Installation

14

GA 05.139/1.02 - 06/99

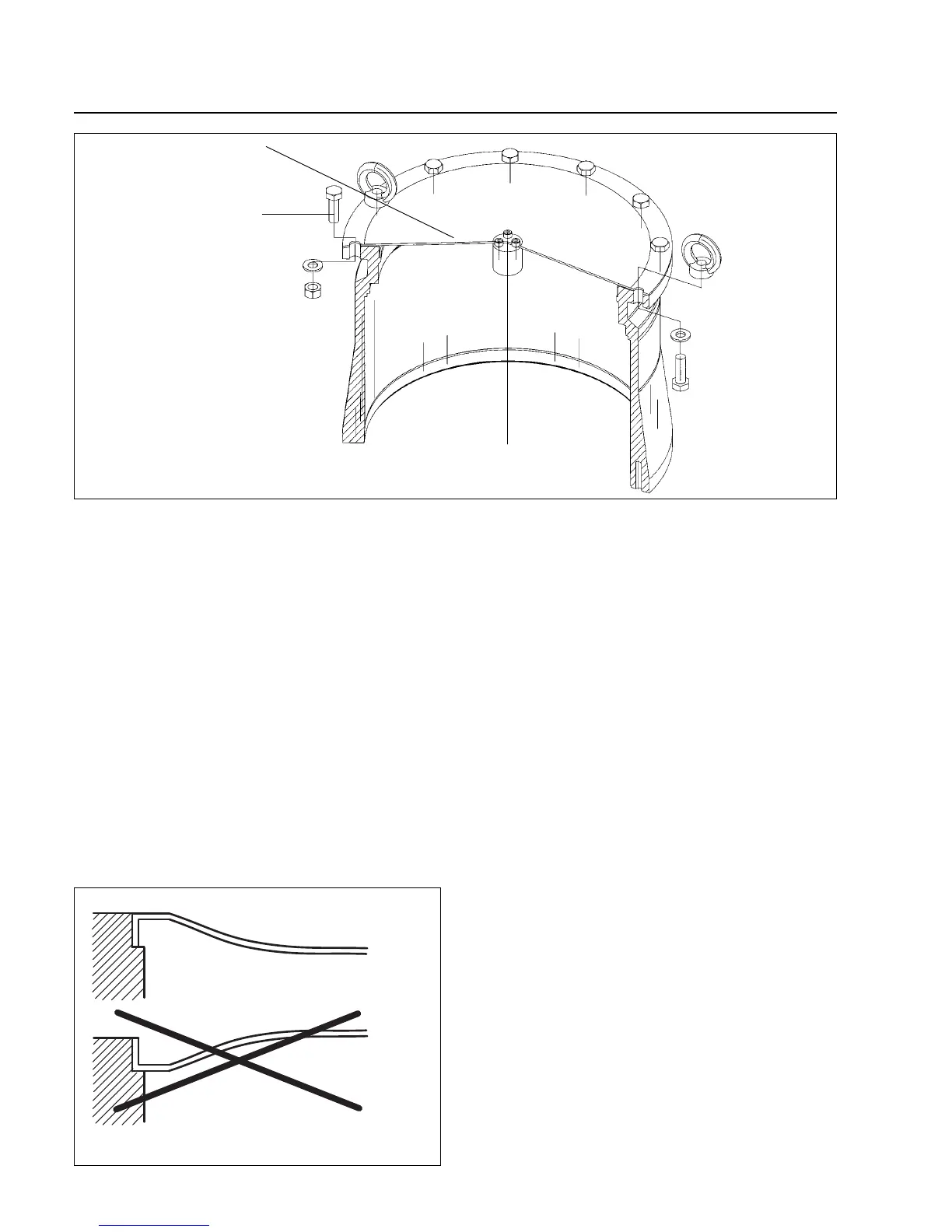

1

2

1 Aluminum cover

2 Screws

Fig. 10 Removing the transport seal

2.3 Operating environment

When using the MAG inside a magnetic field, the

magnetic induction at the pump housing must not ex-

ceed 5 mT; (1 mT (milliTesla) = 10 G (Gauß))

Exceeding this limit can cause excessive rotor heating

due to the eddy currents generated in this situation. It is

therefore necessary to provide suitable shielding in such

cases.

The standard version of the MAG is resistant to radiation

at levels up to 10

3

Gy. (1 Gy (Gray) = 100 rad)

The ambient temperature must not exceed 40°C

(104 °F).

The noise level when the pump is running is below 70

dB(A). No acoustic insulation is required.

2.4 Connecting the MAG to

the vacuum chamber

The MAG is shipped in a sealed PE bag with desiccant.

Do not open the package until immediately before instal-

ling.

Do not remove the covers and blanking flanges until you

are ready to make the connections, to ensure that the

MAG is installed under the cleanest possible conditions.

Pay attention to maximum cleanliness when connecting.

Remove the transport seal from the intake flange. To do

so unscrew the screws (10/2) and remove the aluminum

cover. We recommend saving the transport seal for

maintenance.

Foreign objects entering the pump through the high-va-

cuum flange can cause serious damage to the rotor.

That’s why the splinter guard must always be installed.

Damages caused during operation without the splinter

guard are excluded from warranty.

Caution

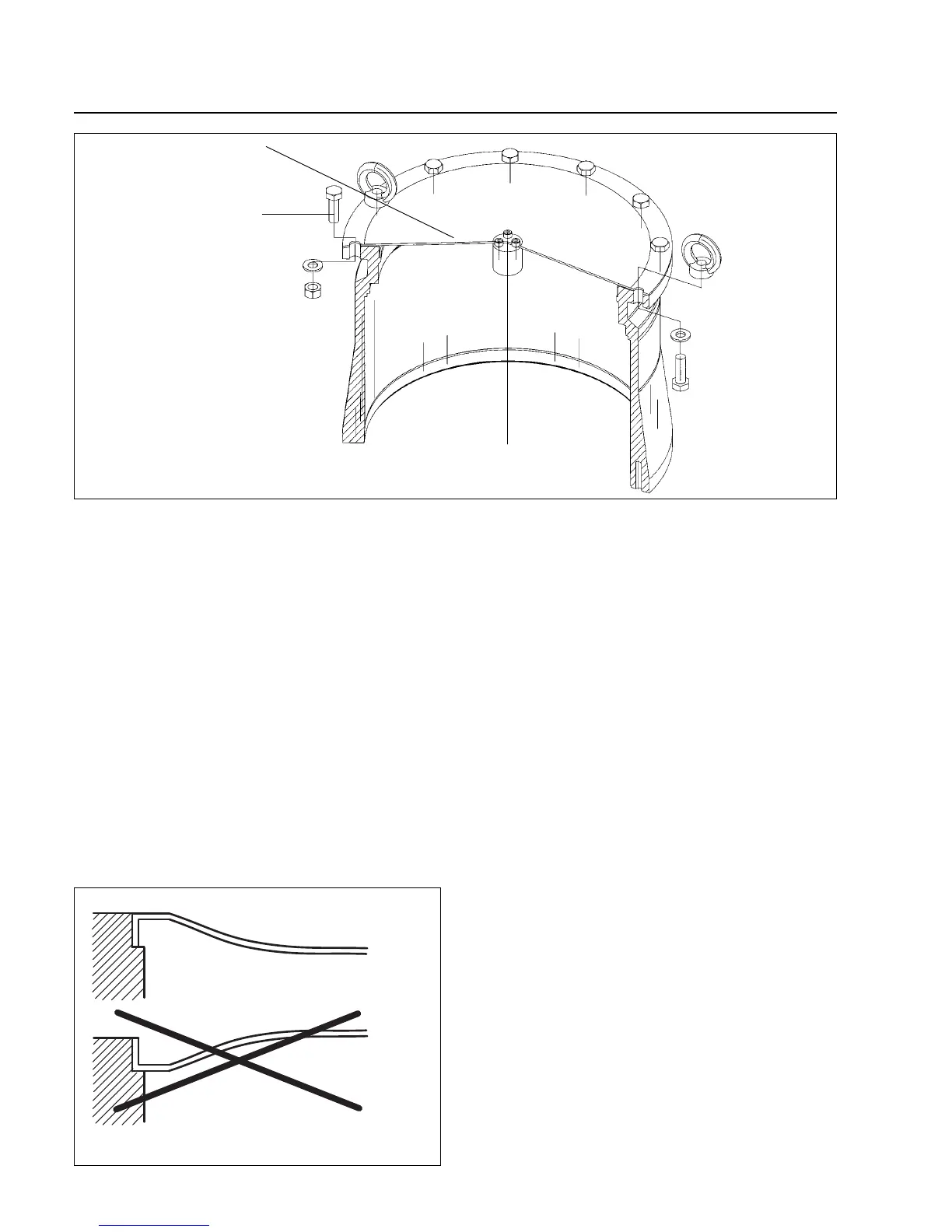

Install the splinter guard as shown in Fig.

11. Installing the splinter guard upside down

may lead to contact between splinter guard

and rotor during fast venting of the pump.

Correct

Wrong

Fig. 11 Installing the splinter guard

Loading...

Loading...