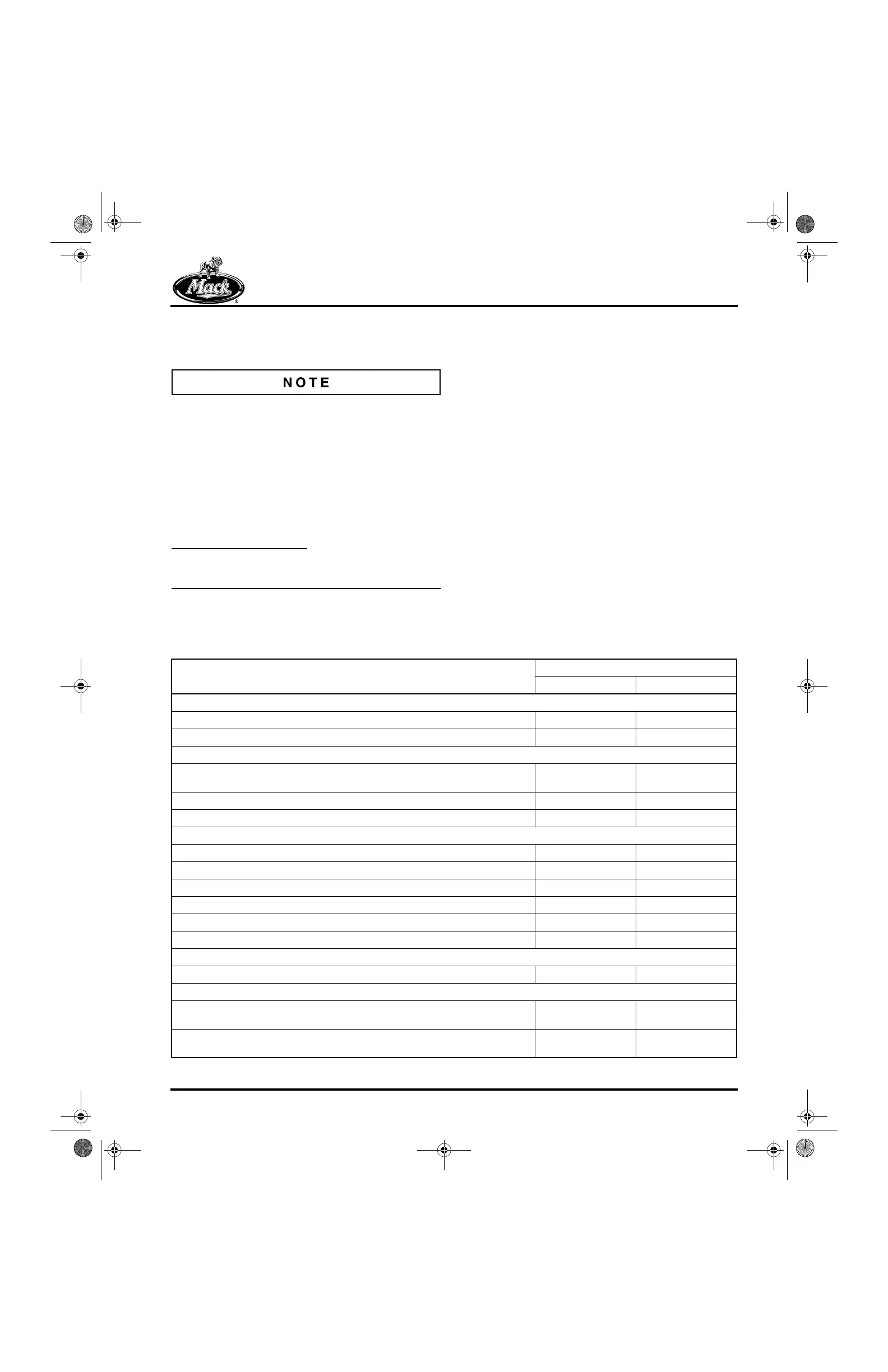

SPECIFICATIONS

Page 319

E-Tech™ Component Torque

Specifications

All components are to be clean and free from

foreign material or corrosion. Assemblies are to

be made using suitable tools and procedures so

that no permanent damage will occur as a result

of the assembly.

Threads, washer and underhead of screw or

washer face of nuts should be lubricated with

engine oil, unless otherwise specified.

The following listed fasteners require the use of a

calibrated manual torque

wrench.

Fasteners noted by a star * require retorque after

engine run-in.

TORQUE SPECIFICATIONS FOR CRITICAL FASTENERS

CRITICAL FASTENERS

Fastener Name

Torque

Lb-Ft N•m

AIR COMPRESSOR

Air Compr. Coupling to Air Compr. Retaining Nut 60 81

Air Compr. to Cyl. Block Mounting Screw 80 (Dry) 108 (Dry)

AUXILIARY DRIVE

Aux. Shaft Gear Retaining Nut (See “NOTE 1 — AUXILIARY SHAFT GEAR

RETAINING NUT INSTALLATION” on page 328.)

300 (Dry) 405 (Dry)

Aux. Shaft Thrust Washer to Block Screw 15 20

Aux. Shaft Hole Cover Stud Nut 40 55

BRAKE COMPONENTS — JACOBS

Oil Supply Screw 4-6 5-8

Jake Brake Housing Hold-Down Screw 45 61

Rocker Arm Adjusting Screw Jam Nut 40 55

Cyl. Head Cover Mounting Screw 16 22

Slave Piston Adjusting Screw Jam Nut 25 34

Yoke Adjusting Screw Nut (locknut on actuator pin screw) 33 44

CAMSHAFT

Camshaft Thrust Washer to Cyl. Block Screw 15 20

CONNECTING ROD

Connecting Rod Screw Angle Torque (Rods utilizing M14 threads, and cap-

to-rod alignment sleeves)

30 + 90° 41 + 90°

Connecting Rod Screw (Rod utilizing M16 threads, and no cap-to-rod

alignment sleeves)

150 203

5_106_00.bk Page 319 Friday, August 4, 2000 11:17 AM

BDC for engine manuals and specs

https://barringtondieselclub.co.za/

Loading...

Loading...