Maintenance

27GA01601_002_C1 - 03/2018 - © Leybold

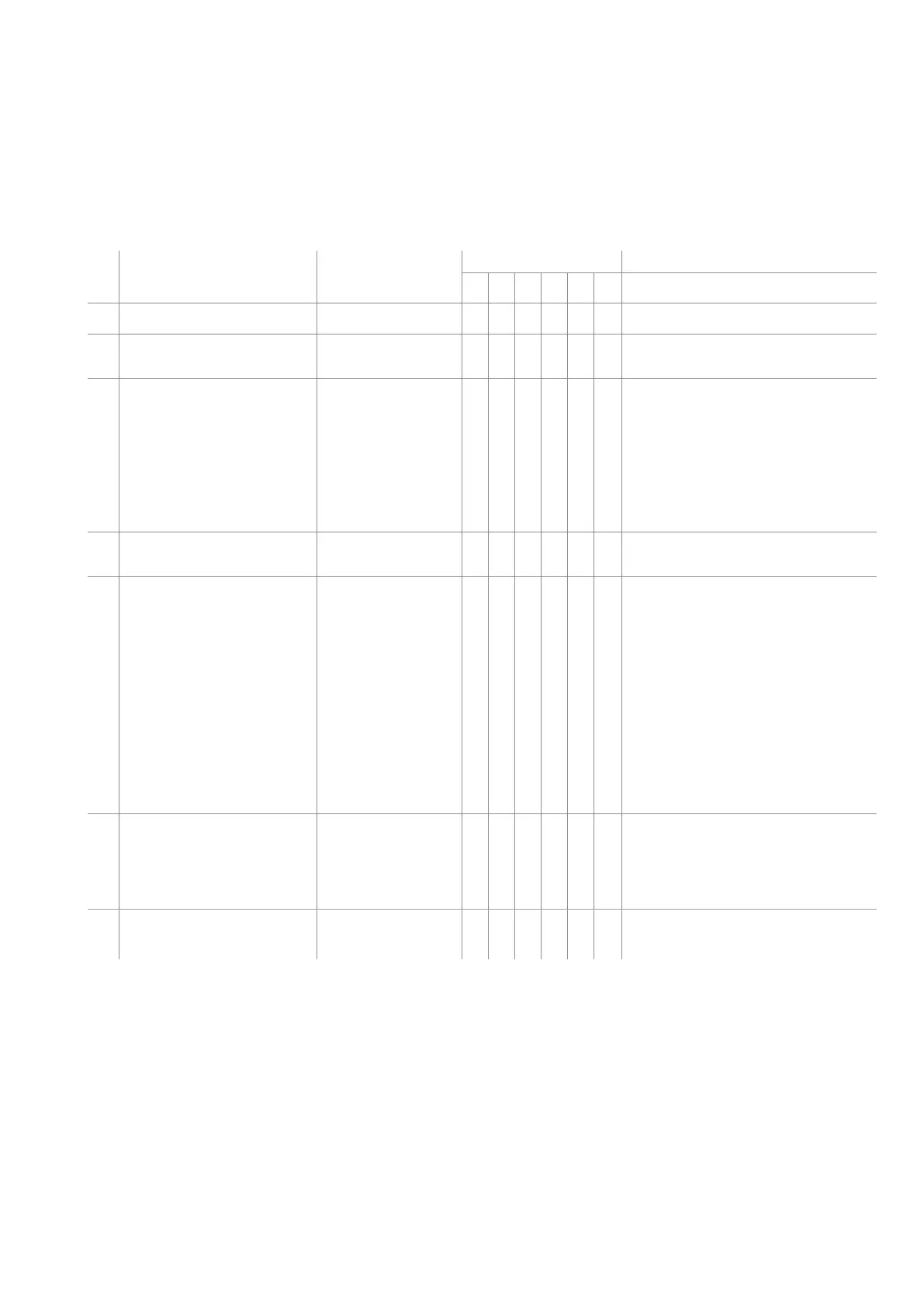

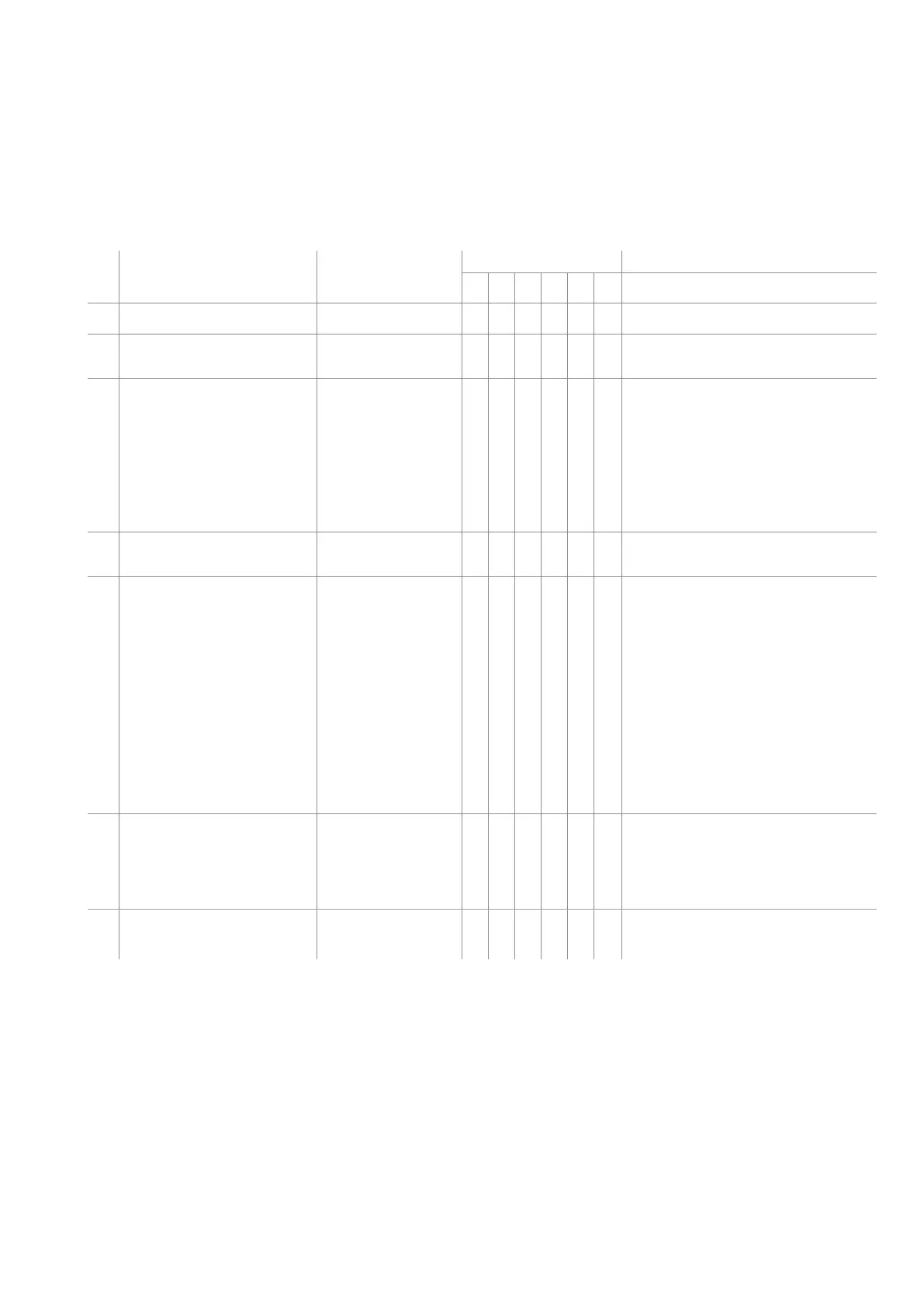

5.1 Maintenance Plan

Nr. Rotary vane pump

TRIVAC D 2,5 E-LD

Measurement/test quantity

Operating/auxiliary

materials

Interval Remarks

VE VP t 6m a n-a

Refer also to the Operating Instructions Section:

individual components.

1 Operate the pump for at least 1 h with

gas ballast..

x Condensed water is thus removed from the oil.

2 Check the oil level,

if required change the oil.

Oil: LVO 310 or special and

alternative oils see Chapter

5.3

x x Refill: Only after the pump has been switched off.

3 Clean the internal demister,

change it as required.

Suitable cleaning agent. x Already clean before the maintenance interval has

elapsed when the noise level increases.

n Clean internal demister with cleaning agent.

n Replace the defective internal demister.

n Dispose of the defective internal demister as

special waste. Cleaning agent according to natio-

nal/international specifications.

Observe the safety regulations when using

cleaning agents.

(parts are contained in Maintenance Kit 1)

(see Section 7.1)

4 Check the coupling bushings for

damage and wear.

3 Check also in advance of the scheduled mainte-

nance interval in case of extreme noise (parts are

contained in Repair Set 1, see Section 7.1)

5 Change the oil

and

Oil: LVO 310 or special-

and alternative oils

x Oil change:

n First oil change after 100 operating hours.

n Further oil changes: at least every 2000 - 3000

operatinghours or after one year.

n Pump switched off and cold.

Exchange the oil while the pump is cold so as to

avoid releasing adsorbed gases.

clean the oil level glass. Suitable cleaning agent and

compressed air.

Clean the oil level glass with a cleaning agent and

blow it out with compressed air under a suction

hood.

Use cleaning agents only corresponding to the

national/international specifications.

Observe the safety regulations when using

cleaning agents

Quantity of oil: see Section 1.3

Oil disposal: see Section 8

8 Check the fan of the pump and motor

as well as the cooling fins on the

motor for deposits, and clean as

required.

Brush and industrial

vacuum cleaner.

x Already clean before the maintenance interval has

elapsed when the pump or the motor gets too

warm.

Caution: switch off the pump and ensure that it

cannot run inadvertently (disconnect from the

mains).

7 Full maintenance Maintenance-Kit 2 3 Clean and perform maintenance on the pump as

described in the instructions included with

Maintenance Kit 2 (see Section 7.1).

Key to maintenance plan

VE = Maintenance before switching on the

system

VP = Maintenance before starting production

t = Daily maintenance

6m = Six monthly maintenance

a = Annual maintenance

n-a = Maintenance every n years

We recommend that you service the pump every two years covering the following:

n Cleaning

n Checking the individual components

n Exchange of all seals

n Functional check

This service should be run by the Leybold - Service.

Loading...

Loading...