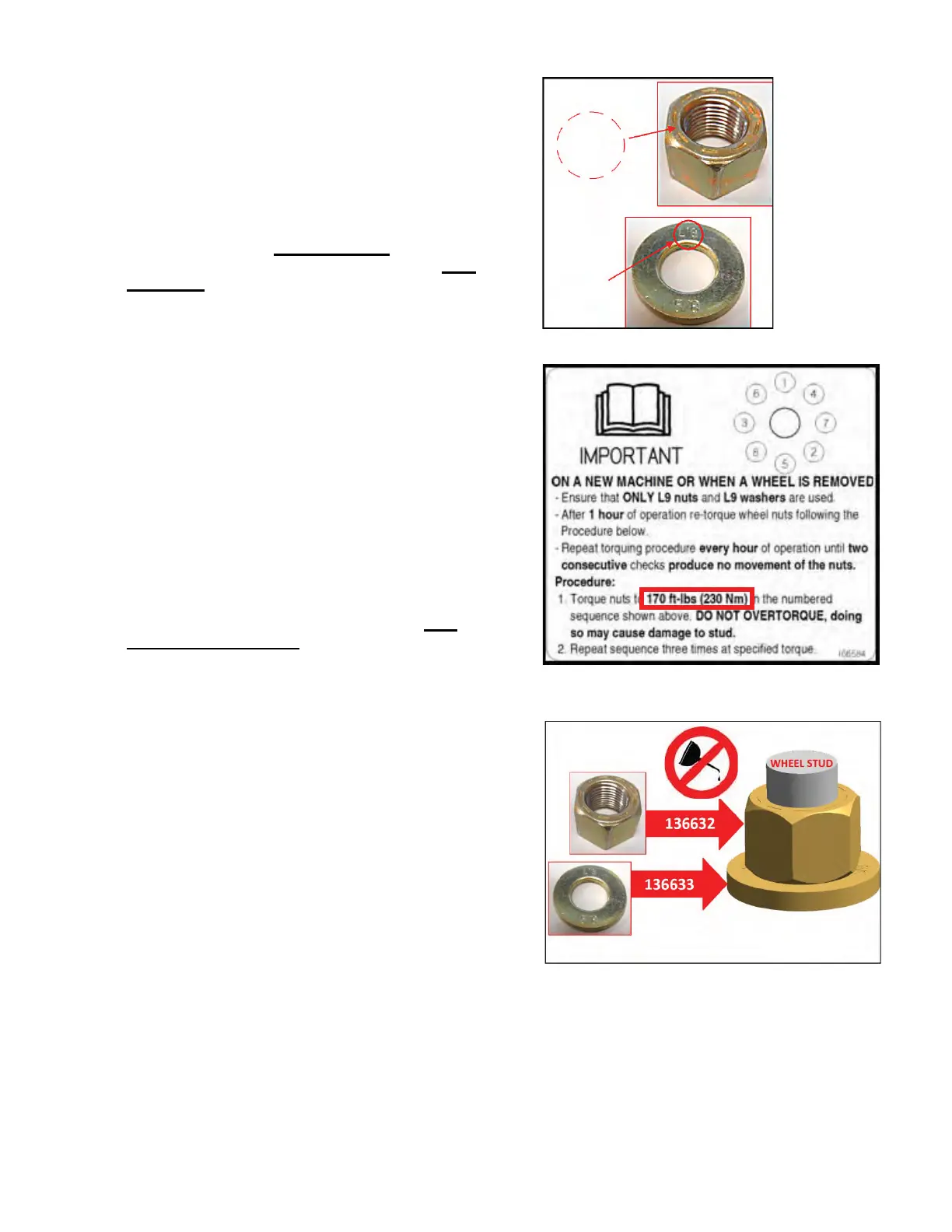

5. It is critical to ensure that the hardware is L9.

Verify as follows:

- Verify nut is L9 by ensuring it has 9 marks on one

side (See Figure 6)

- Verify washer is L9 by ensuring it has “L9” stamped

on one side (see Figure 6)

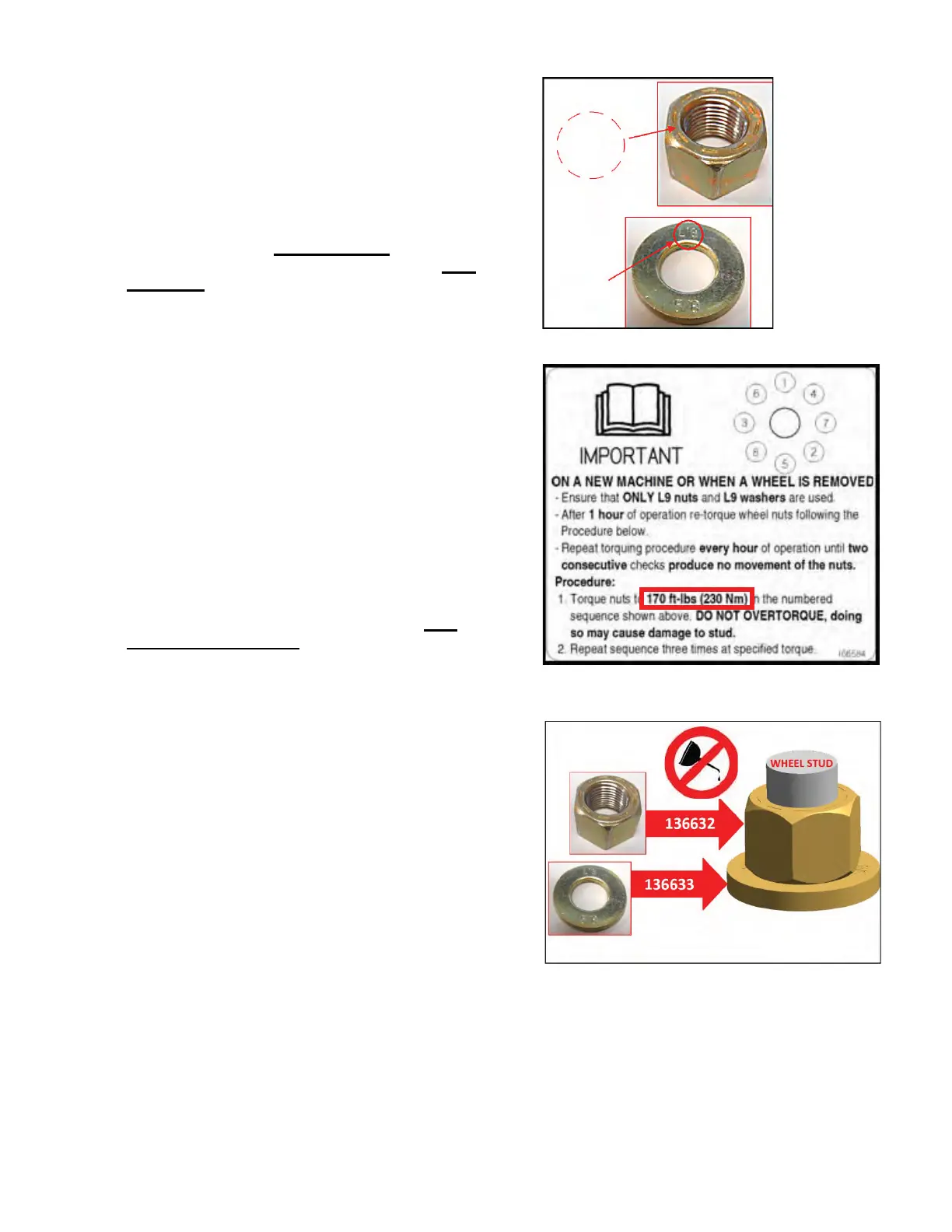

6. Mark each wheel stud at the 12 o’clock position.

Remove the old nuts ONE AT A TIME

and replace

with new washer and nut as per Step 7 and 8 ONE

AT A TIME in the numbered sequence shown on the

new drive wheel decal (Figure 7).

Check to see if the mark on the stud moves when the

nut is being removed. If the mark and stud are

moving, replace the wheel bolt.

7. Inspect the threads on each stud for damage. Spin on

nut only, by hand to check entire thread length to the

wheel rim. Remove nut, If thread damage is evident,

replace the wheel bolt.

For Auburn Gear drive wheels, use MD #49880

Wheel Bolt 5/8”NF x 60LG.

8. Inspect wheel bolt hole on the rim (that hole is

concentric around bolt) to see if there is any

elongation or wallowing out or other obvious damage.

If there is no damage replace old nut with the new

hardened washer and L9 nut. Thread the nut on using

hand tools only until they meet the washer. Nut

should be installed dry. Do not lubricate threads

with oil or products such as Never Seez®.

Tighten to 170 ft-lbs (230 Nm).

9. After inspecting wheel bolt holes, if multiple holes are

damaged this is an indication wheel bolt clamping

force was compromised. Replace the wheel rim and

all 8 wheel bolts. When (if) replacing wheel bolts, add

a couple of drops of a retaining compound such as

Loctite® 609

TM

to the knurled shoulder only, of the

new wheel bolt. Insert bolt till knurled shoulder

engages power wheel bolt hole engaging previous

knurling marks. Tap bolt in to seat head flush with

hub.

10. Along with new L9 hardware, it is important t

o adhere

to the new torque procedure as shown on the new

decal in Figure 7.

After all nuts are replaced, re-torque the new nuts to

170 ft-lbs (230 Nm) in the numbered sequence

shown on the decal.

DO NOT OVERTORQUE. Doing so may cause

damage to the stud.

Figure 6 – Nut And Washer Identification

Figure 7 – New Drive Wheel Decal With New

Torque Specification

Figure 8 – New L9 Nut And Washer

Form 169847 Revision A Pa

e 3 of 4

Loading...

Loading...