121

Installation

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Heat Pump Unit Connections

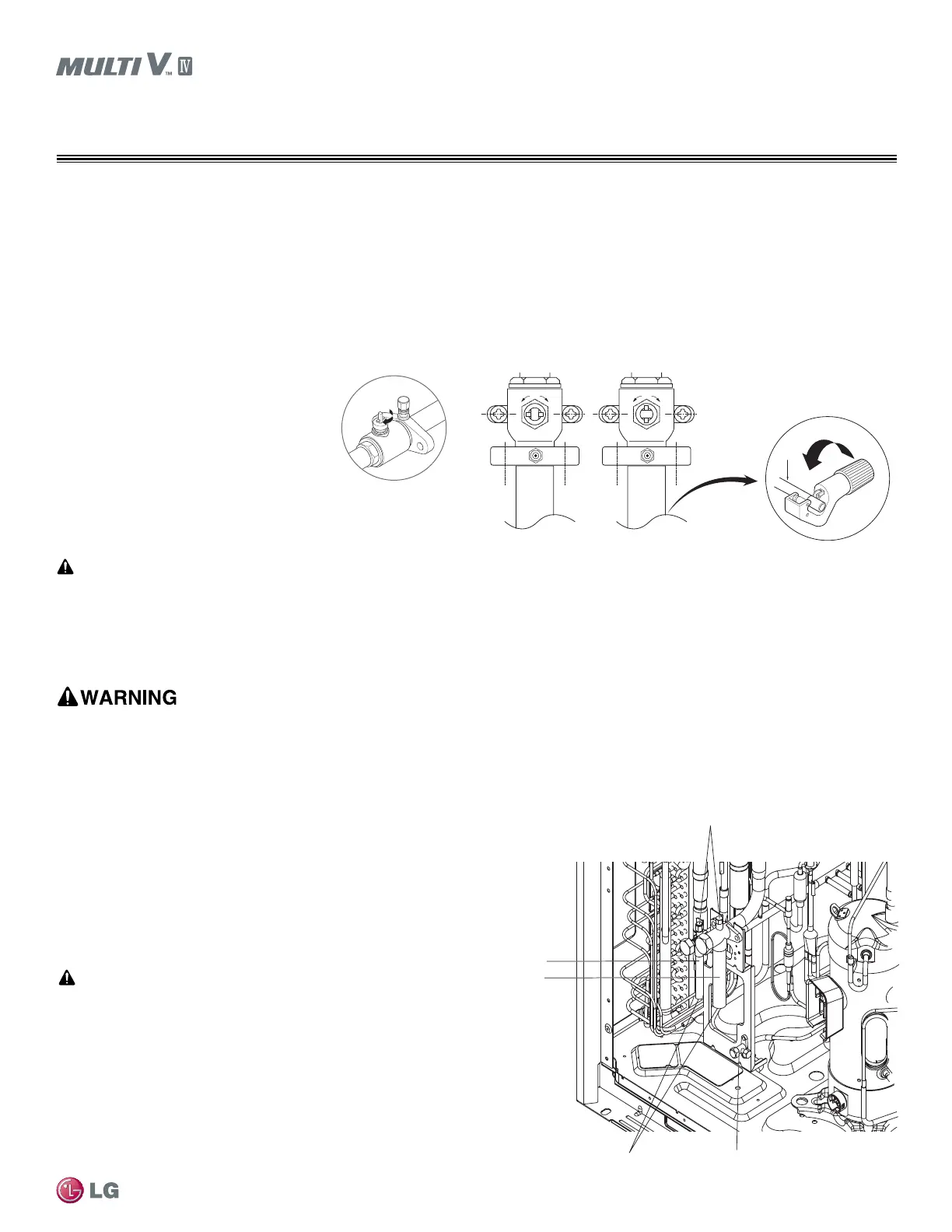

Gas pipe

Service Port

Liquid pipe

Leakage Prevention Cap

Refrigerant Charging Port

The leak-prevention cap attached to the outdoor unit service valves

must be removed before pipe installation.

1. Remove the leak-prevention cap.

2. Check if the liquid and vapor pipes are fully locked.

3. Vacuum out any remaining refrigerant or air through the service port.

Pipe Connections Between Outdoor Units and Indoor Units

REFRIGERANT PIPING DESIGN

Indicates “open” when the pipe and

the “flats” of the valve stem are parallel.

Cut length of pipe and valve as desired,

but length must be a minimum of 2-3/4 inches.

CLOSE OPEN

Figure 32: Service Valves - Open and Closed Positions.

Operating the Service Valves

1. Loosen or tighten the flare nut by using a torque wrench and backup wrench. Coat the flare connection with polyvinyl ether (PVE)

refrigeration oil.

2. Remove service valve cap. To operate the shutoff valve, turn ball valve stem 90° using an open-end wrench. Always backseat the valve.

After operation, always replace the caps (Tightening torque of service valve cap: =18.0 lb-ft).

3. Evacuate the system, and then charge the refrigerant using the Schrader valve. Reattach the Schrader valve cap after servicing is

complete. (Tightening torque of service cap: =10.0 lb-ft).

• When connecting the refrigerant piping, make sure the service valves of the outdoor unit are completely closed (factory setting). Do not open the service valves or attempt

to operate the system until the refrigerant pipe system installation has been completed. Never open the valves before a pressure test is performed, the system is evacu-

ated, a leak test performed, and the Commissioning Agent provides authorization to do so.

•

Do not use polyolester (POE) or any other type of mineral oil as a thread lubricant. If introduced to the refrigerant circuit,

will create oil sludge leading to system malfunction.

Use PVE (polyvinyl ether) type refrigeration oil only.

• Use steel wool or comparable material to ll gaps between the unit case and the refrigerant and electrical connections to prevent rodent and animal entry.

• The unit ships with a factory charge of

refrigerant. When connecting and braz-

ing the vapor line, protect the service

and Schrader valves from excessive

heat using a wet rag or cooling gel

product.

• After connections are complete, verify

that the service ports and caps are

securely tightened to prevent leaking

refrigerant gas.

• Always take extreme caution to prevent refrigerant gas (R410A) from leaking during use, around re or ame, and during brazing. If the refrigerant gas comes in contact

with a ame from any source, it may break down and generate a poisonous gas. Never braze in a room that is not ventilated. After refrigerant piping work is complete,

securely tighten both service and Schrader valves to help prevent refrigerant gas from leaking. Verify the system is free of leaks after refrigerant piping installation is

complete.

• Do not attempt to remove the service valve stem and packing or Shrader valve core. Physical injury or death may occur from the uncontrolled rapid release of refrigerant.

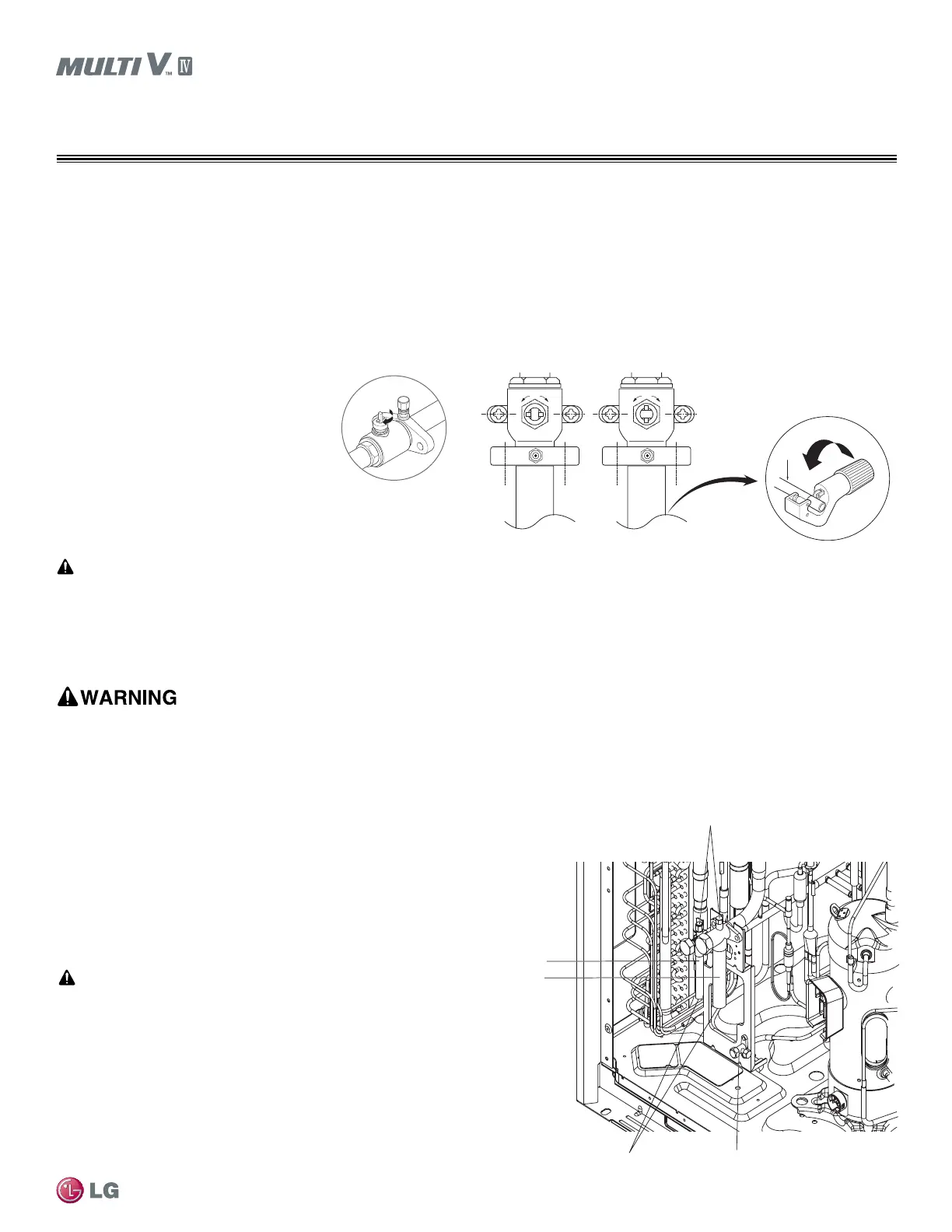

Figure 33: Interior View of

Heat Pump Unit.

Loading...

Loading...