Flare shape and flare nut tightening torque

Opening shutoff valve

Precautions when connecting pipes

- See the following table for flare part machining dimensions.

- When connecting the flare nuts, apply refrigerant oil to the inside and

outside of the flares and turn them three or four times at first. (Use

ester oil or ether oil.)

-

See the following table for tightening torque.(Applying too much torque may

cause the flares to crack.)

- After all the piping has been connected, use nitrogen to perform a

gas leak check.

1. Remove the cap and turn the valve counter clockwise with the hexa-

gon wrench.

2. Turn it until the shaft stops.

Do not apply excessive force to the shutoff valve. Doing so may

break the valve body, as the valve is not a backseat type. Always

use the special tool.

3. Make sure to tighten the cap securely.

CAUTION

• Always use a charge hose for service port connection.

• After tightening the cap, check that no refrigerant leaks are present.

• When loosening a flare nut, always use two wrenches in

combination, When connecting the piping,

always use a spanner and torque wrench

in combination to tighten the flare nut.

• When connecting a flare nut, coat the

flare(inner and outer faces) with oil for

R410A(PVE) and hand tighten the nut

3 to 4 turns as the initial tightening.

!

Insulation of shutoff valve

1. Use the heat insulation material for the refrigerant piping which has

an excellent heat-resistance (over 120 °C (248 °F)).

2. Precautions in high humidity circumstance:

This air conditioner has been tested according to the "ISO Conditions

with Mist" and confirmed that there is not any default. However, if it

is operated for a long time in high humid atmosphere (dew point

temperature: more than 23 °C (73 °F)), water drops are liable to fall.

In this case, add heat insulation material according to the following

procedure:

- EPDM (Ethylene Propylene Diene Methylene), NBR (Nitrile Butadi-

ene Rubber) – over 120 °C (248 °F) the heat-resistance tempera-

ture.

- Add the insulation over 10 mm (13/32 inch) thickness at high hu-

midity environment.

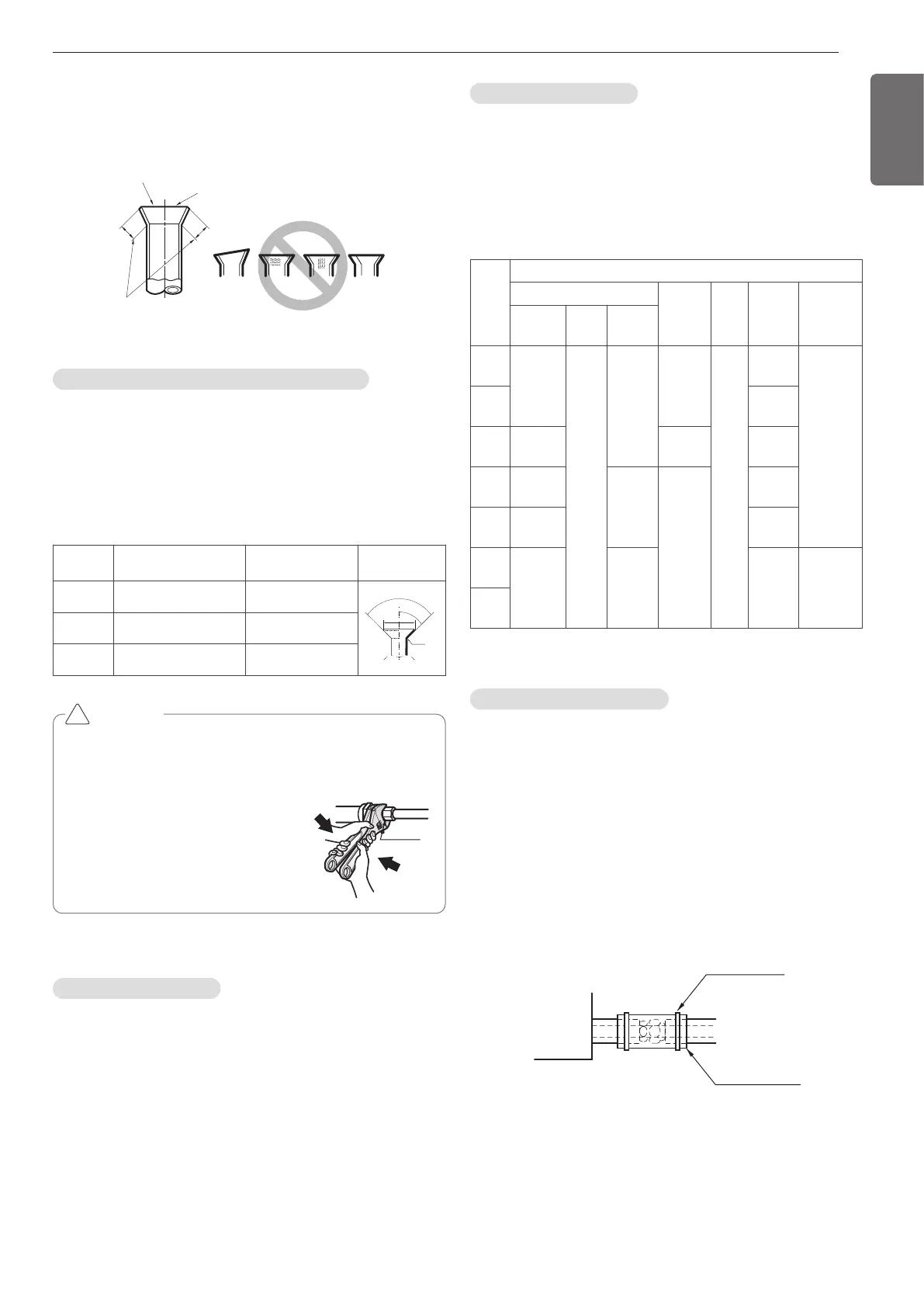

Closing shutoff valve

1. Remove the cap and turn the valve clockwise with the hexagon

wrench.

2. Securely tighten the valve until the shaft contacts the main body

seal.

3. Make sure to tighten the cap securely.

* For the tightening torque, refer to the table on the below.

Tightening torque

Shutoff

valve

size

Tightening torque (Turn clockwise to close) [N·m(lbf·ft)]

Shaft(valve body)

Cap

(Valve lid)

Service

port

Flare nut

Gas line pip-

ing attached

to unit

Closed Opend

Hexagonal

wrench

Ø6.35

(1/4)

6.0 (4.4)

±0.6 (0.44)

5.0(3.7)

±0.0

4mm

(0.16 inch)

17.6 (13.0)

±2.0 (1.5)

-

25.0 (18.4)

±2.5 (1.8)

-

Ø9.52

(3/8)

25.0 (18.4)

±2.5 (1.8)

Ø12.7

(1/2)

10.0 (7.4)

±1.0 (0.74)

20.0 (14.8)

±2.0 (1.5)

55 (40.6)

±6 (4.4)

Ø15.88

(5/8)

14.0 (10.3)

±1.4 (1.03)

5mm

(0.2 inch)

25.0 (18.4)

±2.5 (1.8)

75 (55.3)

±7 (5.16)

Ø19.05

(3/4)

14.0 (10.3)

±1.4 (1.03)

110 (81.1)

±10 (7.4)

Ø22.2

(7/8)

30.0 (22.1)

±3.0 (2.2)

8mm

(0.31 inch)

25.0 (18.4)

±3 (2.2)

Ø25.4

(11/8)

Pipe size

Tightening torque

[N·m(lbf·ft)]

A [mm(inch)] Flare shape

Ø9.52(3/8) 32.7(24.12)-39.9(29.43) 12.8(0.5)-13.2(0.52)

Loading...

Loading...