Lifting Column LC3 IC | 10

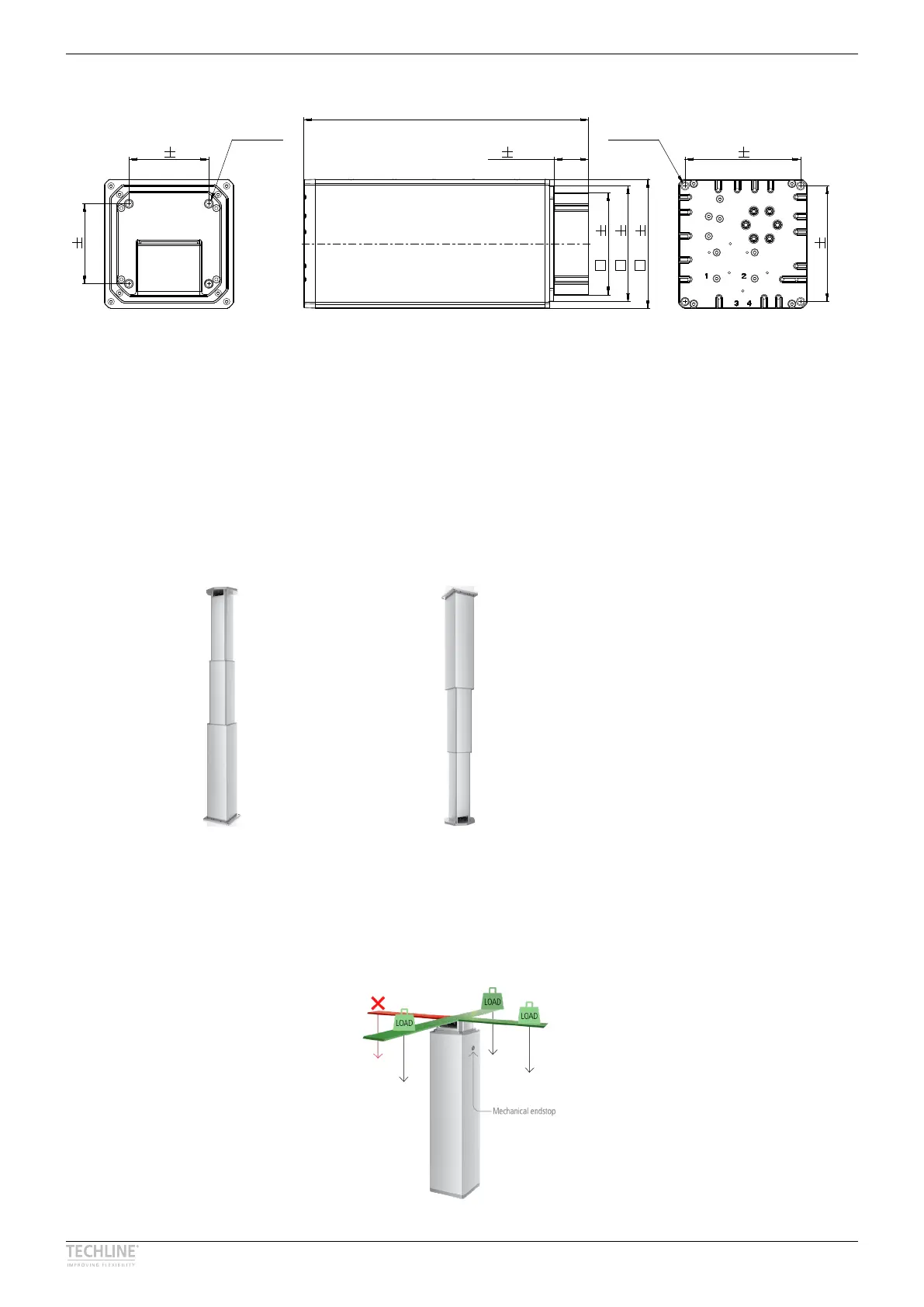

Built-in dimensions

146 0.5

146 0.5

101 0.5

101 0.5

43 0.5

163 1

129 1

146 1

4315

M10x1.5

30

M10

30

REP = STANDARD-SBU

B-B

SECTION A-A

MIN.90MIN.60

(M8) 146

(M6) 144 -146

(M5) 143 -146

(M4) 142 -146

M8

Drill-Max. 16

Thread-Max 14

M6

Drill-Max. 15

Thread-Max 13

M5

Drill-Max. 13

Thread-Max 11

M4

Drill-Max. 12

Thread-Max 10

½ S + 280mm

Created By Pamir Hamid 2022-07-07

Modified By Pamir Hamid 2022-07-11

SCALE : 1:5

Drawing No.: TEC-0001888

SECTION C-C

C

C

M10x1.5 M10x1.5

The minimum built-in dimension (BID) is 480 mm due to the design of the lifting column�

The tolerance for BID is +/- 1�5 mm

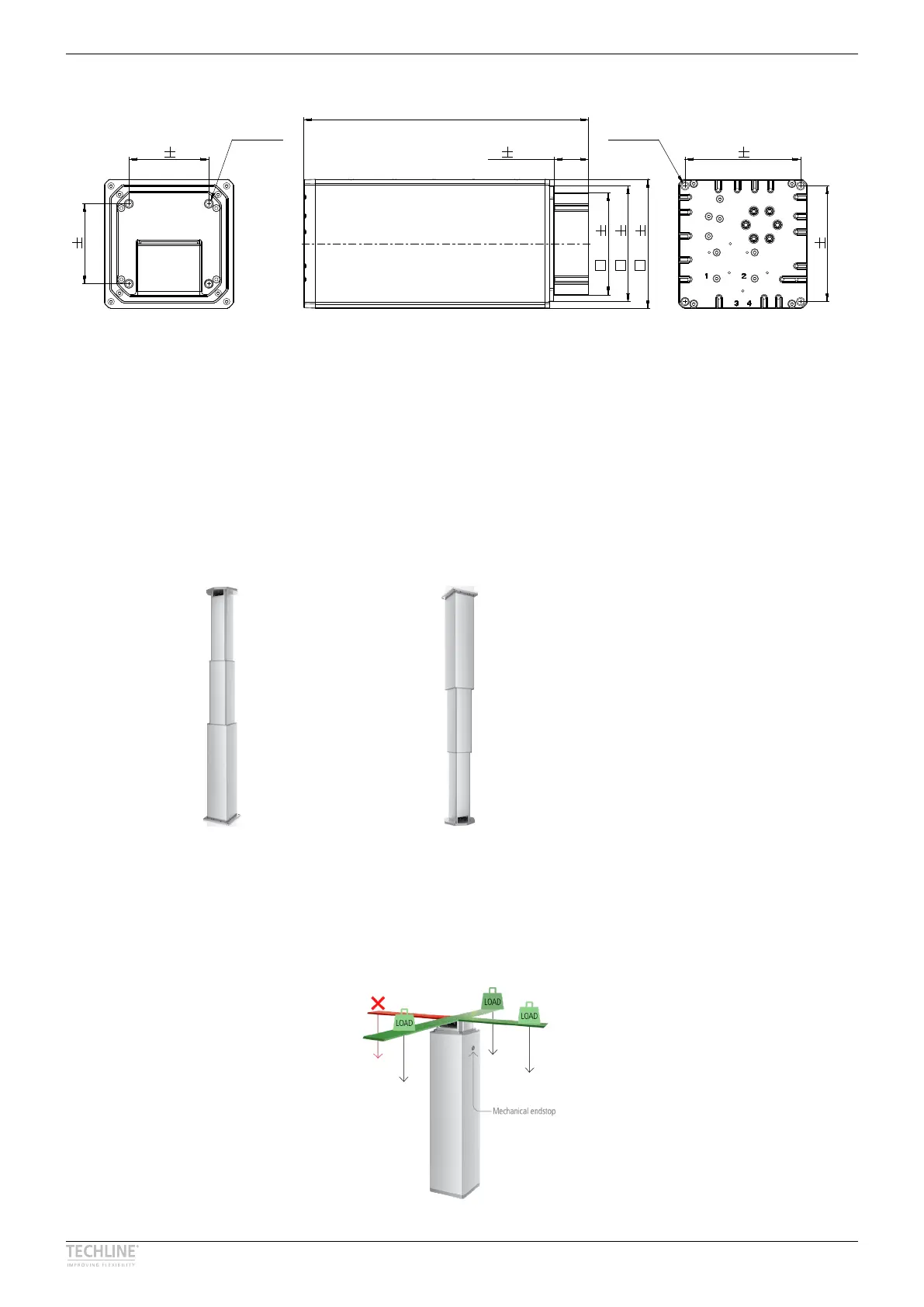

LC3 IC mounting guidelines

LC3 IC is for use in push applications and can be mounted in both directions – largest profile down or

largest profile up� The column can only be used for vertical movement -not for horizontal�

Top plate up Top plate down

Note: The cable outlet for motor connection is positioned at the top (smallest profile)

Mount the LC3 IC in the application using the 4x M10 mounting holes in both endplates�

If the column is to be used with a constant high off-center load, we recommend to install the constant

weight in one of the 3 ways illustrated by the green symbols� It is not recommended to install the weight on

the opposite side of the mechanical endstop as illustrated with the red symbol� This installation can create an

uneven movement and noise when the lifting column reaches the endstop position�

Loading...

Loading...