Tractor Roll Over

ROPS is a special safety unit. After an accident, The ROPS must be replaced so that you will get

the same protection as a new ROPS.

ROPS, the seat, the seat belts and all the mounting, accessories and wiring inside the operator’s

protective area must be carefully checked after a tractor accident and all parts with damage should

be replaced immediately. DO NOT TRY TO MAKE REPAIRS WELDING THE ROPS.

Safety Rules

1.Do not make modication to the ROPS. Example, welding an accessory to the ROPS, or drilling

a hole in the ROPS.

2.Special fasteners are used to install the operator protective parts. Replacement parts

must be the same as given in the Parts Catalog for your tractor.

ROPS Label

1.ROPS is equipped with a ROPS label.

2.The label contains the ROPS serial number and applicable standards.

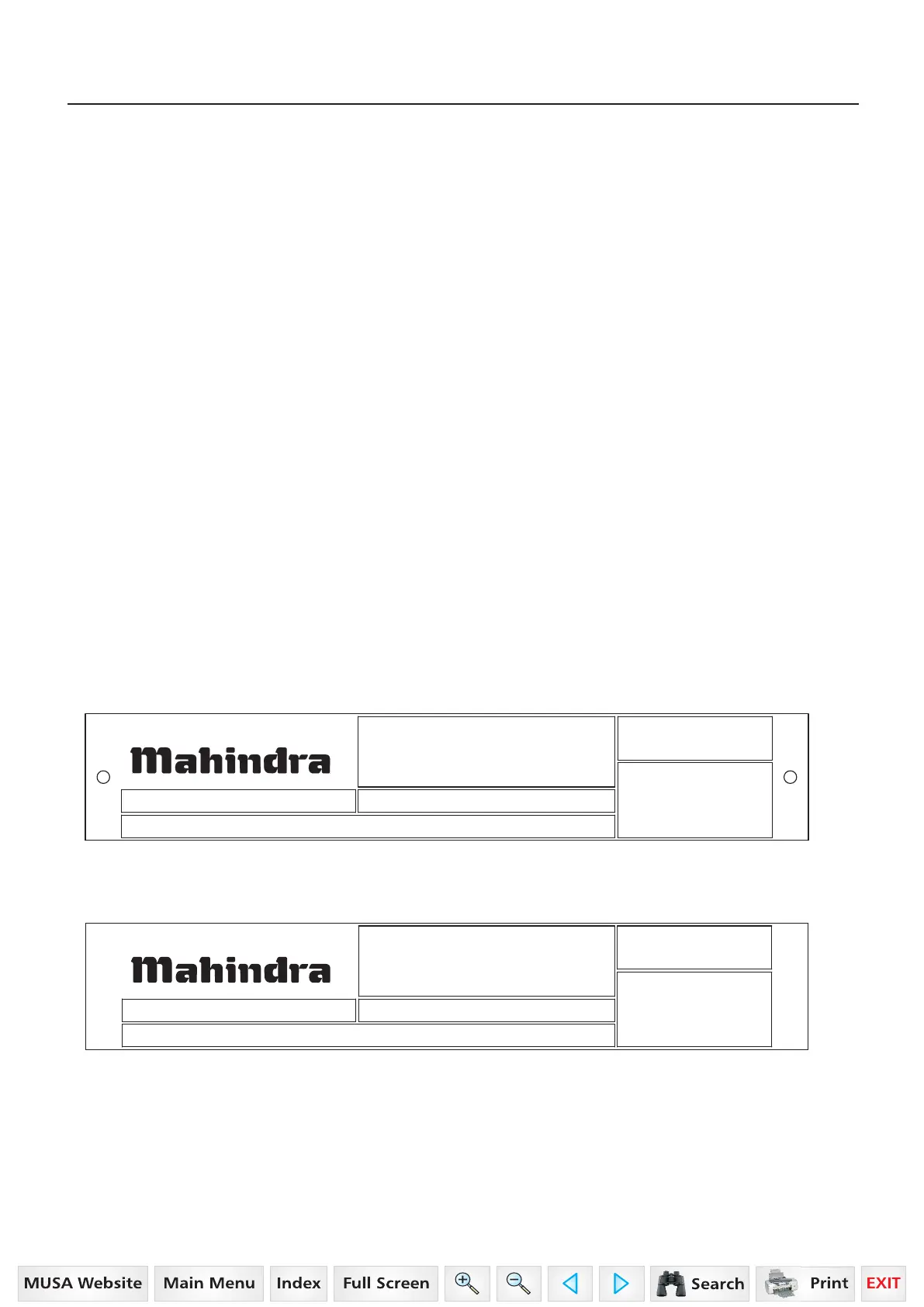

ROPS SERIAL NUMBER PLATE

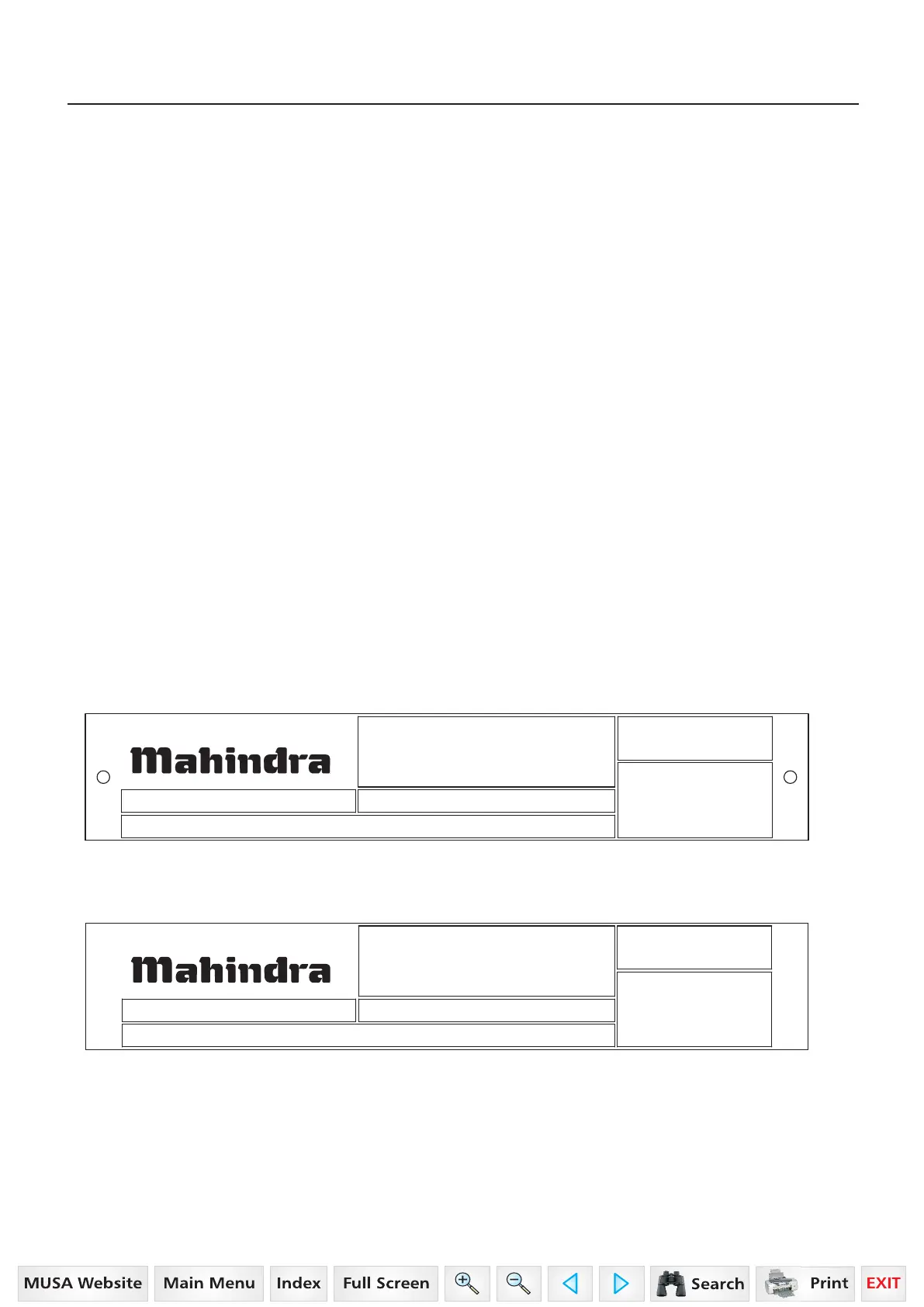

CABIN SERIAL NUMBER PLATE

ROPS

SERIAL No.

PERFORMANCE STANDARDS

MEASURED IN ACCORDANCE WITH

1928-C

FOR APPLICATION ON

MAHINDRA TRACTORS

3016,3016H,3616,3616H

SAE

J1194/

ROPS MODEL NO.

2HMM-6

TYPE-CERTIFICATION FOR

ROLLOVER

PROTECTIVE STRUCTURES

PROTECTION AFFORDED BY THIS ROPS

WILL BE REDUCED IF THE ROPS IS

ALTERED,HAS STRUCTURAL DAMAGE,

OR HAS BEEN SUBJECT TO UPSET.

SEE OPERATOR'S MANUAL FOR COM-

PLETE INSTRUCTIONS AND INSPECTION

REQUIREMENTS.

Made in Japan for

AGRICULTURAL Tractors

CONFORMS TO

OSHA REGULATION

ROPS

SERIAL No.

PERFORMANCE STANDARDS

MEASURED IN ACCORDANCE WITH

1928-C

FOR APPLICATION ON

MAHINDRA TRACTORS

3616X,3616HX

SAE

J1194/

ROPS MODEL NO.

CABM-1

TYPE-CERTIFICATION FOR

ROLLOVER

PROTECTIVE STRUCTURES

PROTECTION AFFORDED BY THIS ROPS

WILL BE REDUCED IF THE ROPS IS

ALTERED,HAS STRUCTURAL DAMAGE,

OR HAS BEEN SUBJECT TO UPSET.

SEE OPERATOR'S MANUAL FOR COM-

PLETE INSTRUCTIONS AND INSPECTION

REQUIREMENTS.

Made in Japan for

AGRICULTURAL Tractors

CONFORMS TO

OSHA REGULATION

Loading...

Loading...