Hiflex

6 All Versions

English

2.5 - Version F

Freecooler units

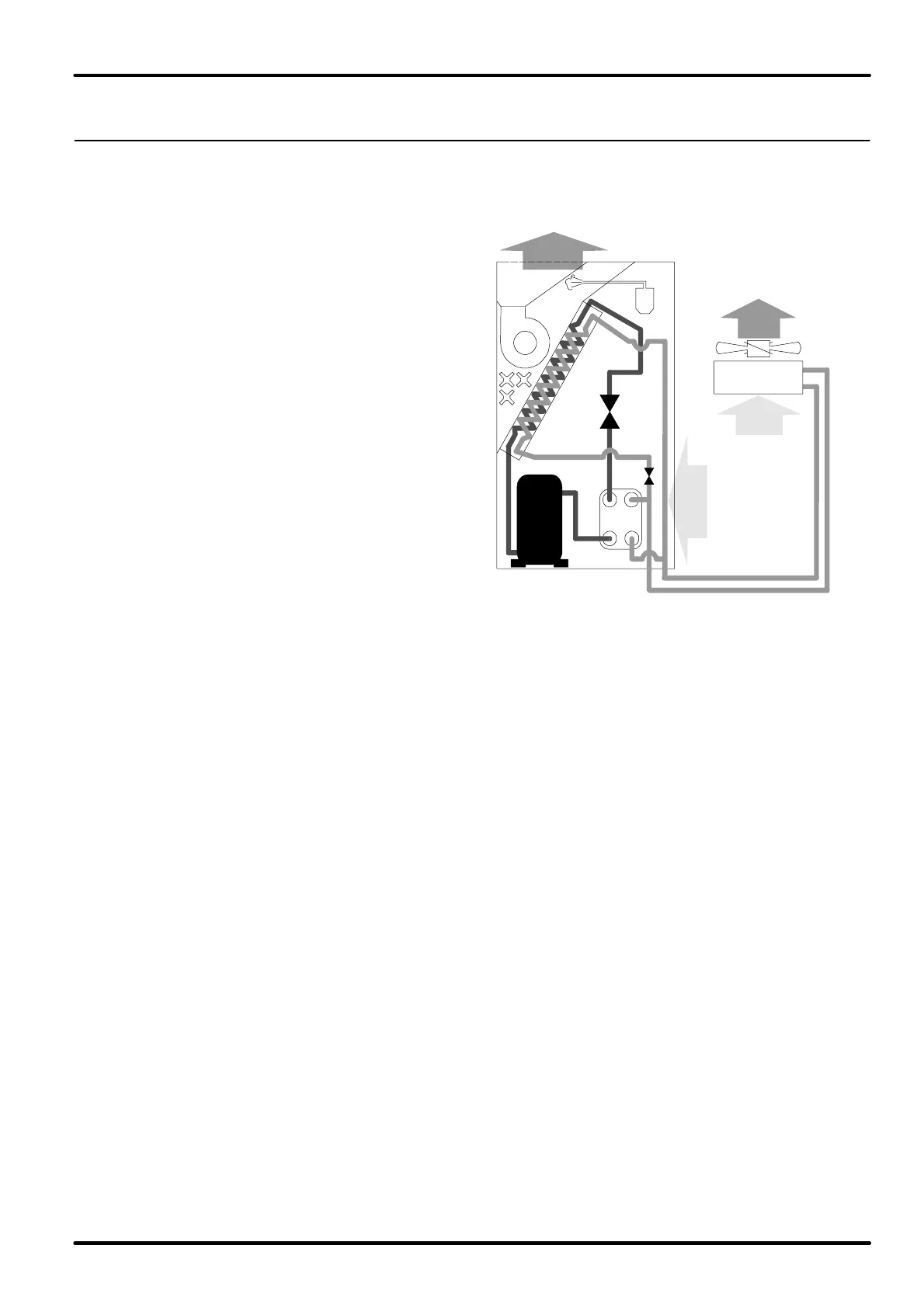

Refrigerating circuit

The 8 models are provided with a single re

frigerating circuit, the units 9 have two re

frigerating circuits. The refrigerating circuit

includes the compressor and the thermal

expansion valve with an external equalizer

controlling the refrigerant flow to the evapo

rator so as to keep a steady overheating de

gree. Before the thermal expansion valve

there is a sight glass enabling the visual

check of the refrigerant charge. A dryer fil

ter is installed in the liquid line for better

cleaning and less humidity in the circuit.

On-off valves are installed as standard to

help the extraordinary maintenance of the

circuits. A suitably sized safety valve is

installed after the condenser; the valve is

equipped with flanged connections to allow

the refrigerant to be discharged outside

through suitable pipes. All low temperature

parts of the refrigerating circuit are insu

lated. The refrigerating circuit is also pro

vided with a high pressure switch and a low

pressure switch. Il pressostato di minima è

a riarmo automatico, mentre, per ragioni di sicurezza derivanti dalle possibili alte pressioni nel compres

sore, il pressostato di massima è dotato di riarmo manuale. I valori di taratura dei pressostati sono indicati

nel manuale di installazione, fornito a bordo macchina.

The low pressure switch has automatic resetting, whereas - for safety reasons due to possible high pres

sure in the compressor - the high pressure switch has manual resetting. The pressure switch calibration

values are shown in the installation manual supplied with the machine.

Condenser

The units are provided with built-in stainless steel water condensers with braze-welded plates; this ad

vanced exchanger type gives the highest efficiency in heat exchange. In addition, a certain oversizing of

the exchanger has been provided so as to reduce pressure drops (and energy consumption of the water

pump) as much as possible and thus to allow the unit to operate with the external chiller in closed circuit,

even at high outdoor temperatures. The units shall operate with water in closed circuit with external chill

er. In the operation with closed circuit, the water is cooled by the outdoor air in a heat exchanger; in this

case, to avoid unwished ice formation during winter, it is advisable to obtain the mixture always with a gly

col percentage (refer to the installation manual for the suitable percentages). The circulation of the water-

glycol mixture is forced (the pump is not supplied). To minimize water consumption and the condensing

pressure check during the different seasons of the year, the unit is provided with a water register supplied

as standard on the machine.

Hydraulic circuit

The unit is provided with a 2-way modulating valve, complete with incremental motor for the water flow

control to the freecooling coil; the opening or closing signals, generated by the electronic control, manage

the valve in order to keep the ambient temperature at the required value.

Loading...

Loading...