Lifting Column LC3 IC | 21

Input/Output Specification Comments

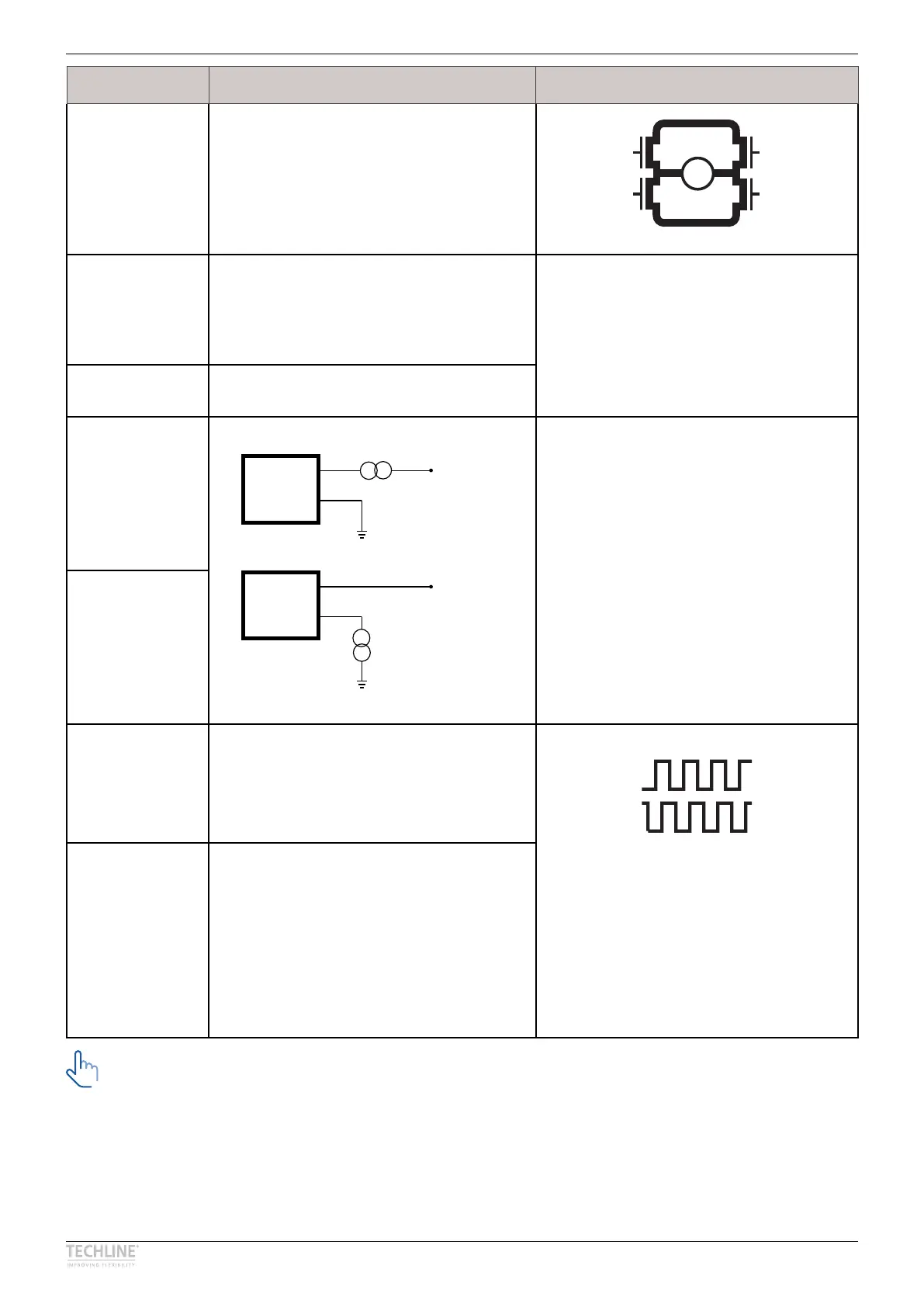

Description Easy to use interface with integrated

power electronics (H-bridge)�

The column is speed controlled by means

of a 4-20 mA signal�

Proportional provides a wide range of

possibilities for customisation�

H-Bridge

M

Brown 24 VDC + (VCC)

Connect Brown to positive

24 V ± 10 %

24 V, max� 20 A - current limit @ 20 A

Note: Do not change the power supply

polarity on the brown and blue wires!

Power supply GND (-) is electrically

connected to the housing

Blue 24 VDC - (GND)

Connect Blue to negative

Black 4-20 mA: Sinking current with reference to power

GND (blue)

Common mode voltage: GND to V supply

Equivalent input resistance ≈ 135 ohm

Overcurrent protected, reverse voltage

protected

The column comes with a 0 ms soft stop

See paragraph Proportional (speed)

control for more details

Red

Yellow Hall A

Movement per each Hall pulse:

20 mm Pitch -> 0�303 mm/count

Hall output (PNP)

The Hall sensor signals are generated

by the turning of the column gearing�

These signals can be fed into a PLC

(Programmable Logic Controller)� In the

PLC the quadrature signals can be used

to register the direction and position�

Output voltage min� V

IN

- 2 V Current

output 12 mA Overvoltage on the motor

can result in shorter pulses�

Green Hall B

Movement per each Hall pulse

20 mm Pitch -> 0�303 mm/count

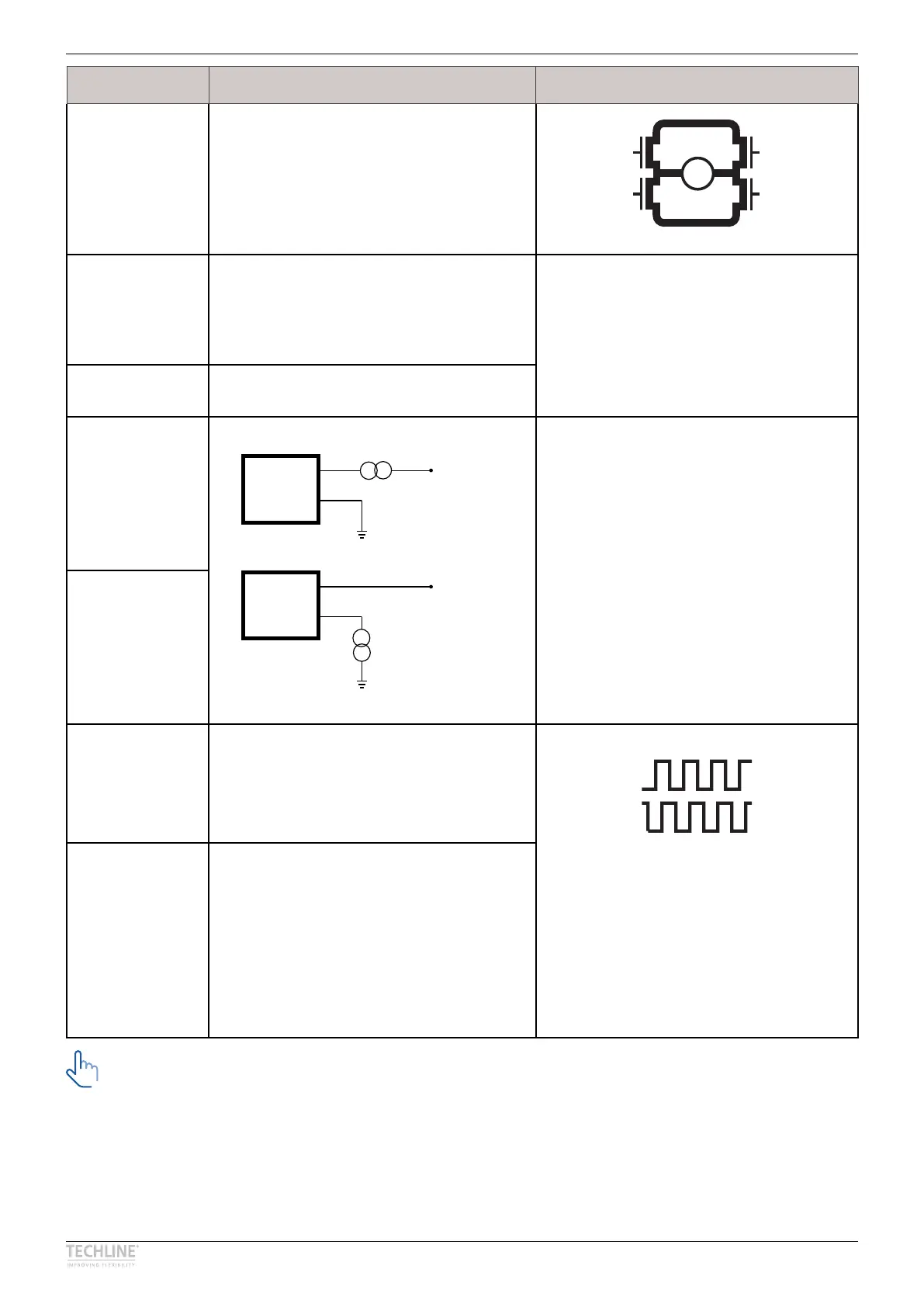

Prop

RED

BLACK

IN

V

Prop

RED

BLACK

IN

V

Current cut-offs should not be used as stop function! This might damage the column�

Current cut-offs should only be used in emergencies!

Current cut-off limits are not proportional with the load curves of the column� This means that the

current cut-offs cannot be used as load indicator�

There are tolerances on the spindle, nut, gear wheels etc� and these tolerances will have an influence

on the current consumption for the specific column�

Loading...

Loading...