Page 4 of 12 TP1B001–1 English

Jun 2013

12

How To Use Dynamic Message

Orientation

Linx 5900

2.1.2 Software configuration

If the printer marks the products during the printhead movement, you must adjust the

printer settings as required to print the message correctly. If the printhead marks the

products in both the forward direction and the reverse direction, you must configure some

additional settings.

2.1.3 Software requirements

The 5900 Dairy Coder printer has a Variable Message Orientation option on the Print

Settings page which allows you to configure dynamic message orientation for traversing

applications (see ‘Set up dynamic message orientation’ on page 10.)

2.1.4 Inputs

A typical traversing application uses three input signals

Primary trigger

The primary trigger signal is normally a photocell. The photocell detects the presence of the

product on the production line as it approaches the printhead, and provides a ‘next object’

signal to the printer. The ‘next object’ signal starts a print delay, and the message is printed

after this delay. The position of the message on the product (print registration) depends on

the photocell position and delay. To get the correct print registration, these factors must be

carefully planned.

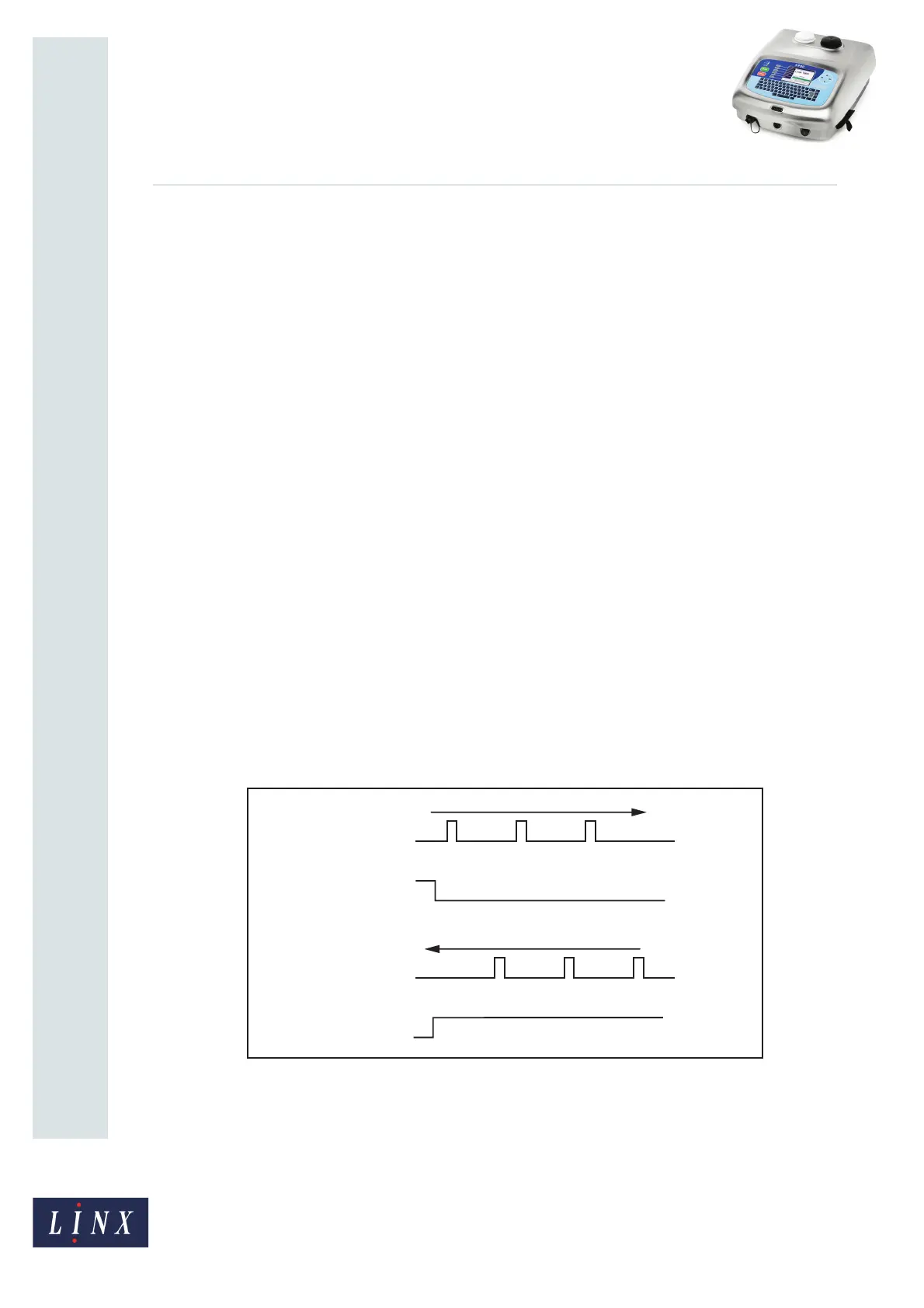

Secondary trigger

The secondary trigger signal provides the print ‘direction’ signal when the traversing arm is

at the end of its travel. The print ‘direction’ signal can set any sequential fields in the

message to their required values.

Figure 2. Print direction signal

123

LANE NUMBER

AUX. PHOTOCELL

FORWARD

NEXT OBJECT

123

LANE NUMBER

AUX. PHOTOCELL

REVERSE

NEXT OBJECT

AS361

Loading...

Loading...