21

Controllers. LS. Load Sensing

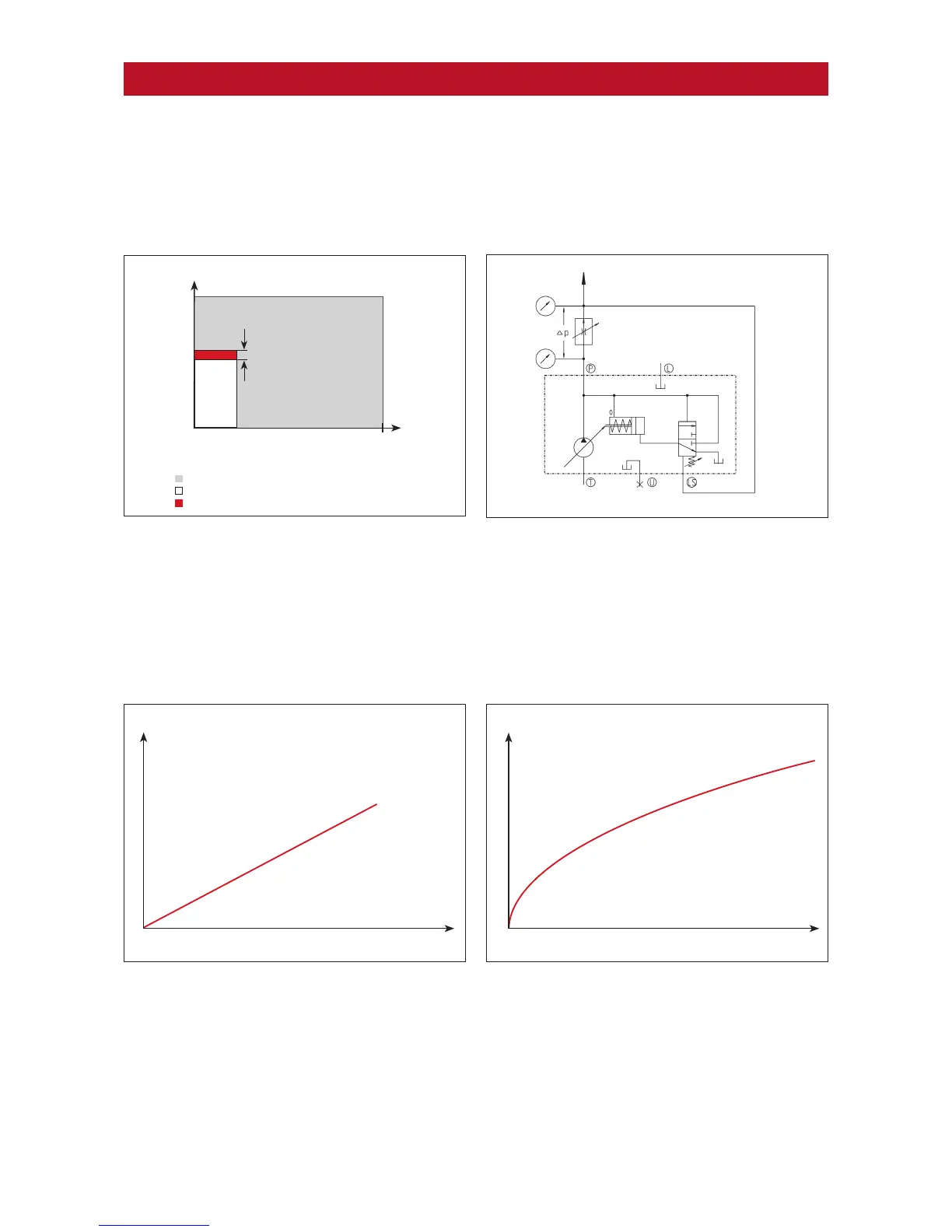

LS-function at ∆p = constant

Linde pumps with load sensing control enable the movement speed required of the selected actuator, e.g. of a boom, to be spe-

cified via the valve opening. The measured pump and load pressures are continuously balanced by the load sensing controller of

the hydraulic pump.

Benefits of LS-control

>> Any volume flow below the pump`s maximum can be set

>> Response speed of the machine can be defined

>> OEM-specific machine response is possible

>> Optimum precision control capability

Volume flow

A

Volume flow

∆p

A pressure gradient is set at the controller, which is defined by the actuator requirements. The volume flow results from the orifice A

of the control valve and the actual pressure gradient. Due to the LS-controller, the ∆p corresponds to the setting value. If the requi-

red volume flow differs, the pump displacement is changed accordingly. This happens automatically and reduces the effort required

by the operator. Since varying loads and varying numbers of actuators are compensated automatically. The ∆p LS basic setting is

possible from 16 to 27 bar with 20 bar as standard (the LS differential pressure influences the response times of the pump system).

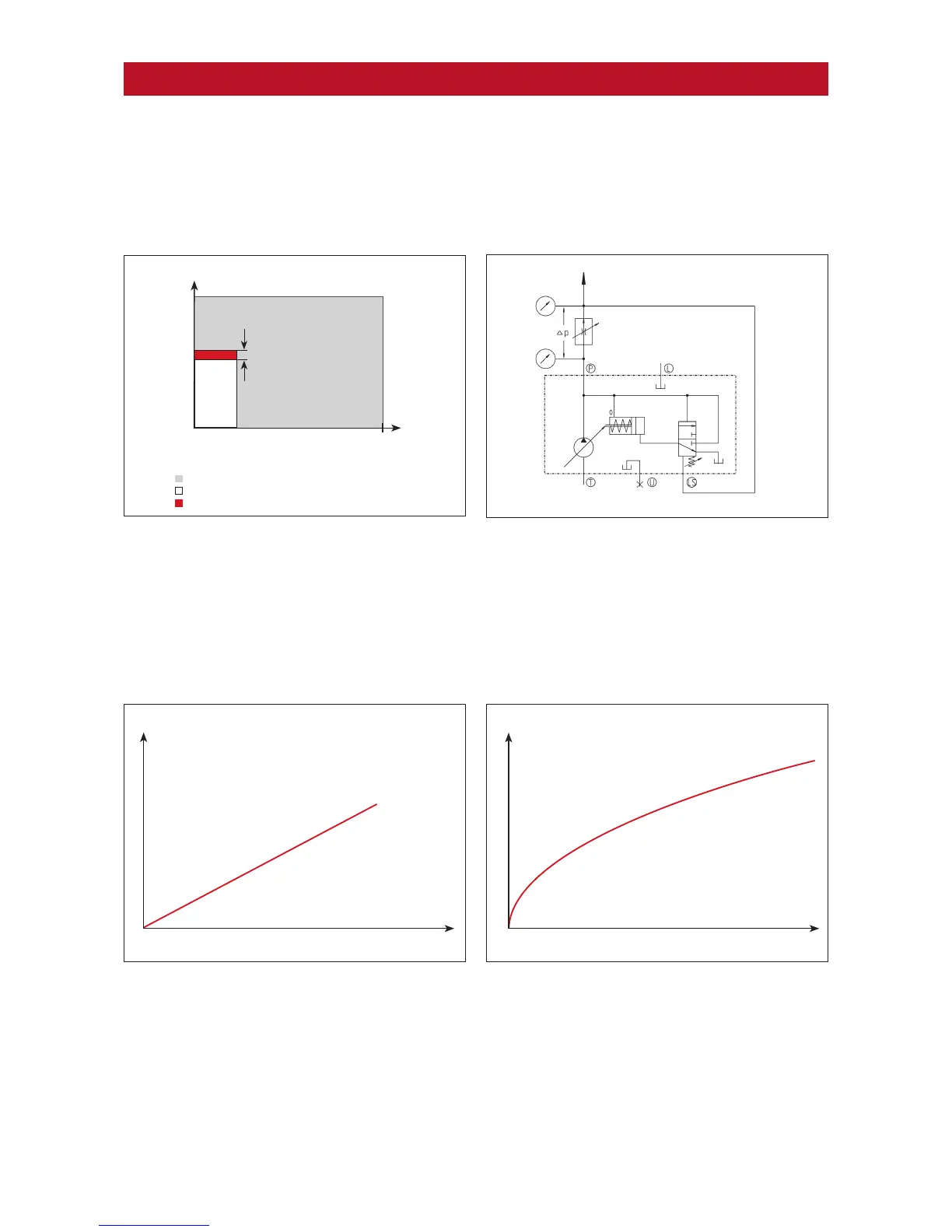

LS-function at area A = constant

Demand-oriented pump control offers the

following benefits

>> Load-independent machine control

>> Minimum heat generation

>> Increased pump service life

>> Low noise generation in the whole system

>> Fewer components for the control mechanism

>> Lower energy consumption, particularly with partial volume

flow

1 Flow

2 Pressure

Maximum performance range of the pump

Actual power demand of the system

Regulating ∆p

Load Sensing.

Flow on demand control

2

∆p

1

Q

max

Self-regulating pump with LS-controller

and measure orifice (in valve)

Towards actuator

LS-signal

Orifice

max.

Pump LS-controller

Loading...

Loading...