42

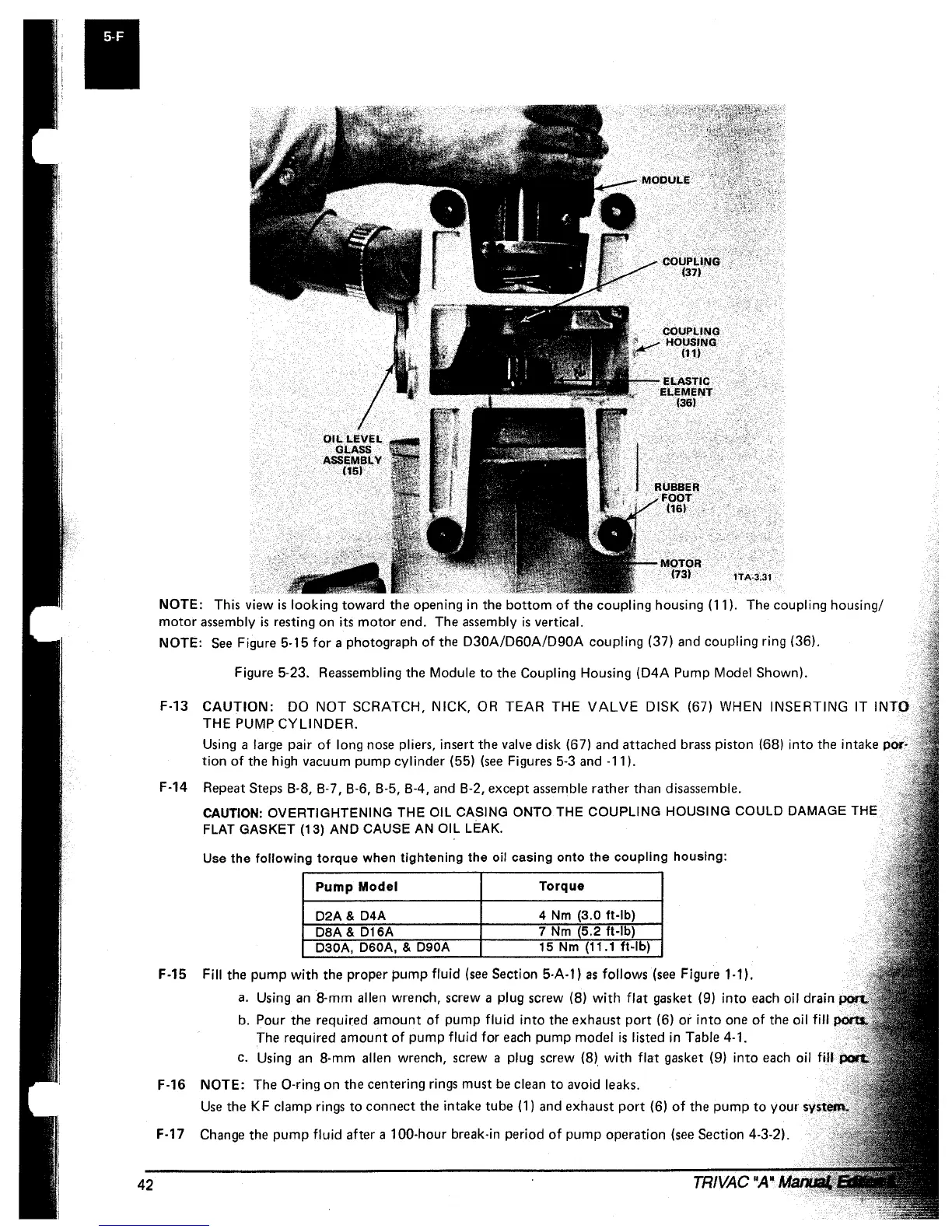

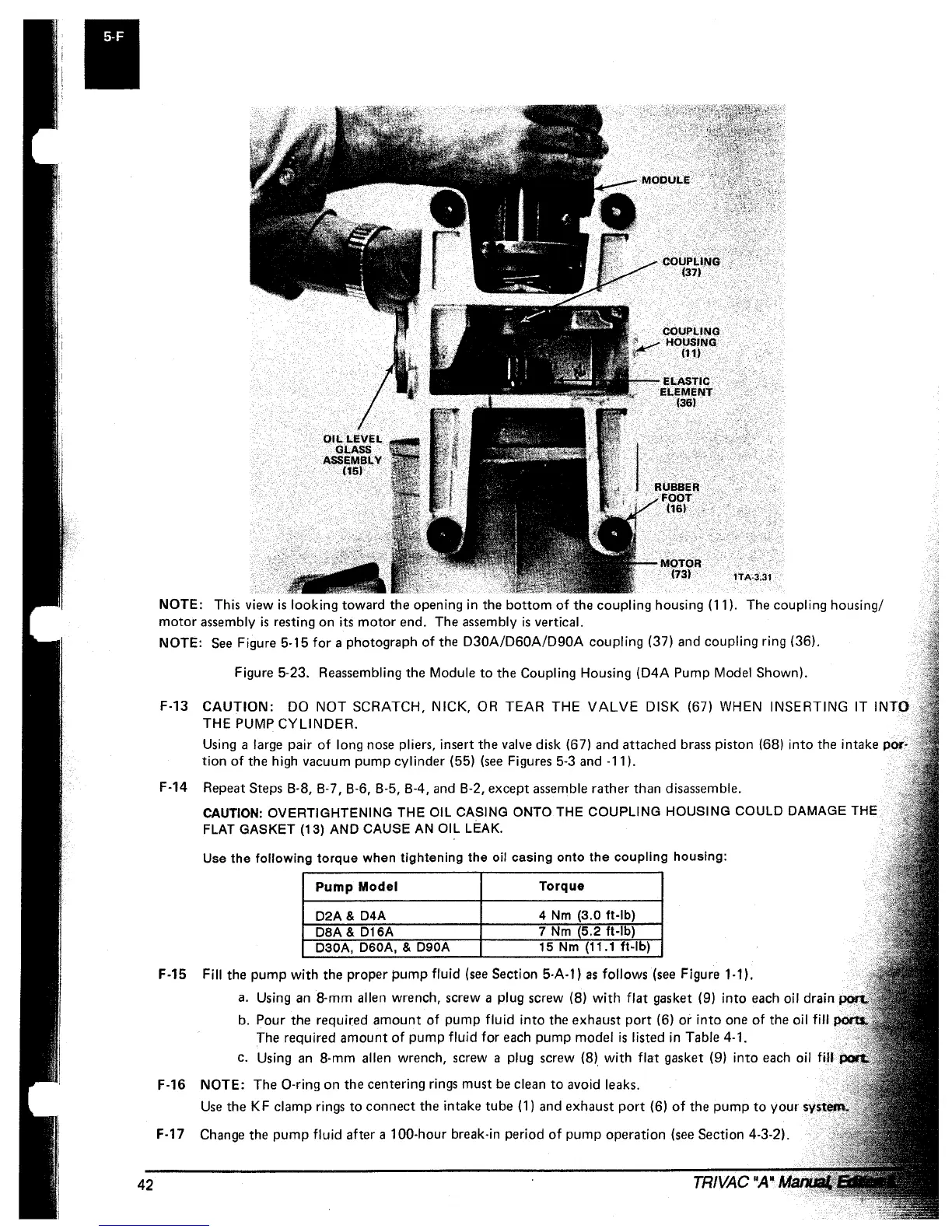

NOTE: This view

is

looking

toward the opening in the

bottom

of

the coupling housing (11). The coupling housing/

motor

assembly

is

resting on its

motor

end. The assembly

is

vertical.

NOTE:

See

Figure 5-15

for

a photograph

of

the

D30A/D60A/D90A

coupling (37) and coupling ring (36).

Figure 5-23. Reassembling the Module

to

the Coupling Housing

(D4A

Pump Model Shown).

F-13

CAUTION:

DO

NOT

SCRATCH, NICK,

OR

TEAR

THE

VALVE

DISK (67) WHEN INSERTING

IT

INTO

THE PUMP

CYLINDER.

Using a large pair

of

long

nose

pliers, insert the

valve

disk (67) and attached

brass

piston (68)

into

the intake por-

tion

of

the high vacuum pump cylinder (55)

(see

Figures

5-3

and

-11).

F-14 Repeat

Steps 8-8, 8-7, 8-6, 8-5, 8-4,

and

8-2, except

assemble

rather than disassemble.

CAUTION: OVERTIGHTENING THE OIL CASING ONTO THE COUPLING HOUSING COULD DAMAGE THE

FLAT

GASKET (13) AND CAUSE AN OIL LEAK.

Use

the

following

torque

when

tightening

the

oil

casing

onto

the

coupling

housing:

Pump

Model

Torque

D2A & D4A

4

Nm

(3.0 ft-Ib)

DBA & D16A

7

Nm

(5.2 ft-Ib)

D30A, D60A,

& D90A

15

Nm

(11.1

ft·lb)

F-15 Fill the pump

with

the proper pump

fluid

(see

Section

5-A-l)

as

follows

(see

Figure

1-11.

a.

Using

an

8-mm allen wrench, screw a plug screw (8)

with

flat

gasket (9)

into

each

oil drain

b. Pour the required amount

of

pump

fluid

into

the exhaust

port

(6)

or

into

one

of

the oil fill

The required amount

of

pump

fluid

for

each

pump model

is

listed in Table 4-1.

c.

Using

an

8-mm allen wrench, screw a plug screw (8)

with

flat

gasket (9)

into

each

oil fiU

F-16 NOTE:

The O-ring on the centering rings must

be

clean

to

avoid leaks.

Use

the

KF

clamp rings

to

connect the intake tube (1)

and

exhaust

port

(6)

of

the

pump

to

your

"v" ..... ;

...

F-17

Change

the

pump

fluid

after a 100-hour break-in period

of

pump operation

(see

Section 4-3-2).

Loading...

Loading...