Hiflex

3All Versions

English

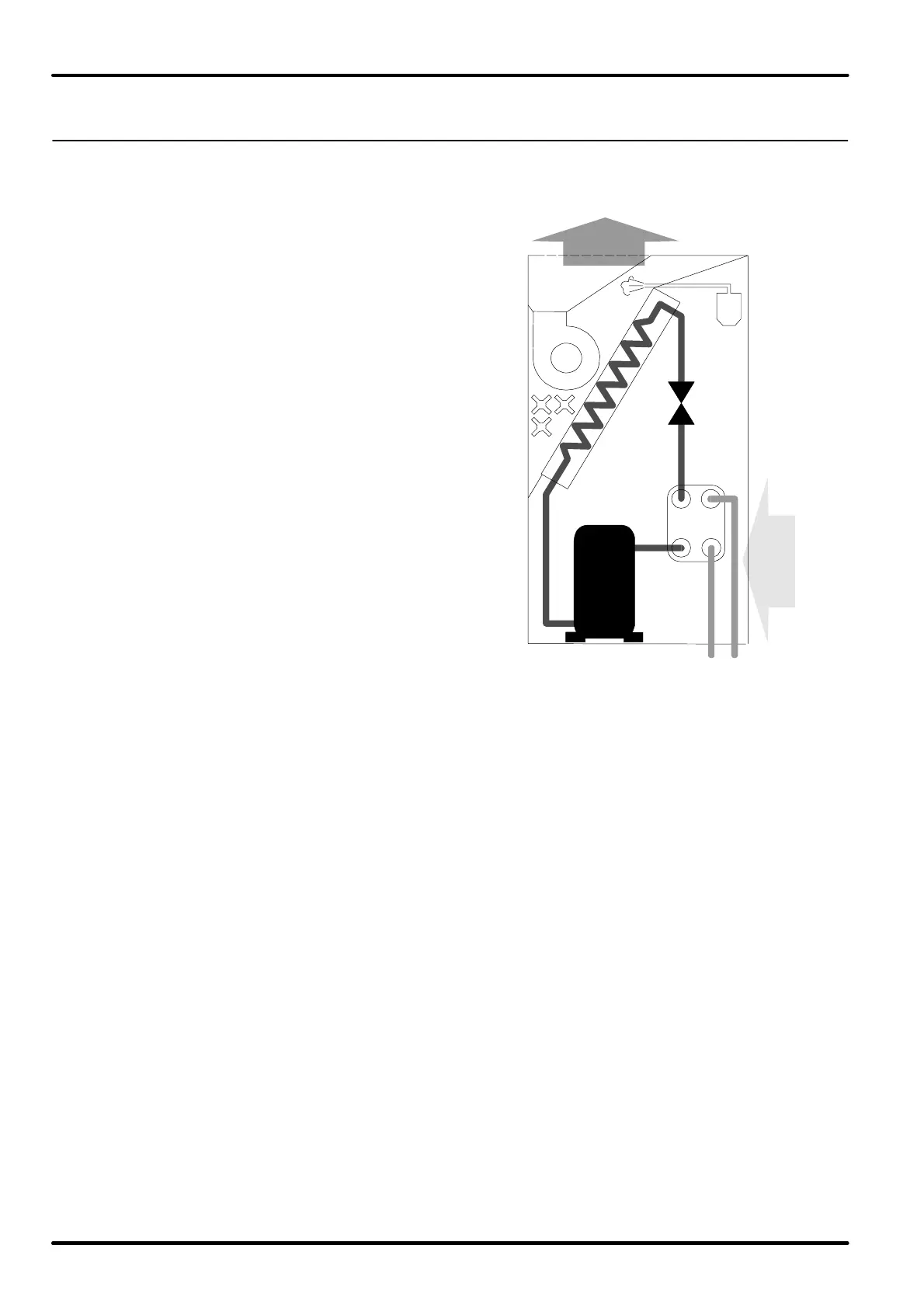

2.2 - Version W

Direct expansion water-condensed units

Refrigerating circuit

The 4-6-8 models are provided with a

single refrigerating circuit, the units

5-7-9 have two refrigerating circuits. The

refrigerating circuit includes the compres

sor and the thermal expansion valve with an

external equalizer controlling the refriger

ant flow to the evaporator so as to keep a

steady overheating degree. Before the

thermal expansion valve there is a sight

glass enabling the visual check of the re

frigerant charge. A dryer filter is installed in

the liquid line for better cleaning and less

humidity in the circuit. On-off valves are

installed as standard to help the extraordi

nary maintenance of the circuits.

A suitably sized safety valve is installed af

ter the condenser; the valve is equipped

with flanged connections to allow the refrig

erant to be discharged outside through

suitable pipes. All low temperature parts of

the refrigerating circuit are insulated. The

refrigerating circuit is also provided with a

high pressure switch and a low pressure

switch. The low pressure switch has auto

matic resetting, whereas - for safety rea

sons due to possible high pressure in the

compressor - the high pressure switch

has manual resetting. The pressure switch

calibration values are shown in the installa

tion manual supplied with the machine.

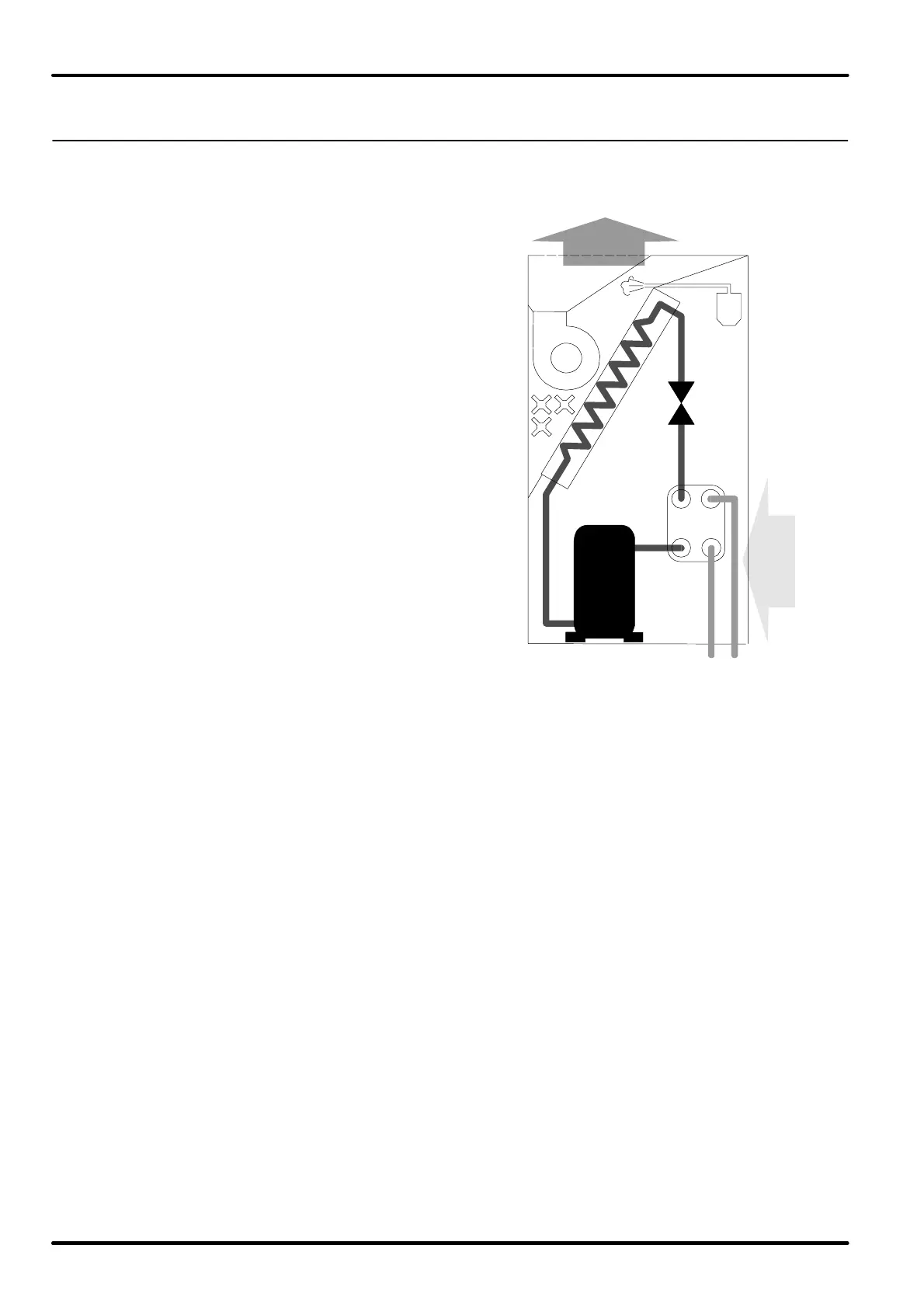

Condenser

The units are provided with a built-in stainless steel water condenser with braze-welded plates; this ad

vanced exchanger type gives the highest efficiency in heat exchange. In addition, a certain oversizing of

the exchanger has been provided so as to reduce pressure drops (and energy consumption of the water

pump) as much as possible and thus to allow the unit to operate with the external chiller in closed circuit,

even at high outdoor temperatures.

The units shall operate with throwaway water, tower water or water in closed circuit with external chill

er. In the operation with closed circuit, the water is cooled by the outdoor air in a heat exchanger; in this

case, to avoid unwished ice formation during winter, it is advisable to obtain the mixture always with a gly

col percentage (refer to the installation manual for the suitable percentages). The circulation of the water-

glycol mixture is forced (the pump is not supplied). If throwaway water or tower water is used, when instal

ling the unit fit a mechanical filter on the water line to protect the condenser against possible impurities

contained in the water (for the condenser cleaning see the installation manual).

Loading...

Loading...