System Operation (Monitored System)

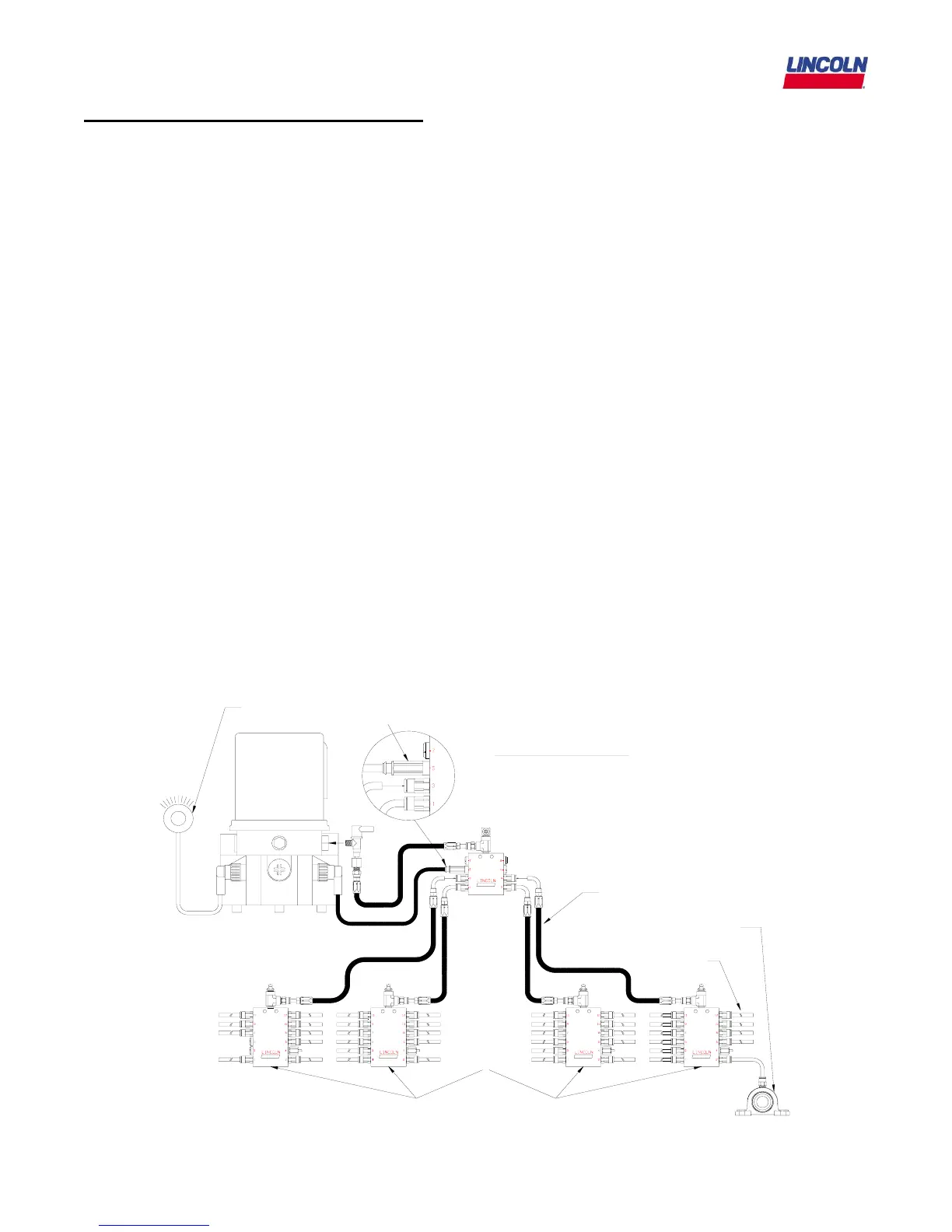

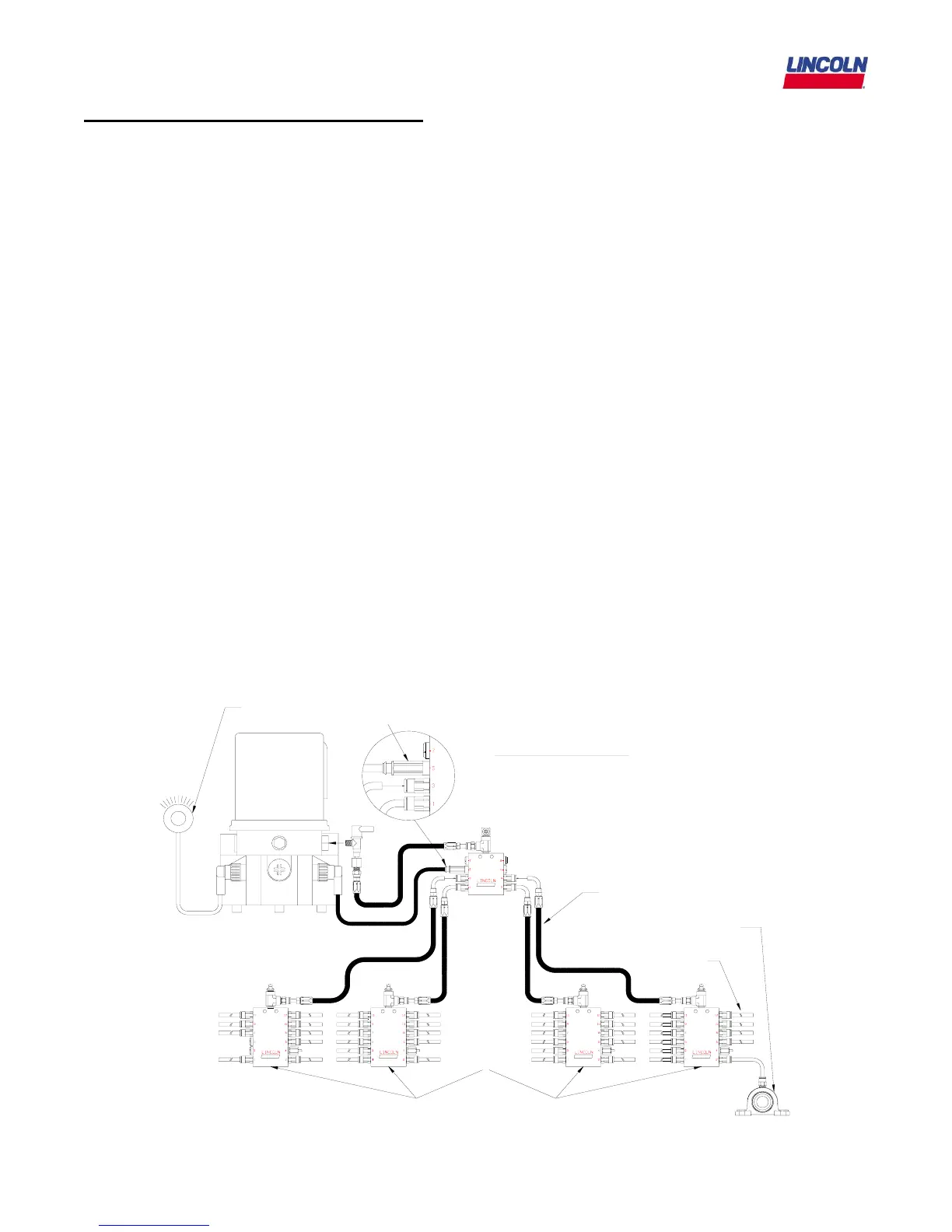

The key components of the Quicklub Monitored system are:

1. Pump with an Integrated Timer. The Integrated timer controls the “Off Time” of the pump.

2. Divider valve network consisting of a Primary Valve and Secondary Valves with attached Cycle

Indicator Pin.

3. A lubrication event is initiated by actuating the pump via the Integrated Timer based on a

preset “pause time” or time between lubrication events.

4. The Pump dispenses lubricant to the primary divider valve.

5. The Primary Valve distributes the lubricant to the secondary valves.

6. The Secondary Valves distribute and dispense lubricant to the lubrication points.

7. Lubricant flow through the divider valves actuates the Cycle Indicator Pin for a visual

inspection of proper operation.

8. The pump will run until the proximity switch reads one full cycle of the piston. The proximity

switch can be attached to any block outlet in the system.

9. The timer now begins countdown for the next lubrication event.

10. The Pushbutton/Fault light will blink if the pump reservoir is low on grease or if there is a

blockage in the system.

2/13/09

7

Primary

Divider

Valve

R3 Valve

Secondary

Divider

Valves

Pushbutton/

Fault Light

Pump

Proximity

Sensor

Hose

Monitored System

Lube Point

Hose

Loading...

Loading...