3 - 9

A5/2

A5/1

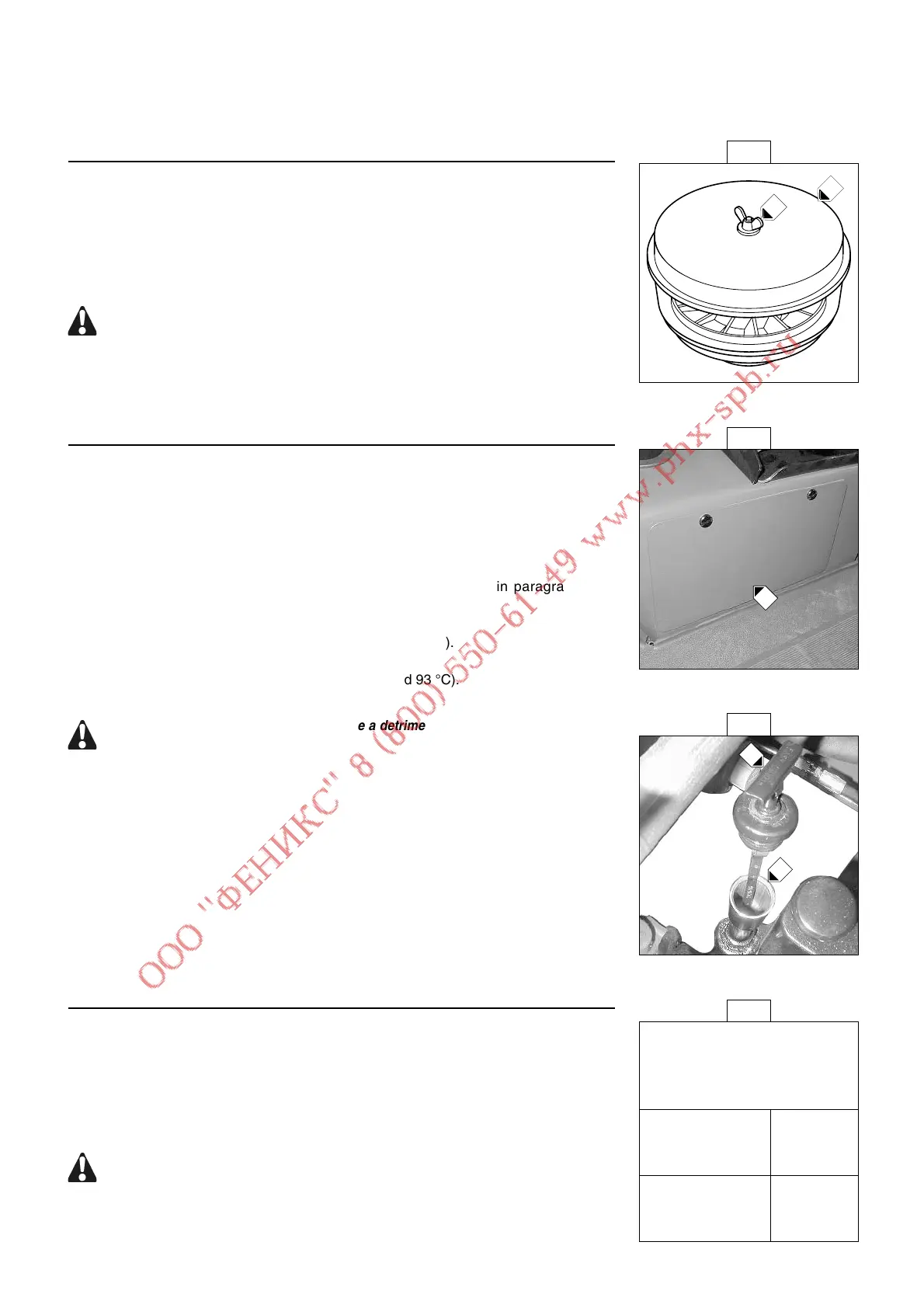

A4 - CYCLONIC PREFILTER (OPTION)

CLEAN

The cleaning interval is given as a guide, however the prefilter must be emptied as soon

as impurities reach the MAXI level on the tank.

- Loosen nut 1 (Fig. A4), remove cover 2 (Fig. A4) and empty the tank.

- Clean the prefilter unit with a clean dry cloth and reassemble the unit.

When cleaning, take care not to let impurities into the dry air filter.

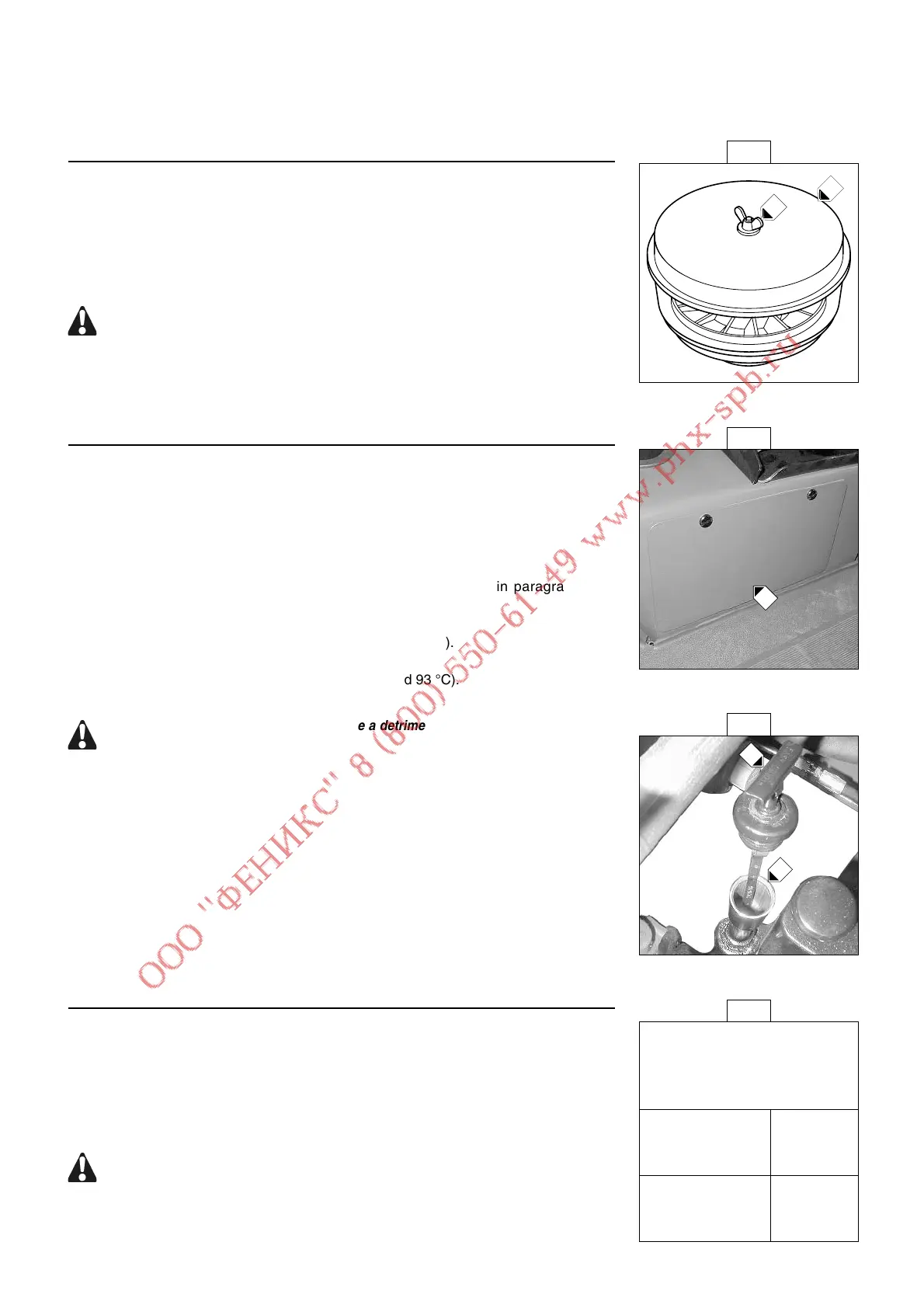

A5 - TRANSMISSION OIL LEVEL

CHECK

Place the lift truck on level ground with the I.C. engine cold and at idle.

- Disassemble the access panel 1 (Fig. A5/1).

- Remove the dipstick 2 (Fig. A5/2).

- Check the level of the lower notch.

- If necessary, add oil (See chapter : LUBRICANTS AND FUEL in paragraph : 3 -

MAINTENANCE) by the filler port 3 (Fig. A5/2).

NOTE : OIL LEVEL WHEN COLD (Between 15 °C and 20 °C).

Oil level must be at lower notch.

OIL LEVEL WHEN WARM (Between 82 °C and 93 °C).

Oil level must be at upper notch.

Too much oil in the transmission may have a detrimental effect on the functioning of

the lift truck.

A6 - TYRES PRESSURE AND WHEEL NUTS TORQUE

CHECK

- Check the condition of the tyres, to detect cuts, protuberances, wear, etc.

- Check the torque load of the wheel nuts (Fig. A6). Non compliance with this instruction

can cause damage and rupture to the wheel bolts and distortion to the wheels.

- Check and adjust the tyre pressures if necessary (See chapter : CHARACTERISTICS

paragraph : 2 - DESCRIPTION).

Check that the air hose is correctly connected to the tyre valve before inflating and

keep all persons at a distance during inflation. Respect the recommended tyre

pressures given.

A4

340 ± 15 %

N. m

630 ± 15 %

N. m

A6

WHEEL NUTS

TIGHTENING TORQUE

FRONT TYRES

REAR TYRES

1

2

3

1

2

Loading...

Loading...