Section 4 Disassembly and service

Stem –to- guide clearance

Subtract each valve stem OD from the corresponding

guide ID to obtain the guide-to-stem clearance.

If the stem-to-guide clearance exceeds the service

limit, determine if the new guide with standard

dimensions would bring the clearance within tolerance. If

so, replace the guide (or cylinder head ) as necessary and ream to fit. If the stem-to-guide

clearance exceeds the service limit with new guides, replace the valves as well.

Recondition the valve seat whenever the valve guide is replaced.

Cylinder head service

Exhaust valve guide replacement

The intake valve guide is not replaceable. If the

intake valve guide is worn beyond the service

limit,

Replace the cylinder head.

1. chill the replacement exhaust valve guide in

the freezer section of a refrigerator for about an

hour.

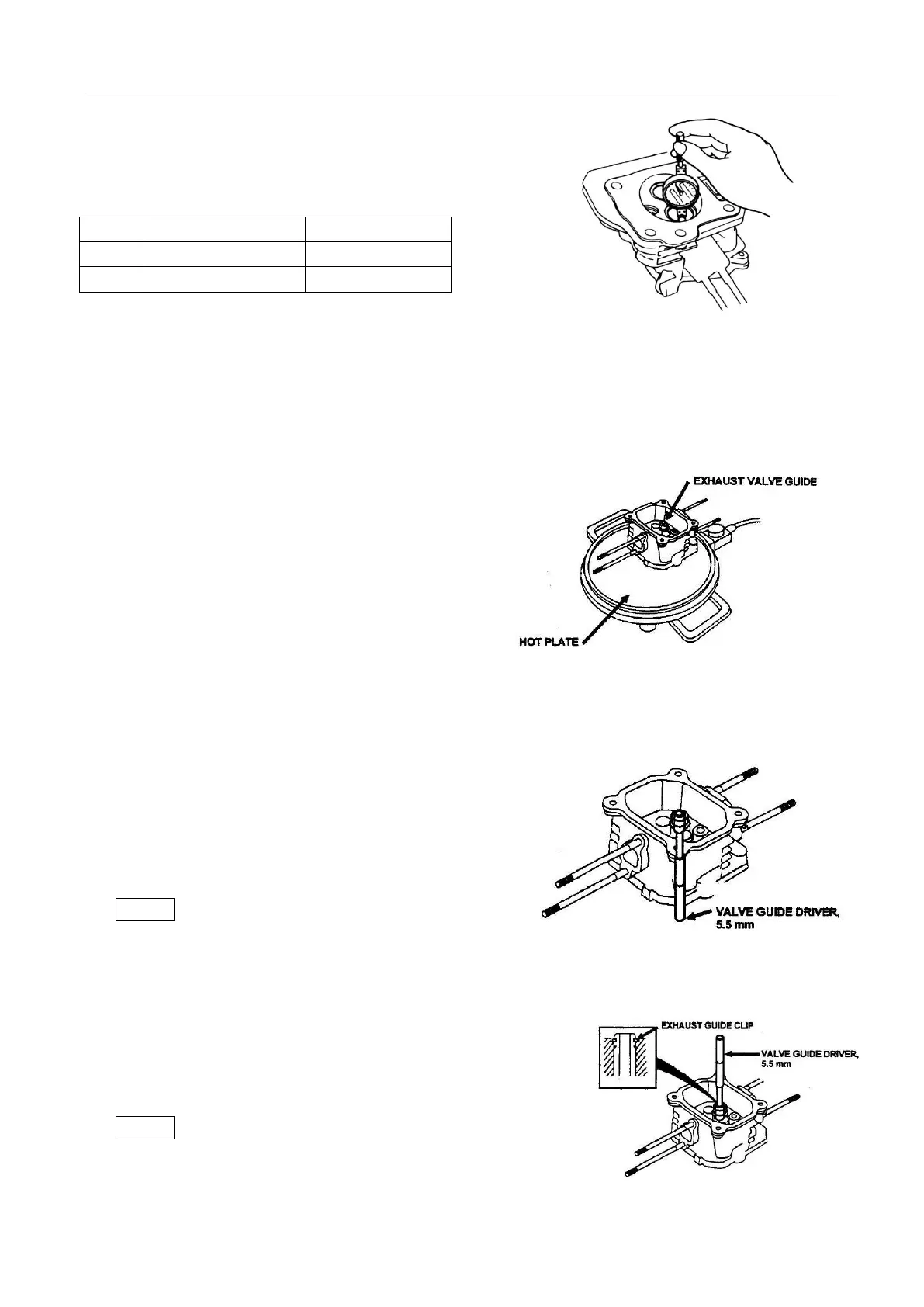

2. use a hot plate or oven to heat the cylinder

head evenly to 150℃(330℉)

Check the temperature with a temperature

indicating stick (available at welding supply

stores) or equivalent.

Wear heavy gloves to prevent burns when

handling heated cylinder head.

Notice

Do not use a torch to heat the cylinder head;

warpage of the cylinder head may result

Do not get the head hotter than 150℃(330℉);

excessive heat may loosen the valve seats.

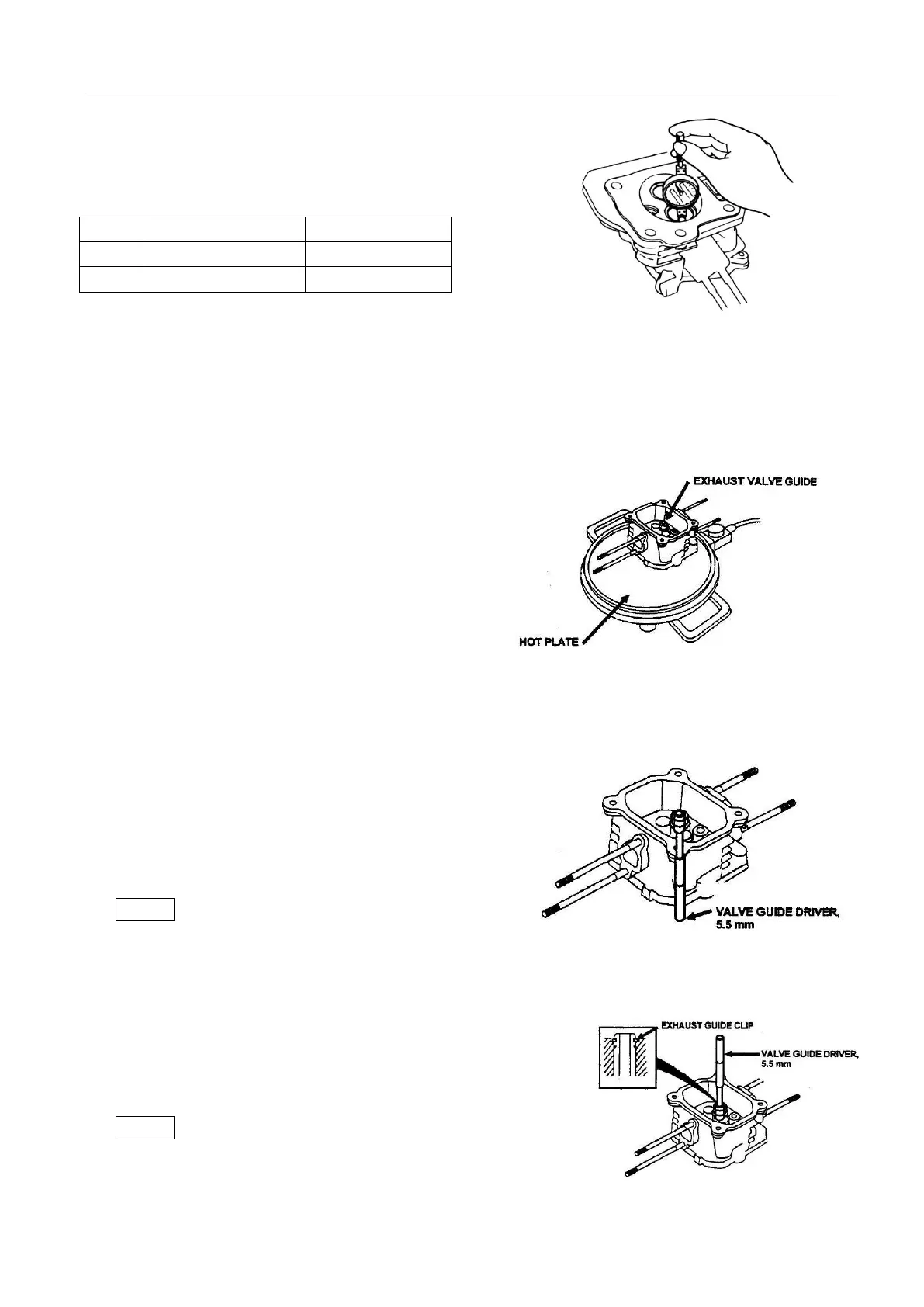

3. remove the heated cylinder head from the hot

plate and support it with wooden blocks. Drive

the exhaust valve guide out of the head from the

combustion chamber side.

Notice

When driving the valve guide out, be careful not to

damage the head.

4. remove the new exhaust valve guide from the refrigerator.

Loading...

Loading...