Maintenance

WTR Installation & Maintenance Manual 330-15000 • Revision A • August5-2

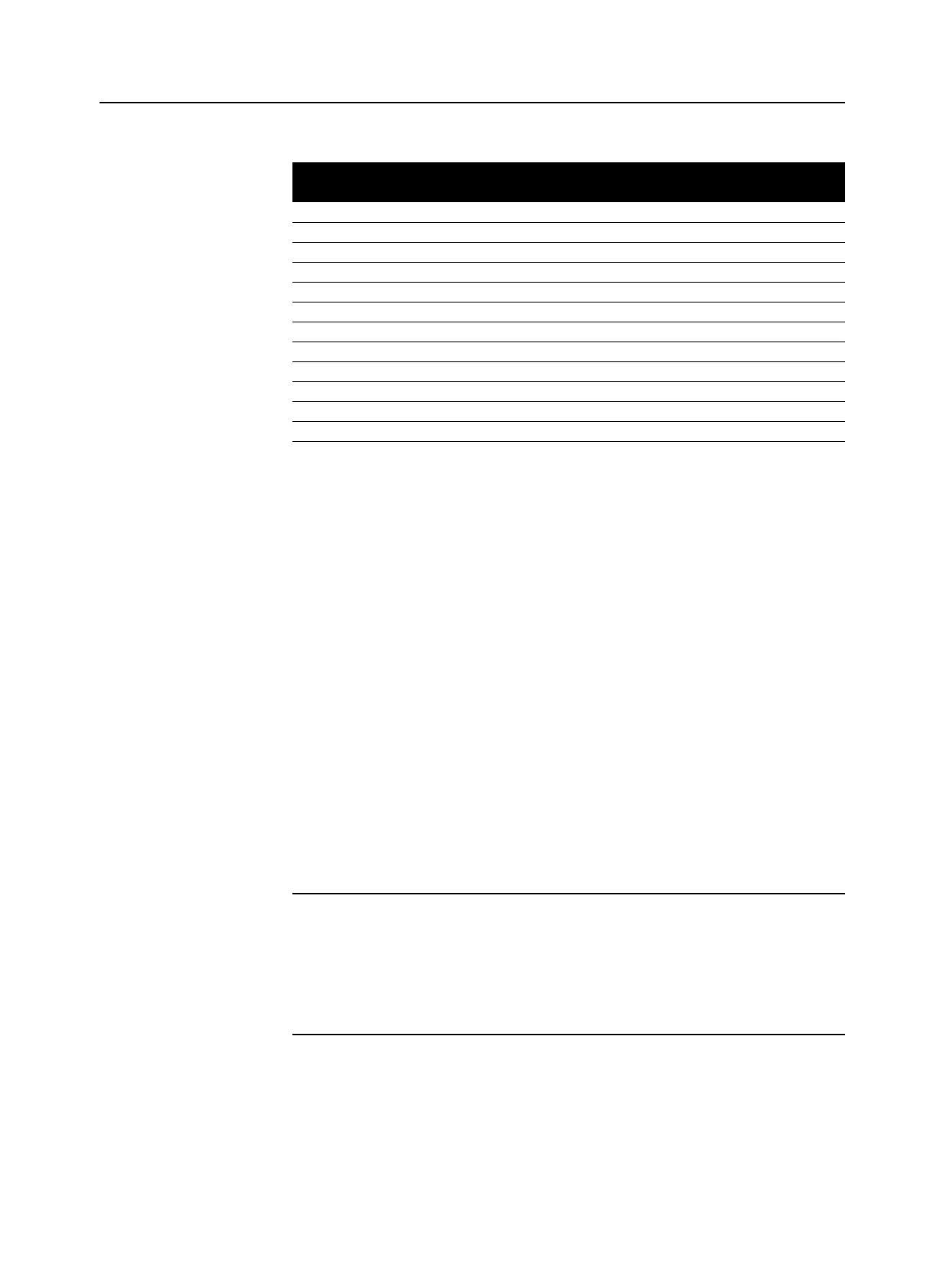

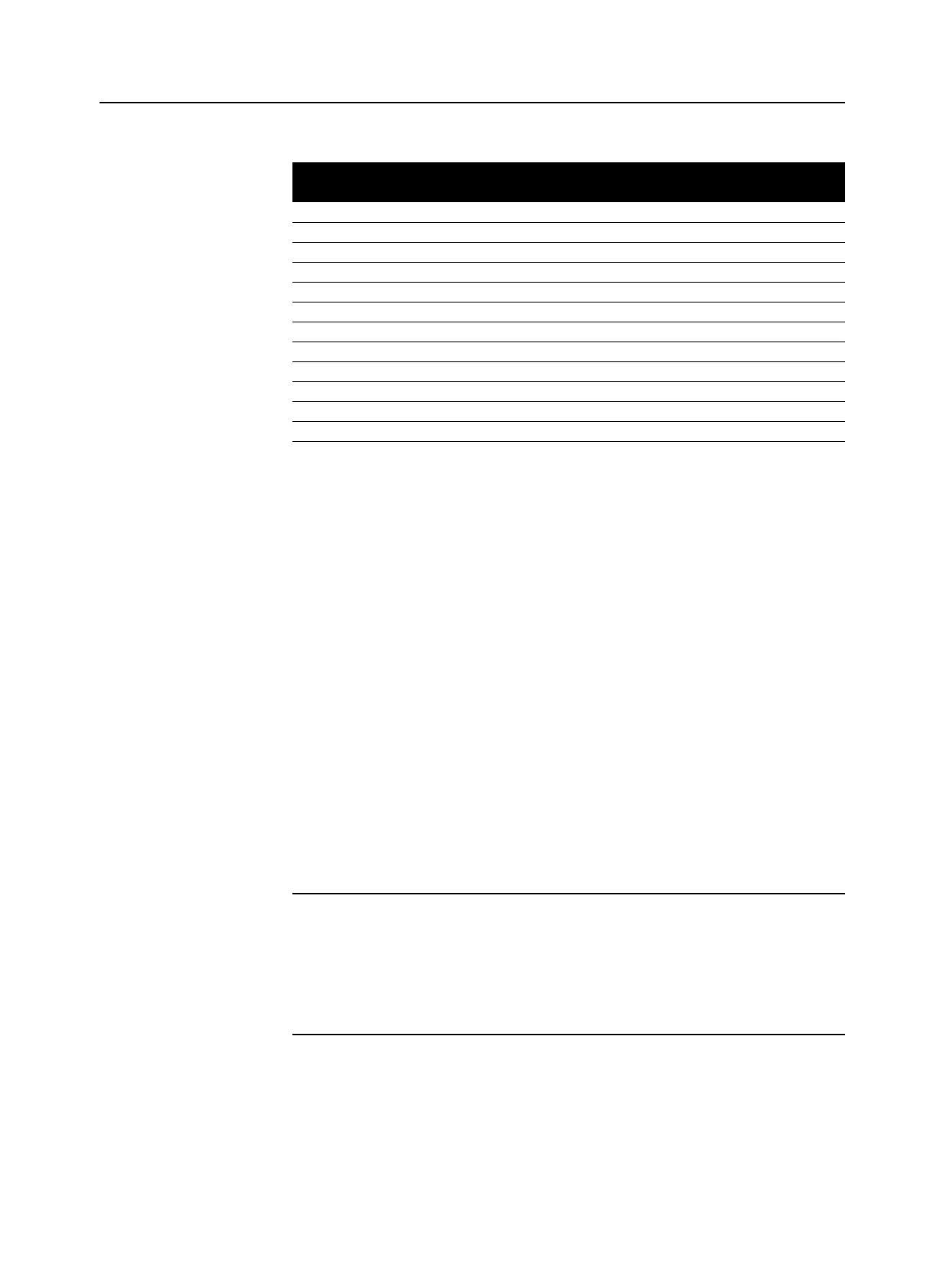

Table 5.2 – Lubricant Quantities

Amount of Lubricant Unit with SGA

Lbs Kg Lbs Kg

WTR-3 .75 .3 .5 .25

WTR-5 .75 .3 .5 .25

WTR-10/12 1.1 .5 .5 .25

WTR-15/21 1.3 .6 .5 .25

WTR-28/36 1.5 .7 .5 .25

WTR-40/48 1.7 .8 .5 .25

WTR-60/72 2.2 1 .5 .25

WTR-130/150 4 1.8 .5 .25

WTR-430 7.0 3.2 8.0 3.6

WTR-450 9.5 4.3 11.0 5.0

WTR-500 10.0 4.5 12.5 5.6

WTR-575 11.0 5.0 13.0 5.9

5.2 Minimum Lubricant Qualities Required

The standard lubricants used by Limitorque have been proven to be extremely reliable over

years of service. Limitorque does not recommend a particular lubricant substitute for the

standard lubricants; however, Limitorque does require the following lubricant qualities as a

minimum.

The lubricant must

• Contain an “EP” additive.

• Be suitable for the temperature range intended.

• Be water and heat resistant and non-separating.

• Not create more than 8% swell in Buna N or Viton.

• Not contain any grit, abrasive, or fillers.

• Be slump-resistant; prefer NLGI-0 grade.

• Not be corrosive to steel gears, ball, or roller bearings.

• Have a dropping point above 316°F for temperature ranges of -20°F to +150°F (-28°C

to 65°C).

5.3 Disassemble and Reassemble

a WARNING: Possible Hazardous Voltage. If WTR is mounted on an electric actuator,

turn power OFF before disassembling the WTR to prevent accidental start-up while

disassembling.

a WARNING: Potential High Pressure Vessel. Before removing or disassembling your

actuator, ensure that the valve or other actuated device is isolated and is not under

pressure.

Loading...

Loading...