0·15

CONTINUED

If necessary

for

cleaning, remove

and

disassemble

the

oil level glass assembly (15) as follows:

a. Use

one

of

the

following

three

methods

to

remove

the

oil level glass assembly

from

the

coupl

ing

housing (11).

Method

(1) - Unscrew

the

assembly using

an

adjustable

spanner

which

has

the

correct

pin loca-

tions

to

match

the

two

holes

in

the

assembly.

or

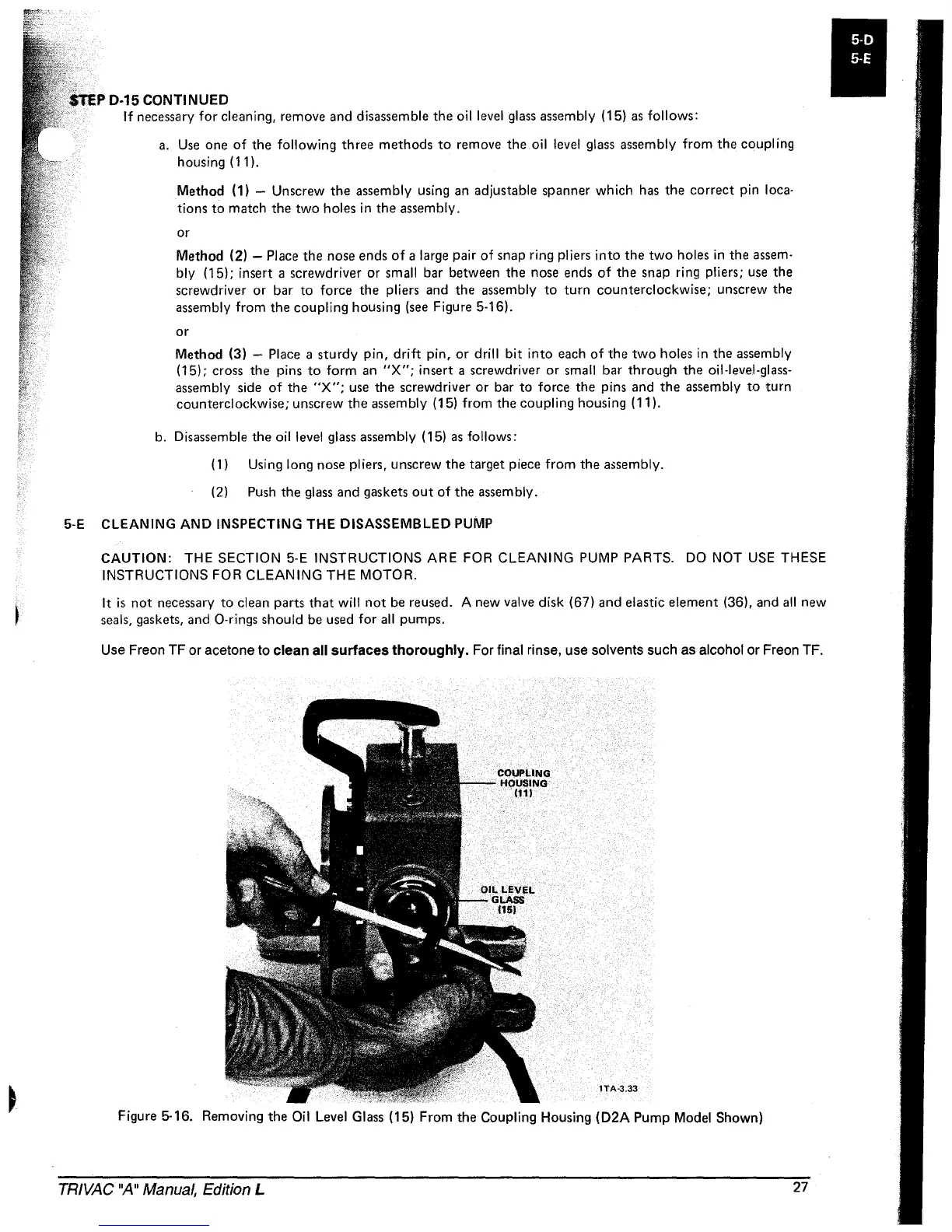

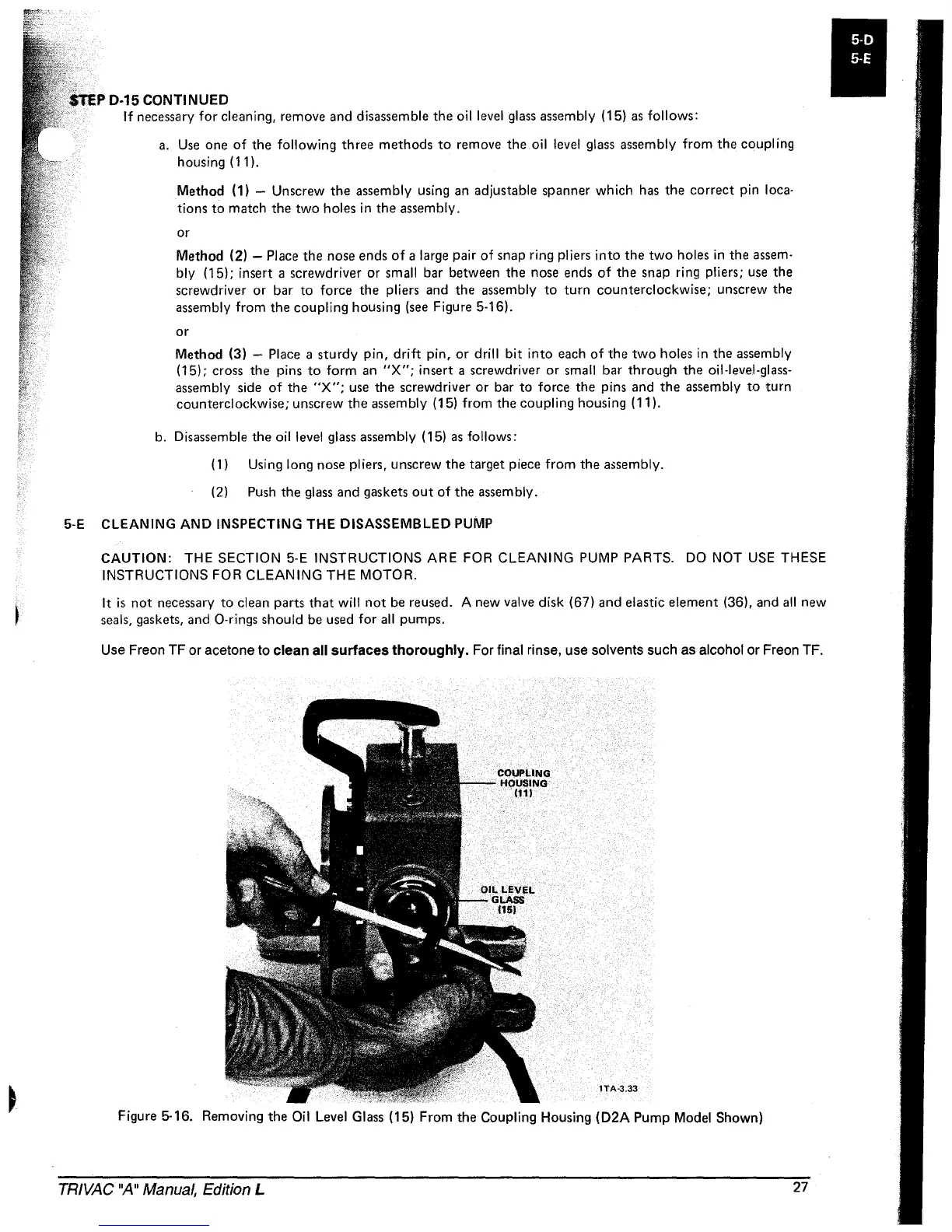

Method

(2) - Place

the

nose

ends

of

a large pair

of

snap

ring pliers

into

the

two

holes in

the

assem-

bly

(15);

insert a

screwdriver

or

small bar

between

the

nose

ends

of

the

snap

ring pliers; use

the

screwdriver

or

bar

to

force

the

pliers

and

the

assembly

to

turn

counterclockwise;

unscrew

the

assembly

from

the

coupling

hOUsing (see Figure 5-16).

or

Method

(3) - Place a

sturdy

pin,

drift

pin,

or

drill

bit

into

each

of

the

two

holes in

the

assembly

(15);

cross

the

pins

to

form

an

"X";

insert

a screwdriver

or

small

bar

through

the

oil-Ievel-glass-

assembly side

of

the

"X";

use

the

screwdriver

or

bar

to

force

the

pins

and

the

assembly

to

turn

counterclockwise;

unscrew

the

assembly (15)

from

the

coupling

housing

(11).

b. Disassemble

the

oil level glass assembly (15) as follows:

(1) Using long

nose

pliers,

unscrew

the

target

piece

from

the

assembly.

(2) Push

the

glass

and

gaskets

out

of

the

assembly.

5-E

CLEANING

AND

INSPECTING

THE

DISASSEMBLED PUMP

CAUTION:

THE

SECTION

5-E

INSTRUCTIONS

ARE

FOR

CLEANING

PUMP

PARTS.

DO NOT USE THESE

INSTRUCTIONS

FOR

CLEANING

THE

MOTOR.

It

is

not

necessary

to

clean

parts

that

will

not

be reused. A new valve disk (67)

and

elastic

element

(36),

and

all

new

seals, gaskets,

and

O-rings

should

be

used

for

all

pumps.

Use

Freon

TF

or

acetone

to

clean all surfaces thoroughly. For final

rinse,

use

solvents

such

as

alcohol

or

Freon

TF.

lTA-3.33

Figure 5-16. Removing

the

Oil Level Glass (15)

From

the

Coupling Housing

(D2A

Pump

Model

Shown)

TRIVAC "A" Manual, Edition L

27

Loading...

Loading...