99

Installation

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

REFRIGERANT PIPING DESIGN

System Engineering

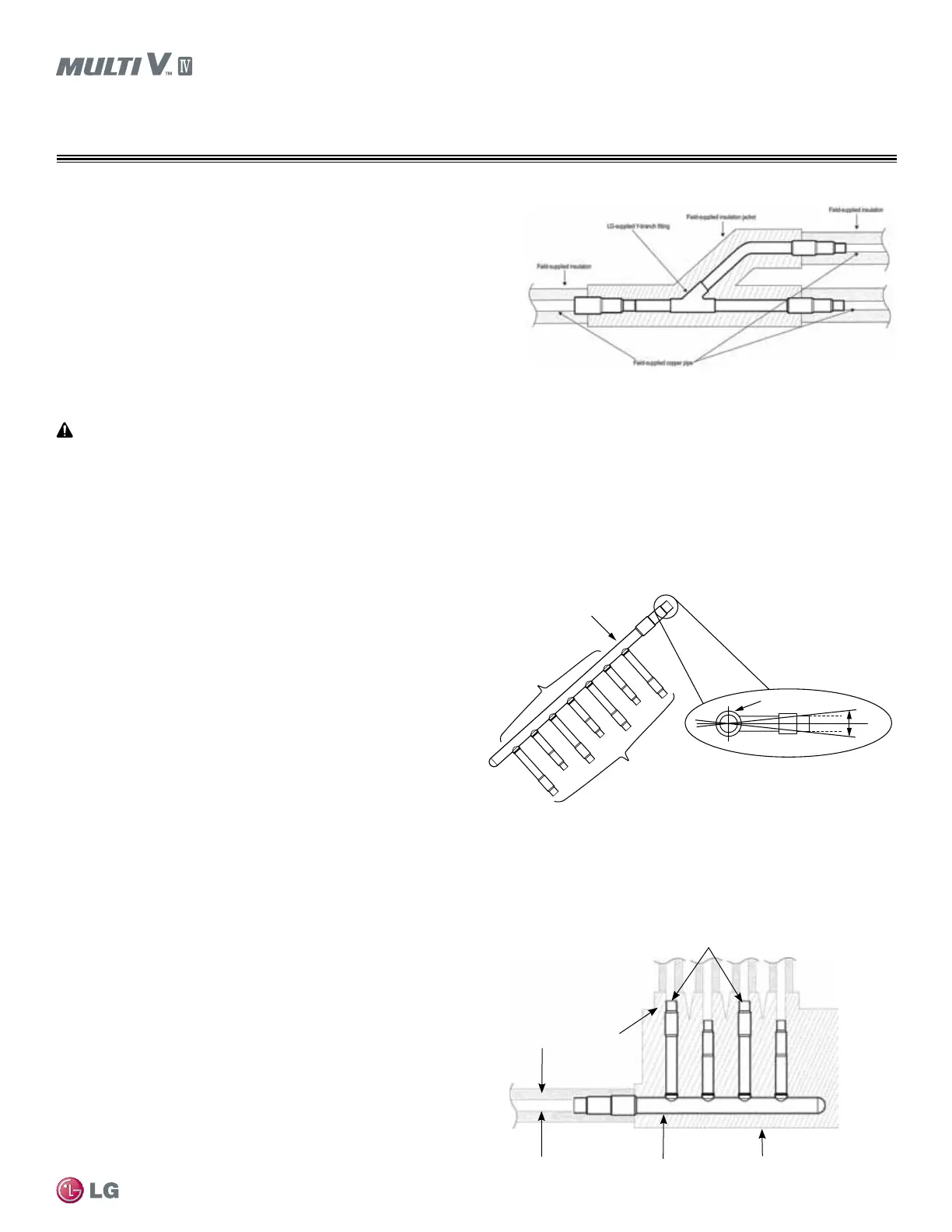

Figure 12: Y-branch Insulation and Pipe Detail.

Install Correctly

• Y-branches can be installed upstream between the Header and the outdoor unit, but a Y-branch cannot be installed between a header

and an indoor unit.

• To avoid the potential of uneven refrigerant distribution through a header fitting, minimize the difference in equivalent pipe length

between the header fitting and each connected indoor unit.

Header kits are intended for use where multiple indoor units are in

the same vicinity and it would be better to “home-run” the run-out

pipes back to a centralized location. If connecting multiple indoor

units that are far apart, Y-branches may be more economical. See

pages 39 or 79 for Header kit specifications and capacities.

Y-branches can be installed between the Header and the outdoor

unit, but a Y-branch cannot be installed between a Header and an

indoor unit. Headers must be installed in a horizontal and level

position with the distribution ports of the fitting in the same horizontal

plane as the straight-through branch.

When connecting indoor units to a Header, always connect the unit

with the largest nominal capacity to the port closest to the outdoor

unit. Then install the next largest indoor unit to the next port, working

down to the smallest indoor unit. Do not skip ports.

All indoor units must be mounted at an elevation below the Header fitting. All indoor units connected to a single Header fitting should be

located with an elevation difference between indoor units that does not exceed 49 feet. If indoor units are located at an elevation the same

as or above the Header fitting, do not use a Header. Instead, install a Y-branch fitting between the outdoor unit and the Header fitting, and

connect the elevated indoor unit to the Y-branch.

Header Insulation

Each Header kit comes with clam-shell type peel and stick insulation

jackets molded to fit the Header fittings—one for the liquid line and

one for the vapor line.

Header Kits

Y-branch Insulation

Each Y-branch kit comes with clam-shell type peel-and-stick insulation jackets

molded to t the Y-branch ttings—one for the liquid line, one for the vapor line.

• Check the t of the Y-branch clam-shell insulation jacket after the Y-branch is

installed.

• Mark the pipe where the insulation jacket ends.

• Remove the jacket.

• Install eld-provided insulation on the three (3) pipes rst.

• Peel the adhesive glue protector slip and install the clam-shell jacket over the

tting.

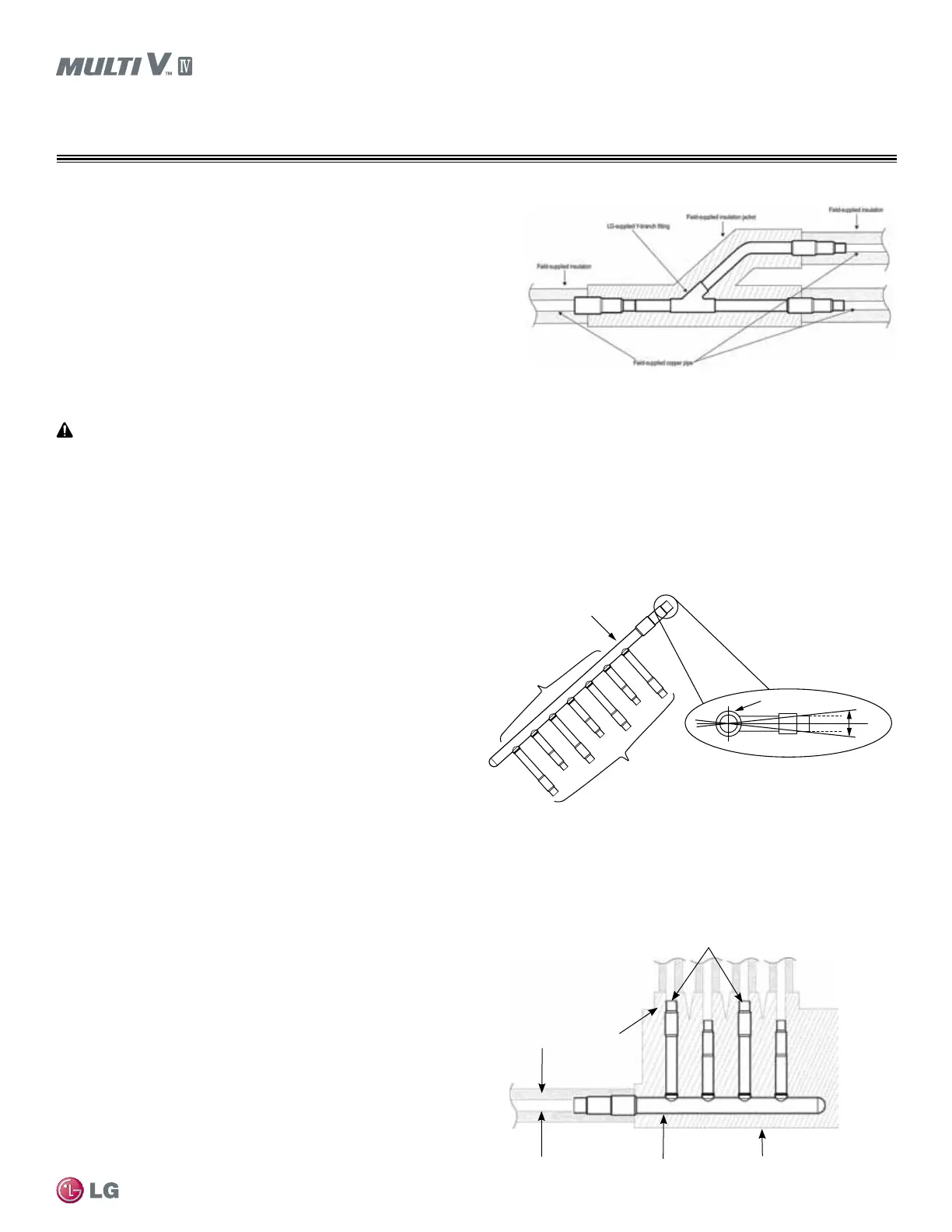

Figure 14: Header Insulation and Pipe Detail.

Figure 13: Header Kit—Horizontal Rotation Limit (Must be Installed Level

with No Rotation).

Smaller IDUs

Connect IDUs

Largest IDU

Header Inlet

Header End View

+0.0

-0.0

LG supplied insulation jacketLG supplied header

Field supplied copper pipe

Field supplied insulation

Field supplied copper pipe

Loading...

Loading...