120

MULTI V IV System Installation Manual

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

REFRIGERANT PIPING DESIGN

• Connect the end of the pipe to the branch pipes.

• Outdoor unit refrigerant pipes are divided at the end to connect to each indoor unit.

• Use flare connections for the indoor units, and braze connections for the outdoor pipes and branch pipes.

• Use a hexagon wrench to open and close the valve.

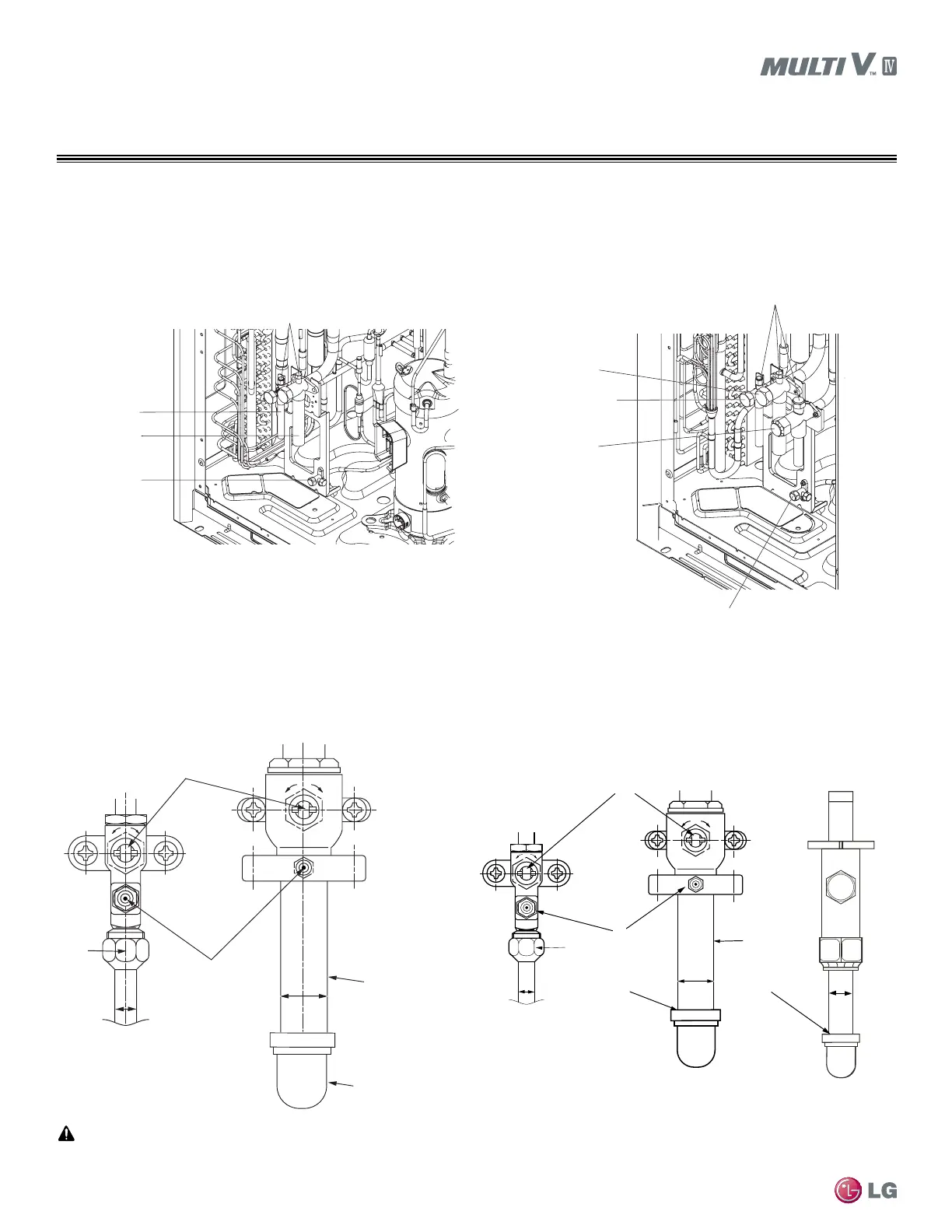

Figure 30: Heat Pump Outdoor Unit Valves.

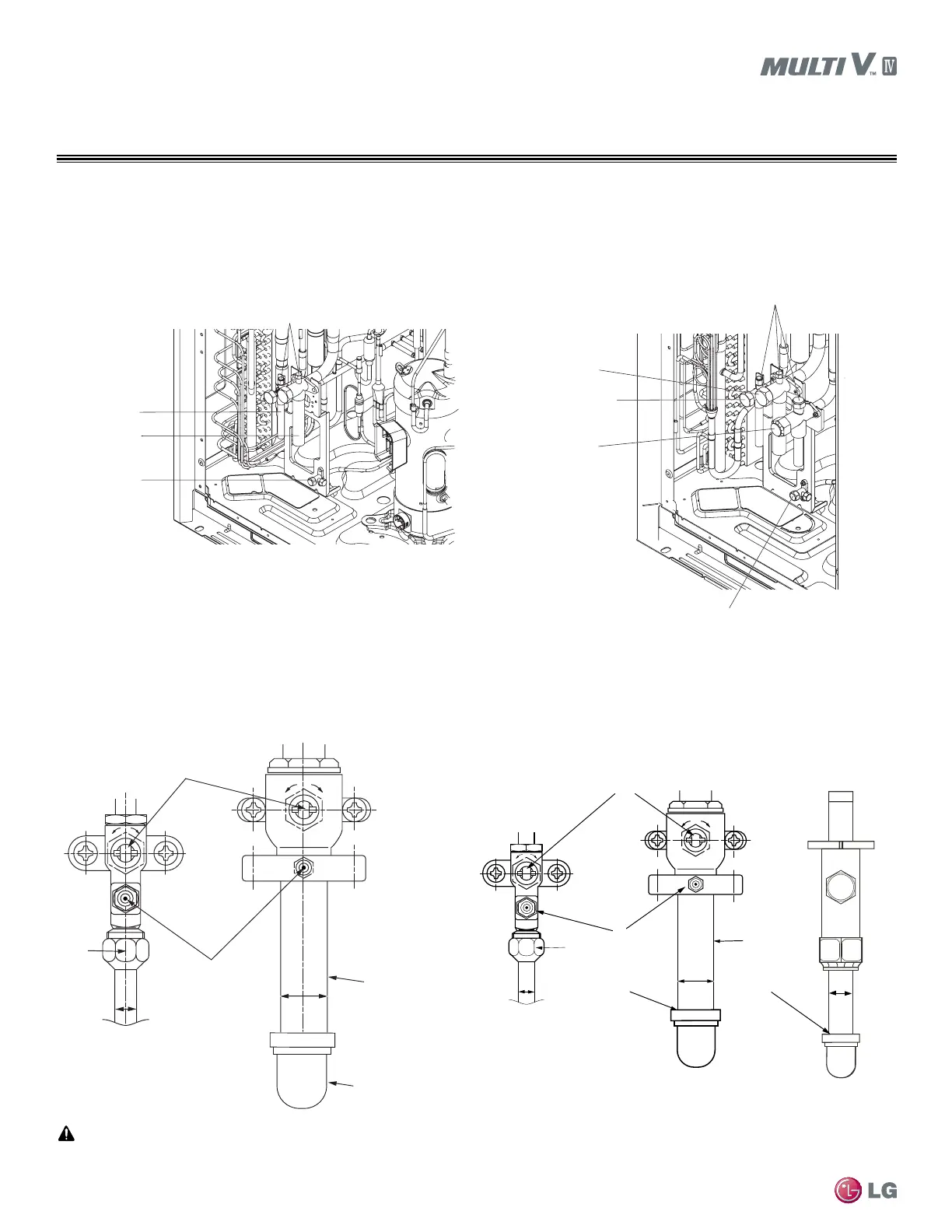

Figure 31: Heat Recovery

Outdoor Unit Valves.

Pipe Connections and Factory-supplied Shut-off Valve Operation

Vapor pipe

Service Port

Liquid pipe

Refrigerant

Charging Port

Service Port

Liquid pipe

Low Pressure

Vapor pipe

High Pressure

Vapor pipe

Refrigerant Charging Port

1. Field piping.

2. Flare nut.

3. Ball type service valves.

4. Schrader valves.

5. Liquid pipe.

6. Vapor pipe.

7. Field-supplied 90° elbow.

Heat Pump Unit Service / Schrader

Valve Detail

Heat Recovery Unit Service /

Schrader Valve Detail

Vapor Pipe Service Port

Liquid Pipe Service Port

2

5

4

3

1

6

7

Liquid Pipe

Service Valve

Low-pressure Vapor

Pipe Service Valve

High-pressure Vapor

Pipe Service Valve

1

2

5

8

3

6

4

78

1. Field piping.

2. Flare nut.

3. Ball type service valves.

4. Schrader valves.

5. Liquid pipe.

6. Low-pressure Vapor pipe.

7. High-pressure Vapor pipe

8. Field-supplied 90° elbow.

Do not expose the service valves of the outdoor unit to heat. Protect the service valve with a wet towel during brazing.

Loading...

Loading...