Glossary of Terms

Automated Lubrication System (ALS) – A pump supplies a number of bearings with lubricant via a

system of transmission lines and divider valves.

Closure Plug – A threaded plug used to purposely block lubricant from exiting a valve outlet. This

lubricant will move down to the next outlet.

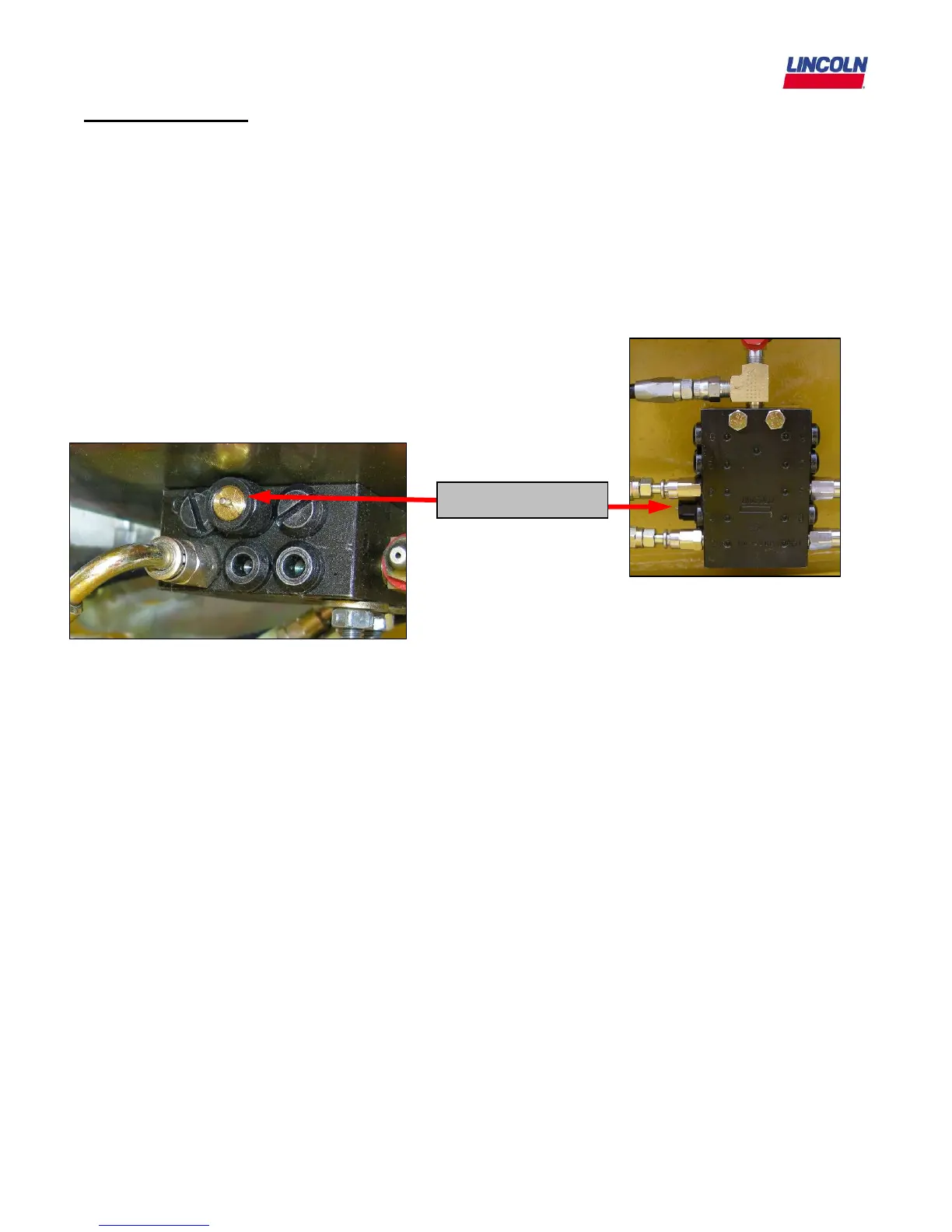

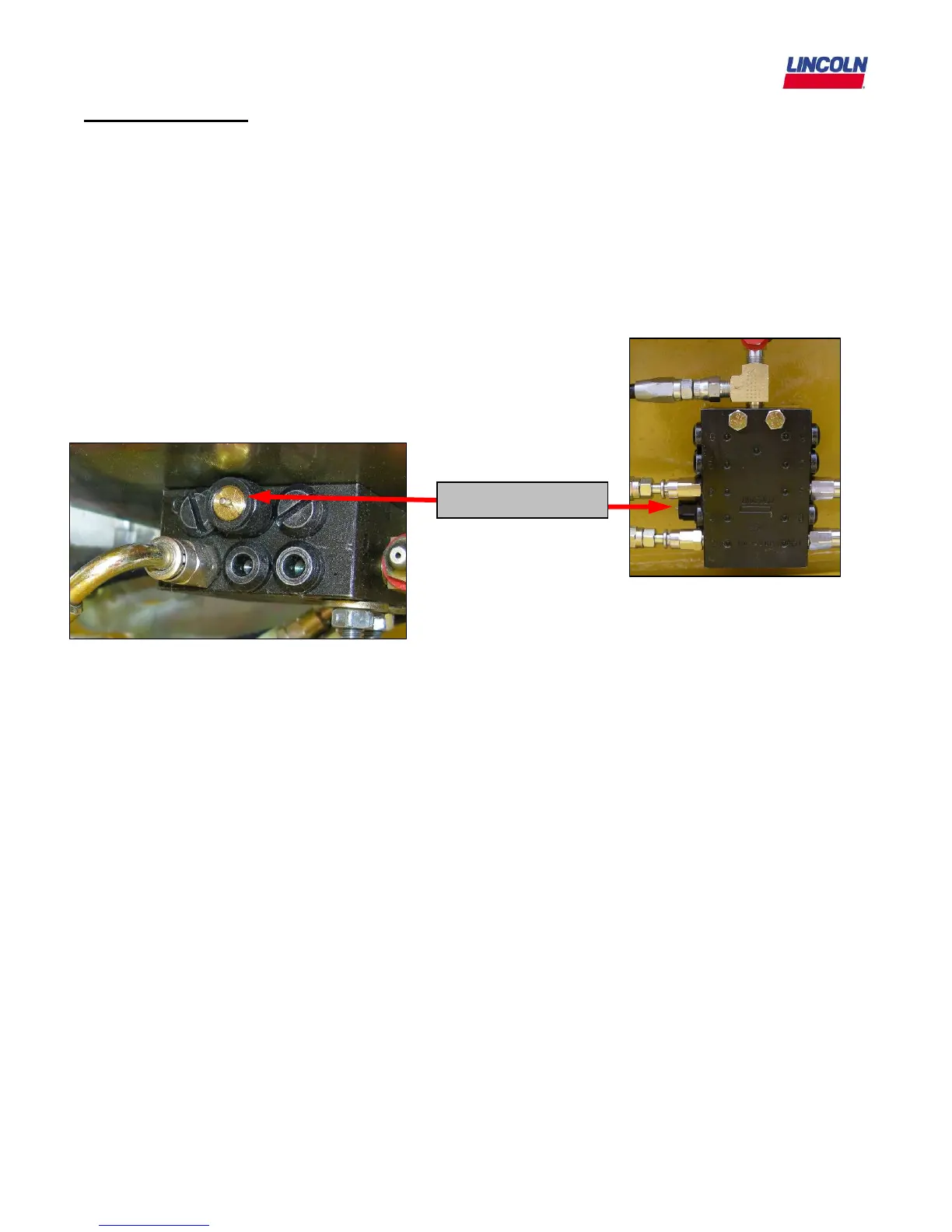

Cycle Indicator Pin – Visual indication pin attached to a valve piston on the divider valve (see below).

The pin is located on the side of the divider valve that moves in and out as grease flows within the

valve. A cycle indicator pin is not necessarily present on all divider valves. Divider valves without cycle

indicator pins are available.

Cycle Indicator Pin

Cycle Rate – Amount of time it takes for every valve to cycle at least once.

Distribution block – See divider valve

Divider Valve – A Quicklub

®

divider valve is a proportioning device consisting of a minimum of three

pistons. A primary divider valve is the first divider valve downstream from the lube pump. A secondary

divider valve is any divider valve receiving lubricant from the primary divider valve. (A.k.a. distribution

block, metering valve or SSV valve)

Feed Line – Tubing or hose going from a divider valve directly into a terminating lubrication fitting.

Fitting – Hardware used to connect hose or tube to lubrication port on equipment.

Lube Event – Depending on the Quicklub

®

pump that is used, it is the duration the pump is pumping

grease. On a monitored pump, the lube event duration is controlled by a proximity switch. On the non-

monitored pumps, the lube event duration is controlled by setting the “on” and “off” times via the dials

on the PC board.

Metering Valve – See divider valve.

Monitored Pump – A Quicklub

®

pump that utilizes a proximity switch to monitor and end the lube

event. The pump requires that the “off time” be set on the PC board, which is accessible from the front

side of the pump. The “off time” is the length of time between lube events (pump operation).

2/13/09

4

Loading...

Loading...