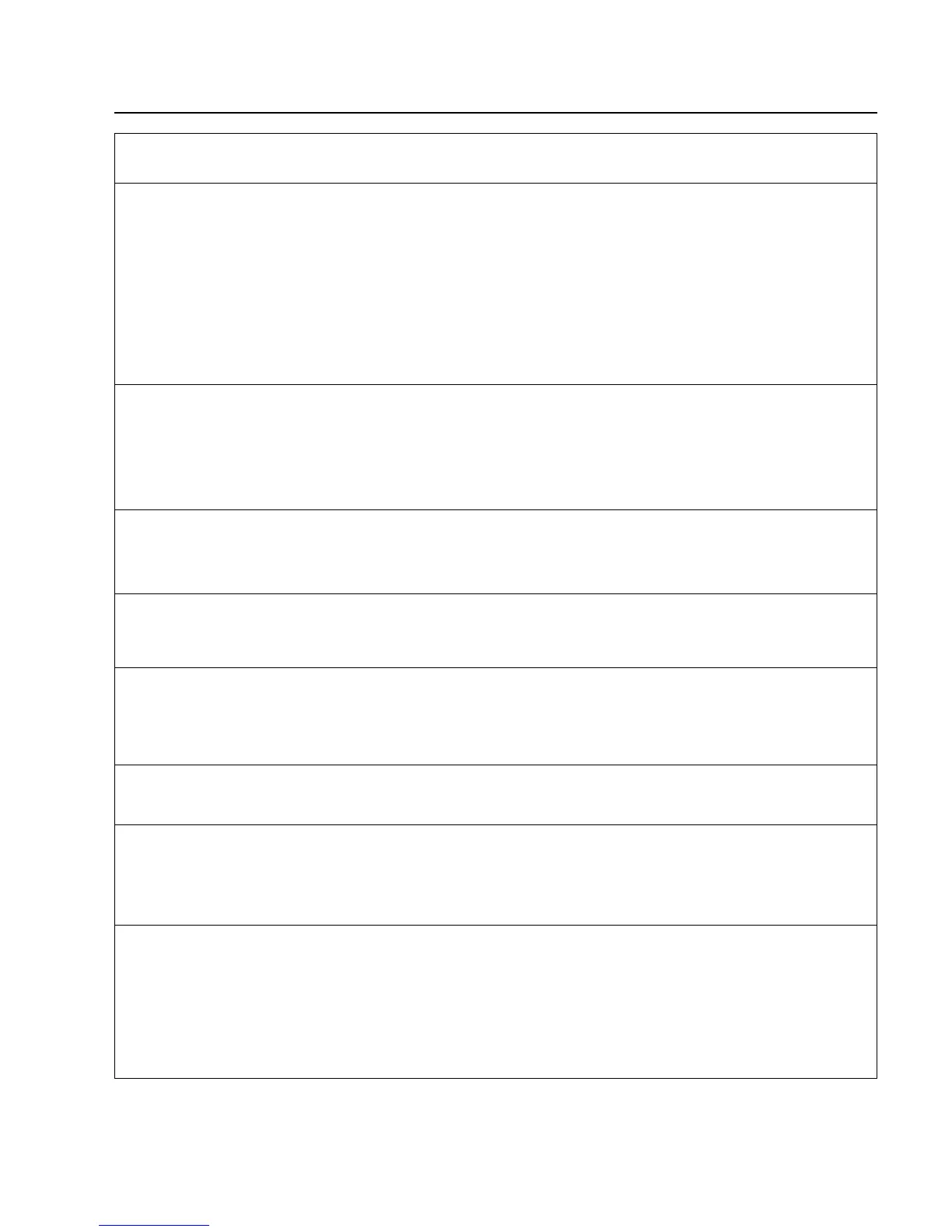

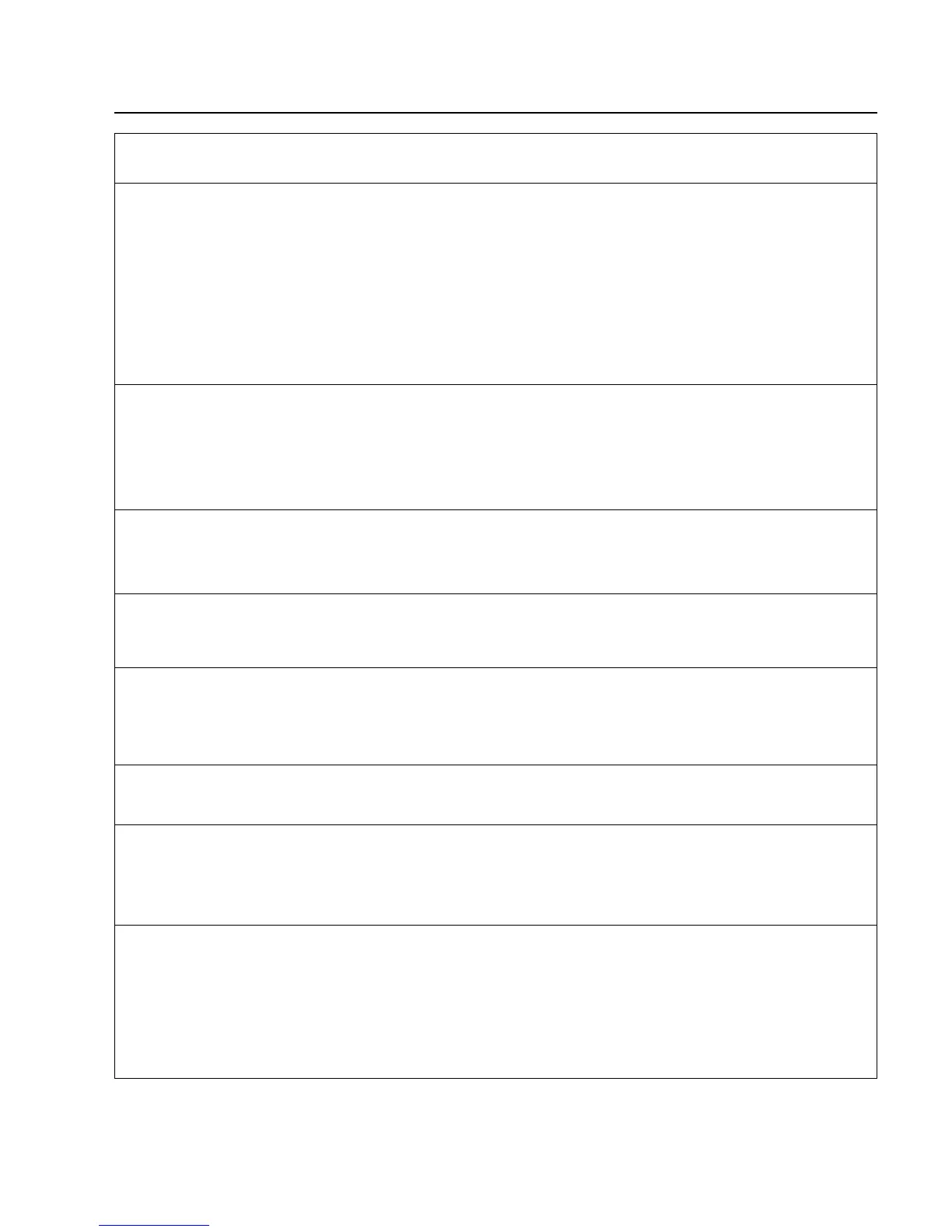

Troubleshooting

51

GA 05.139/1.02 - 06/99

Warning Message

on Display

TMS

TMS temperature sensor

reads a temperature higher

than the TMS setpoint +5 °C.

Unbalanc. PVW13

Unbalanc. PVW24

Unbalanc. PZ12

A rotor displacement excee-

ding the warning threshold

occured. The code designa-

tes the affected axis.

Overload

The rotational speed drop-

ped below normal operation

frequency.

Mains down

The converter is in the gene-

rator mode.

Op. Without Purge

The warning indicates that a

C/CT type of pump is opera-

ted while the purge gas

valve is closed.

Protection

The pump drive is blocked.

PK Communication

Converter does not commu-

nicate with the memory chip

inside of the pump.

Measures

Apply cooling water according to specificati-

ons. Check cooling water tubes for deposits.

See also Section 2.6.

Check the TMS setpoint (default 62 °C). For

the correct setting refer to Section 4.3.4.

Check chamber temperature.

If the red LED at the water valve is on dis-

connnect and connect the connector. The

valve must make noises. If not contact Ley-

bold.

If warning message persists contact Leybold

service.

Check the chamber pressure during operati-

on.

Contact Leybold service.

Reduce backing pressure. Additionally,

check process gas flow.

Set parameter „Normal Operation“ to default

95%. Refer also to Section 4.3.3.

Reconnect converter to the mains.

Switch on the converter.

Set purge gas function to Purge ON. (Key

panel or control connector X14).

Deactivate „Emergency off“ via control plug

X14.

Check BEARING connector and cable for

damages or bent pins. Contact Leybold ser-

vice if the cable is damaged.

Contact Leybold service.

Possible Cause

Cooling water flow too low or cooling water

temperature too high.

Wrong TMS temperature setpoint.

Temperature at the high-vacuum connection

flange or at the isolation valve is much

higher than 85 °C.

Water valve malfunction.

Mechanical shocks, perhaps due to tool

maintenance.

Shock venting.

Converter failure.

Backing pressure too high during operation.

Parameters „Normal Operation“ are not set

correctly.

Mains interrupted or converter switched off

during operation of the pump.

Purge gas function disabled.

Emergency off active.

BEARING cable damaged.

Memory chip inside of magnetic bearing car-

tridge malfunctioning.

Loading...

Loading...