00

Jj

§

()

=

-

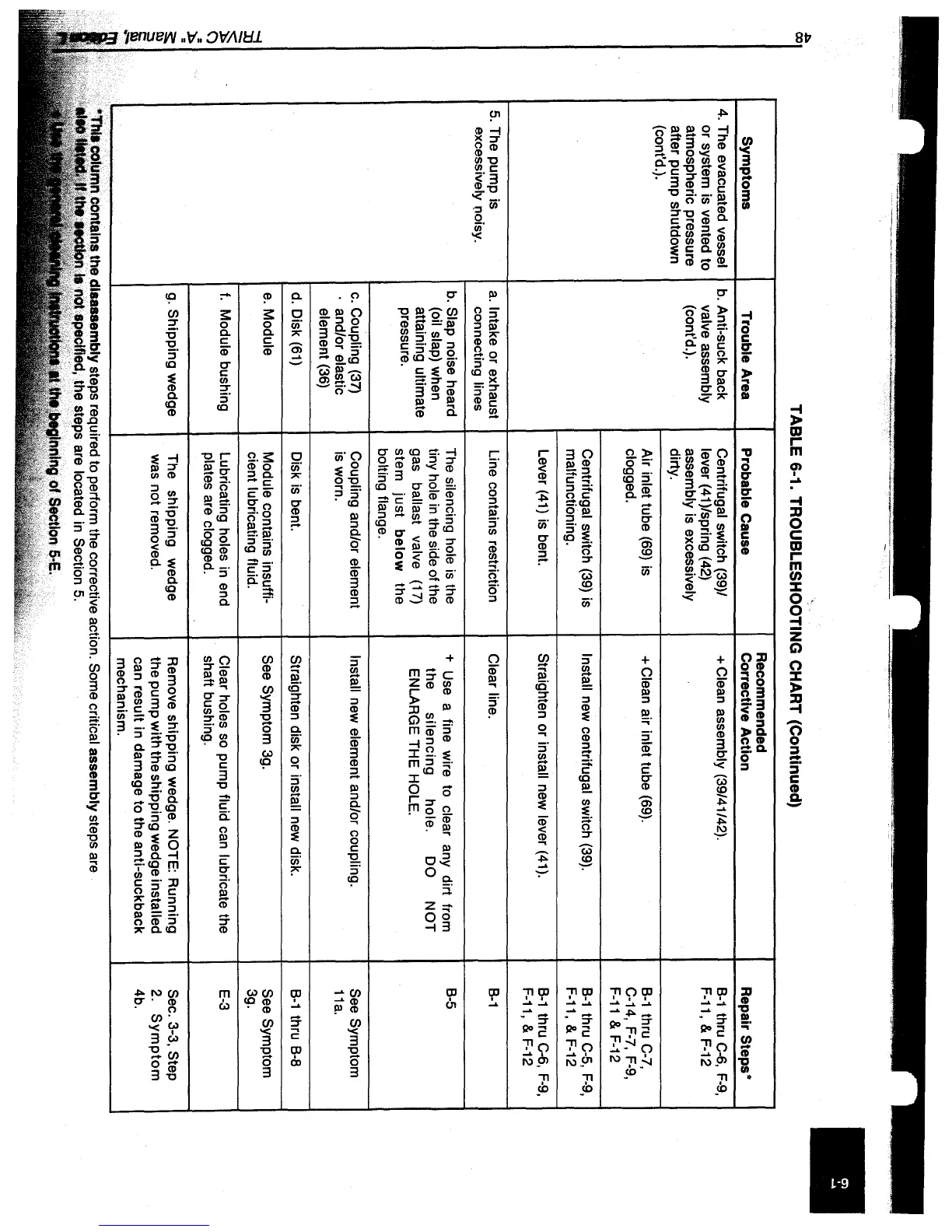

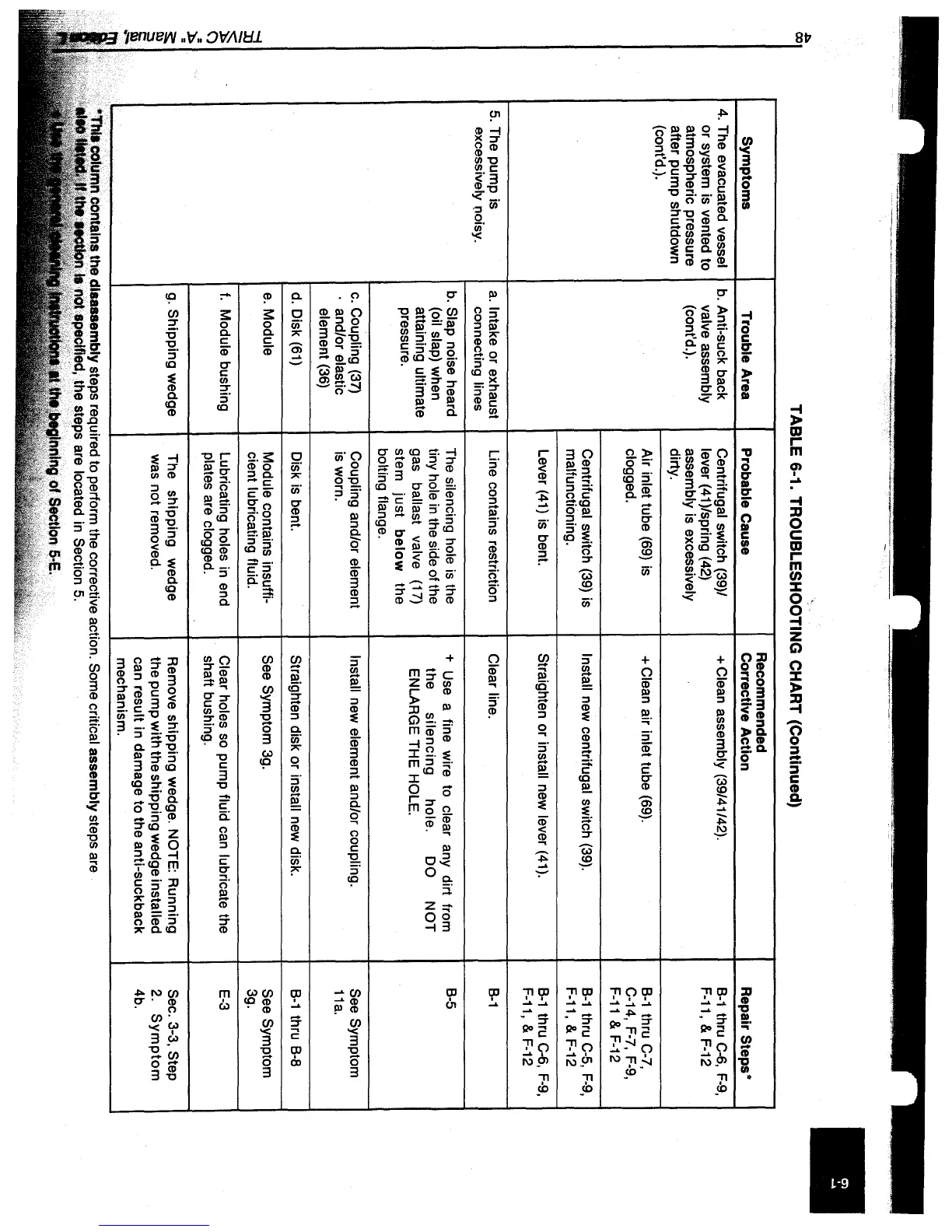

Symptoms

4.

The evacuated vessel

or system is vented to

atmospheric pressure

after pump shutdown

(cont'd.).

5.

The pump is

excessively noisy.

TABLE 6-1. TROUBLESHOOTING CHART (Continued)

Recommended

Trouble

Area

Probable Cause Corrective

Action

b.

Anti-suck back

Centrifugal switch (39)/

+ Clean assembly (39/41142).

valve assembly lever

(41

)/spring

(42)

(cont'd.).

assembly is excessively

dirty.

Air inlet tube

(69)

is

+ Clean air inlet tube

(69).

clogged.

Centrifugal switch

(39)

is

Install new centrifugal switch

(39).

malfunctioning.

Lever

(41)

is bent. Straighten or install new lever

(41).

a.

Intake or exhaust

Line contains restriction

Clear line.

connecting

lines

b.

Slap noise heard

The silencing hole

is

the

+ Use a fine wire to clear any dirt from

(oil slap) when

tiny hole

in

the side of the

the

silencing

hole.

DO

NOT

attaining ultimate

gas ballast valve

(17)

ENLARGE THE HOLE.

pressure.

stem

just

below

the

bolting flange.

c.

Coupling

(37)

Coupling and/or element Install new element and/or coupling.

. and/or elastic

is worn.

element

(36)

d.

Disk

(61)

Disk is bent.

Straighten disk or install new disk.

e.

Module

Module contains insuffi-

See Symptom 3g.

cient lubricating fluid.

f.

Module bushing

Lubricating holes in end

Clear holes

so

pump fluid can lubricate the

plates are clogged.

shaft bushing.

g.

Shipping wedge The shipping wedge Remove shipping wedge. NOTE: Running

was not removed.

the pump with the shipping wedge installed

can result in damage to the anti-suckback

mechanism.

dIsassembly steps required to perform the corrective action. Some critical assembly steps are

specified, the steps are located

in

Section

5.

'tnl",..

ftf

SectIon

6-E.

Repair Steps *

B-1

thru

C-6,

F-9,

F-11, &

F-12

B-1

thru

C-7,

C-14,

F-7, F-9,

F-11&F-12

B-1

thru

C-5,

F-9,

F-11,&F-12

B-1

thru

C-6,

F-9,

F-11,

&

F-12

B-1

B-5

I

See Symptom

11a.

B-1

thru

B-8

See Symptom

3g.

E-3

Sec. 3-3, Step

2.

Symptom

4b.

Loading...

Loading...