Description

10 GA01601_002_C1 - 03/2018 - © Leybold

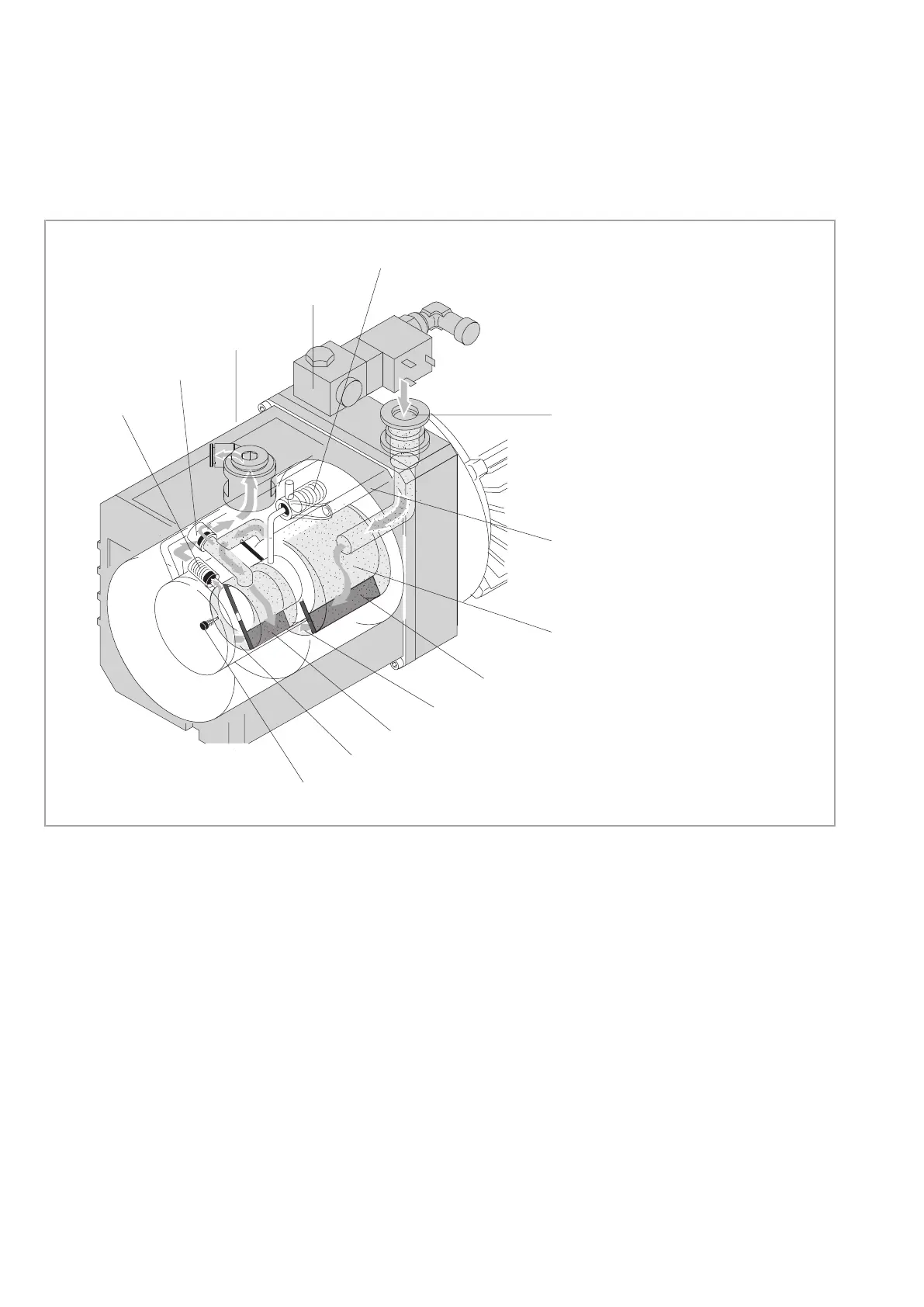

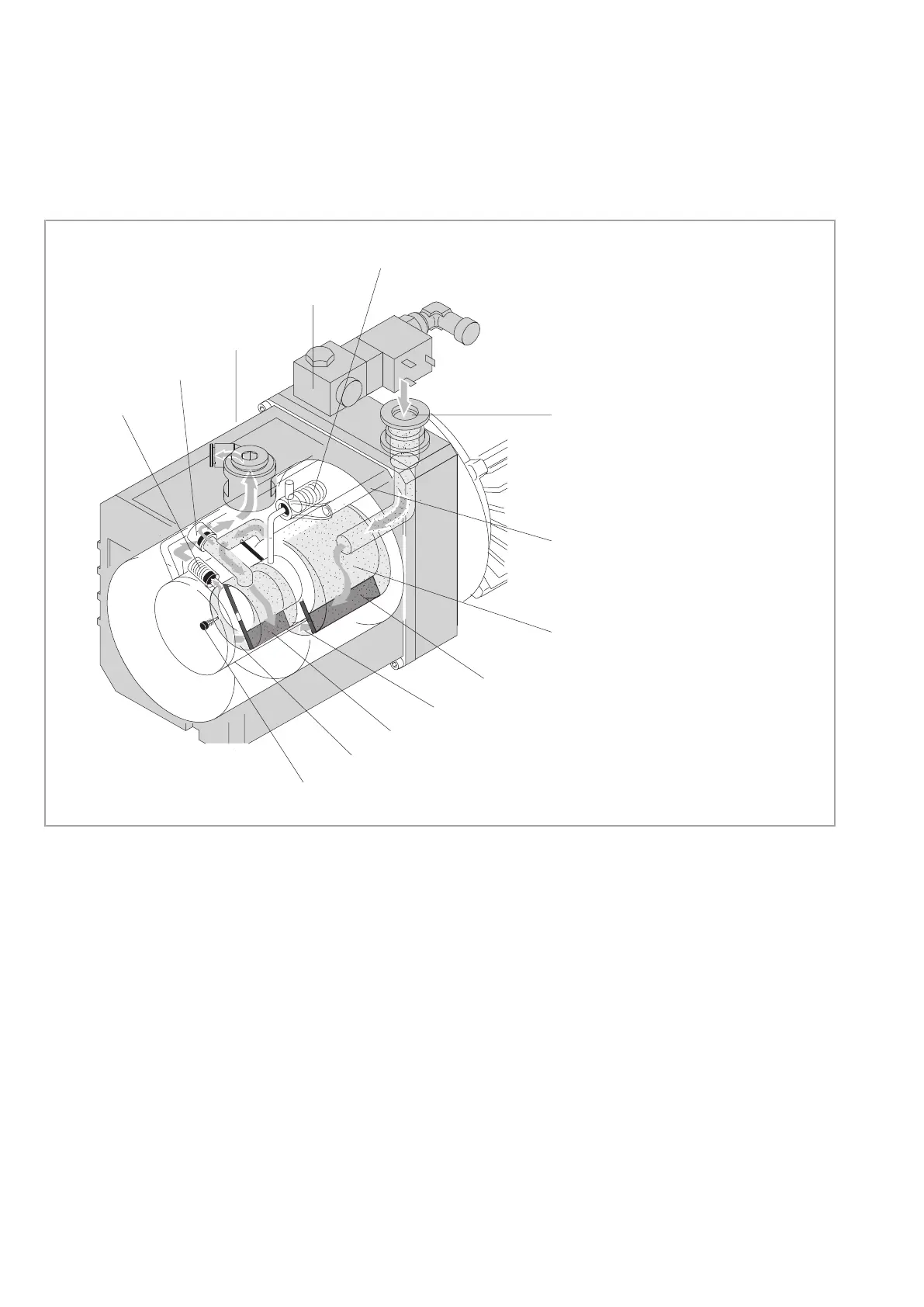

1.1 Function

The rotor (2/5) which is eccentrically arranged in the pump housing (pump

chamber) has two radially slidingvanes (2/6 and 2/8) which divide the pump

chamber ofthe pump into several chambers.

The volume of each chamber changes periodically witheach turn of the rotor

so that the gas at the intake port(2/3) is sucked in. The gas enters the pump

chamber, and after the admission aperture has been sealed off by the vane,

the gas is compressed and moved on.

The compressed gas is ejected from the pump chamberthrough the exhaust

valve. Oil which is entrained in the gas is roughly separated by an internal

demister and at the same time any mechanical contaminations are also

removed from the oil. The gas exits the pump through the exhaust port

(2/13).

Oil injected into the pump chamber serves the purpose of sealing and lubri-

cation. The knocking noise (oil slap) which normally occurs when the pump

approaches its ultimate pressure is avoided by injecting a small amount of air

into the oil so that a silencing effect is attained.

2

3

4

5

6

7

8

9

10

12

13

1

11

1 Gas ballast valve

2 Tandem valve

(vacuum protection)

3 Intake port

4 Oil feed (oil pump)

5 Rotor

6 Vane (HV)

7 High vacuum stage

(pump chamber)

8 Vane (FV)

9 Forevacuum stage

(pump chamber)

10 Non-return valve

11 Exhaust valve

12 Bypass valve

13 Exhaust port

Fig. 2 Principle of operation of the TRIVAC D 2,5 E-LD

Loading...

Loading...