Maintenance

33GA01601_002_C1 - 03/2018 - © Leybold

Make sure to fit the gasket for the oil box (7/9) with the flat side in the

groove, see item 10 in Fig. 7.

Torque for the hex. socket screws (7/3) is 5.5 Nm.

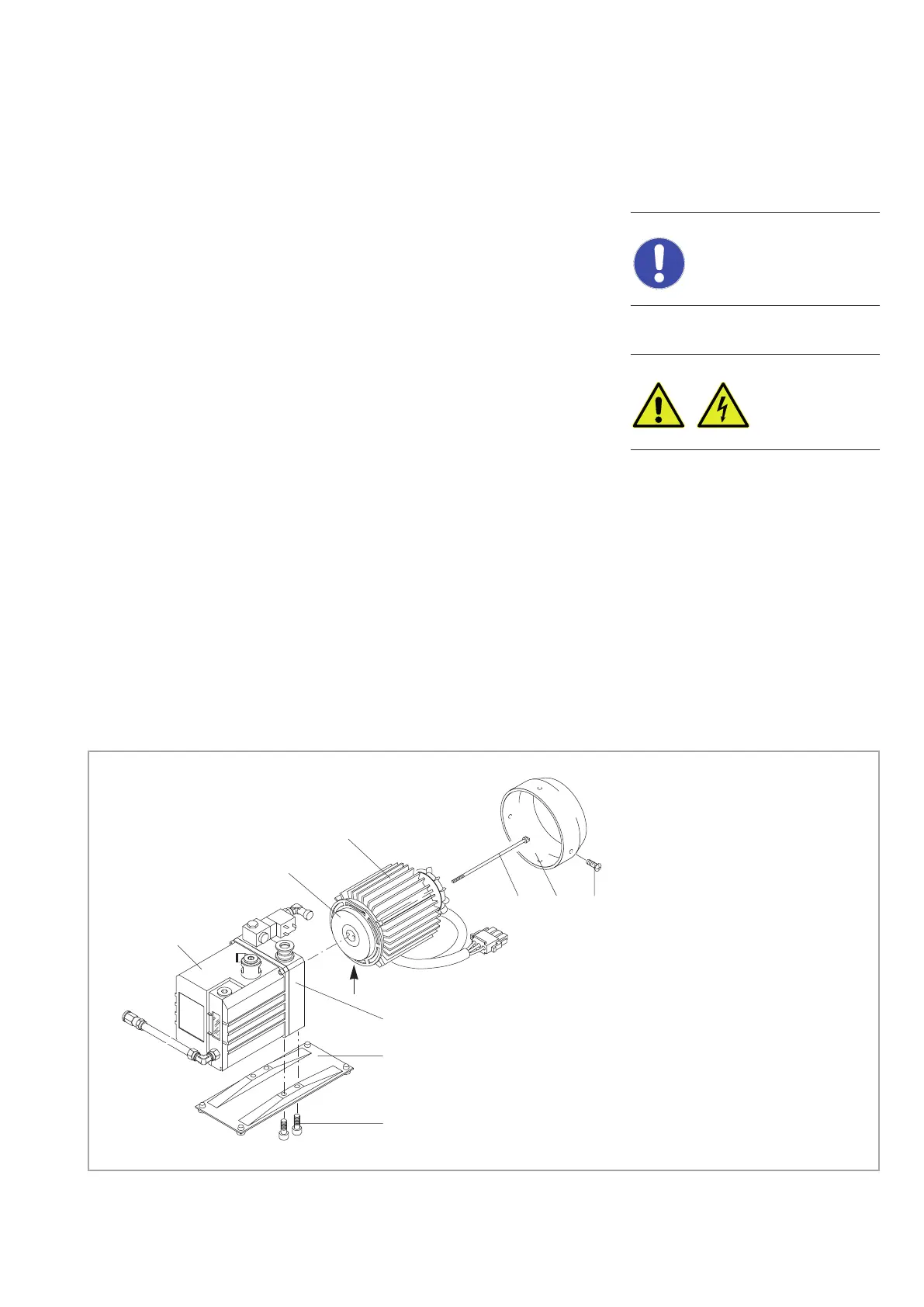

5.6 Disassembly and Reassembly of the Electric Motor

Risk due to high voltages

Death or severe injury caused by an electric shock!

Before starting work, always disconnect the motor from the mains. Pull the

mains plug. Observe Safety Informations 0.2.

Required tools: Hex. socket screw key size 4,

We recommend that you remove the foot (8/8) of the pump.

Place the pump on the front side of the oil box (8/1).

Remove the four hex. screws (8/4) from the fan cowl (8/5).

Detach the fan cowl.

Unscrew the tie rod (8/6).

Detach the motor (lever off using two screwdrivers inserted in parallel

between the end plate A and the HV bearing piece (8/2 and 8/7).

Clean all parts and make sure that they are in perfect condition; replace any

parts as required.

NOTICE

DANGER

1

6

2

4

3

5

7

8

9

Fig. 8 Disassembly and assembly of the electric motor

1 Oil box

2 End plate A

3 Electric motor

4 Mounting bolts (4x)

5 Fan cowl

6 Tie rod

7 HV bearing piece

8 Foot of the pump

9 Hex. socket screws (4x)

Loading...

Loading...